Area

60000㎡Number of workers

Over 300 workersProduct

Welded Pipe,Lsaw steel pipeFacility

Beveling Machine, Hot Induction Bend Making, Extruding Machine, Heat Treatment FurnaceAnnual output

200000 tonnes for LSAW pipe

Factory introduction

Factory introduction

The factory currently has UOE, JCOE (5 lines),

HFW, COE,There are 15 welded pipe production

lines including three-roll forming (2 lines),and

composite pipelines, equipped with internal and

external anti-corrosion and cement counterweight production lines,with an annual production capacity

of 3.78 million tons.

The factory can supply 406mm-1829mm (16"-72")

large straight seam double-sided submerged arc

welded pipe (SAWL),610mm-7000mm (24"-276")

three-roll welded pipe, 406mm-1219mm

(16"-48") corrosion-resistant alloy (CRA)liner/lined compositesteel pipe and 406mm-1524mm

(16"-60") stainless steelwelded pipe, and

supply FBE,3LPE/3LPP,polyurethane,cement

counter weight,asphalt,cement andother

forms of anti-corrosionsteel pipesand

various bends, elbows, different Diameter

pipes,tees, crosses, pressurevessels,

spinning heads,flanges and other pipe fittings.

Our products comply with various international

standards, such as API5L/5CT/2B/5LD, ASTM,

DNV, ISO,DIN, EN, BS, CE, CSA, etc.Products are

widely used in oil, natural gas, petrochemical,

mining, electric power, coal chemical, marine

engineering, infrastructure engineering, steel

structures and supply water and other fields.

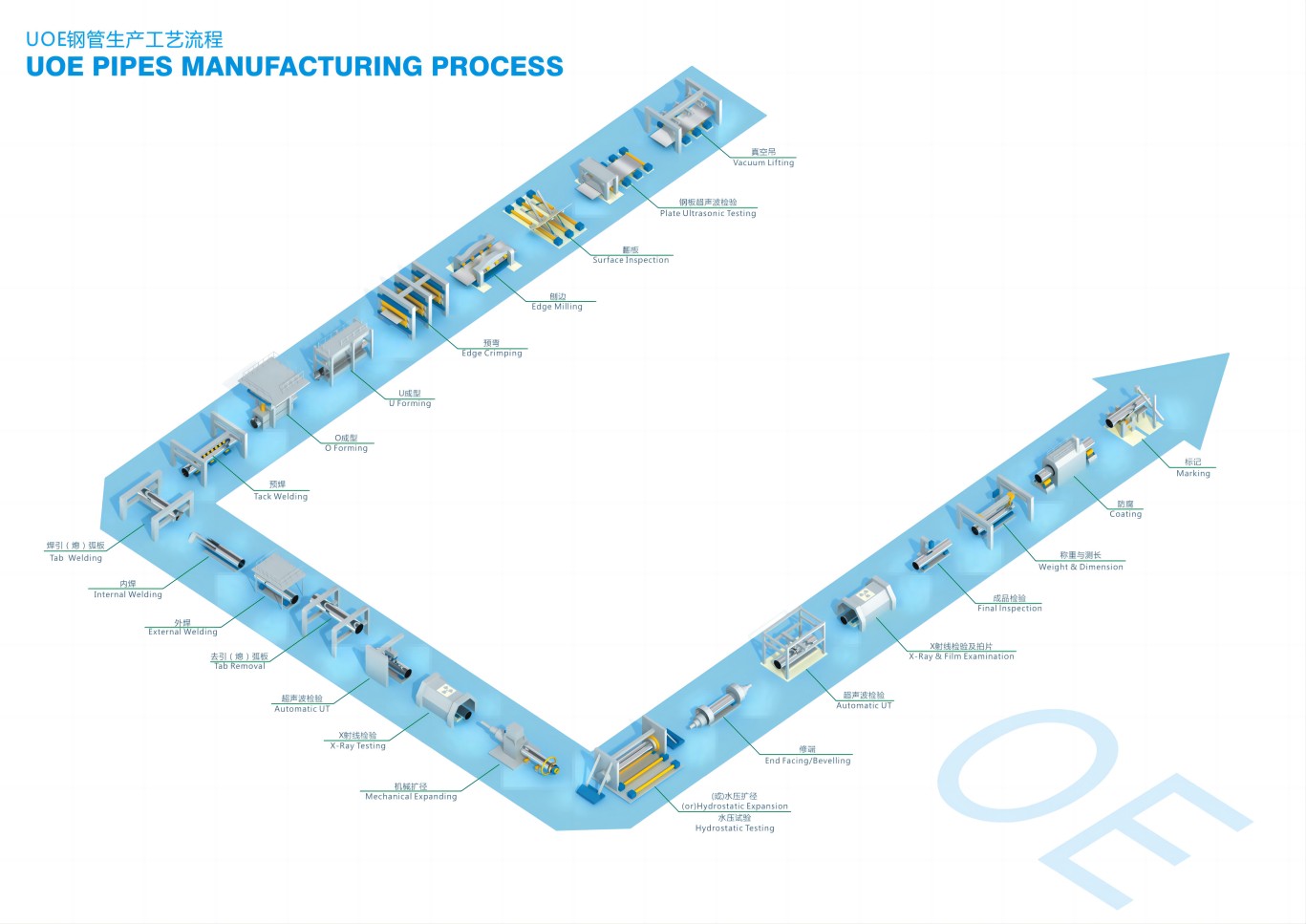

UOE pipe is a type of longitudinally welded steel pipe produced using the UOE method, which involves crimping, U-pressing, O-pressing, and expanding.

