-

2024-04-03Pipe Standard

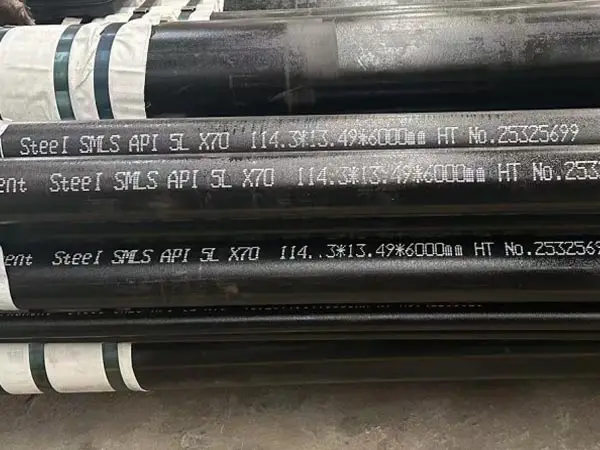

X70 Line steel Pipe

API 5L X70 pipe is a premium grade piping material in API 5L standard specifications. Also called L485 pipe, as it’s yield strength minimum in 485 Mpa (70,300 psi). API 5L X70 covers manufacturing types in seamless