UOE is more suitable for the production of single-size, high-volume products

Specifications

UOE pipes size range:

Outside Diameter: Φ508mm- 1118mm (20"- 44")

Wall Thickness: 6.0mm-30.0mm(1/4"-1")

Length: 9m-12.3m (30'- 40')

Quality Standards: API、DNV、ISO、DEP、EN、ASTM、DIN、BS、GB、CSA

Grades: API 5L A-X90,GB/T9711 L190-L625

In accordance with different requirements of the customers, the welded pipe can be expanded either by mechanical or hydrostatic expander to improve dimensional accuracy, and eliminate residual stress.

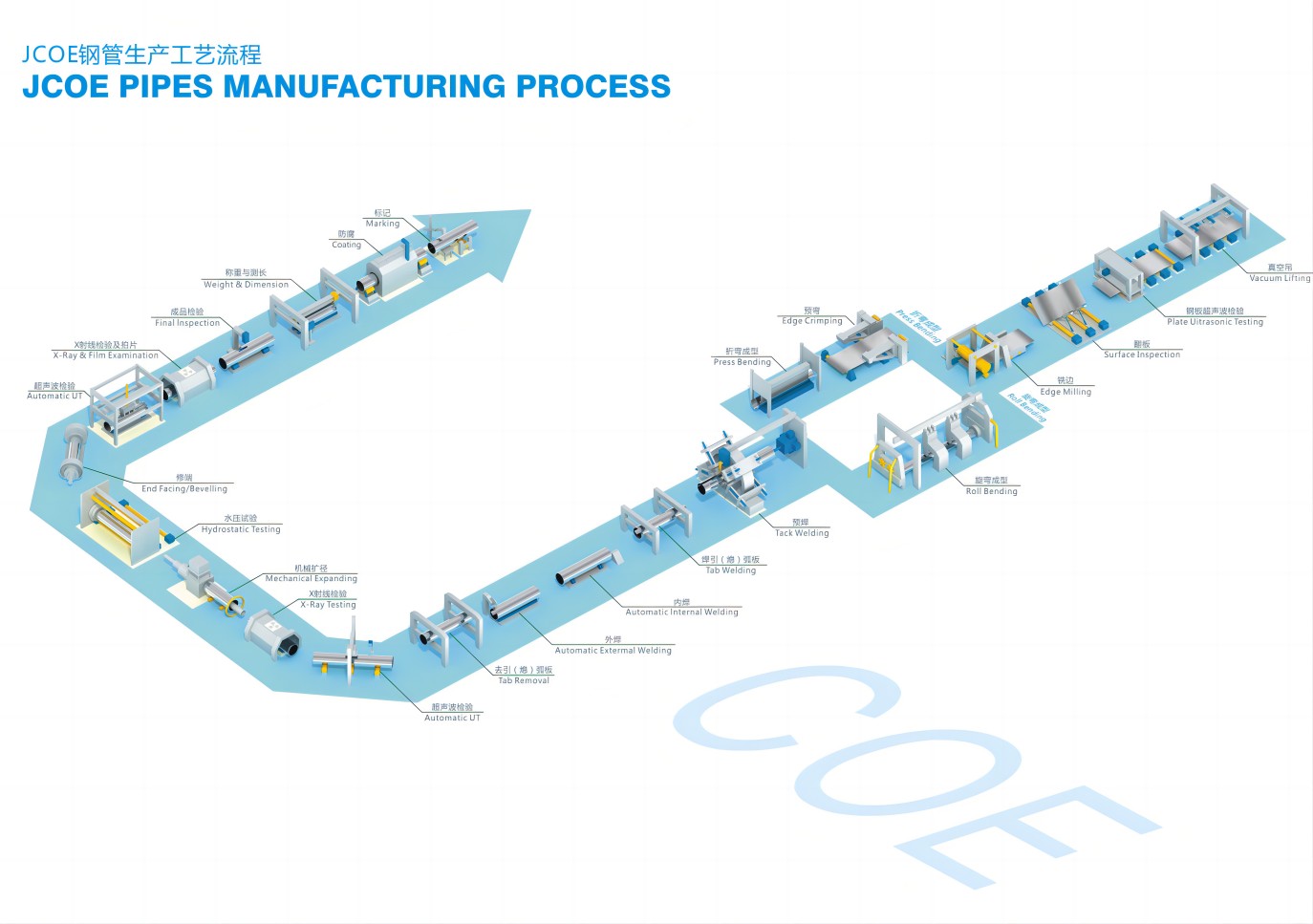

JCOE Pipe refers to a type of longitudinally submerged arc-welded (LSAW) steel pipe that is produced using the JCOE forming process.

The mill adopts continuous axis contorting J-C-O(J-ing, C-ing and O-ing)process with characteristics of high forming accuracy and efficiency as well as balanced distribution of forming stress.

Specifications

Throughput: 300,000 MT

Outside Diameter :Φ406-Φ1829mm (16″-72″)

Wall Thickness :6.0-25.4mm (1/4″-1″)

Length :3-12.2m (10′-40′)

Ouality Standards :API, BS, ASTM , JIS, DIN, GB , ISO, DNV

Grades :GB/T9711 L190-L555(API 5L A-X80)

We are able to provide customers with quality products and perfect service.

USI Group has a quality inspection center to provide inspection services for the production process and finished products,Learn more about the Inspection process!

Continuous Welding Production Line

Continuous Welding Production Line

Continuous Welding Production Line

Continuous Welding Production Line

JCO Large-caliber Single Forming Production Line

JCO Large-caliber Single Forming Production Line

JCO Large-caliber Single Forming Production Line

JCO Large-caliber Single Forming Production Line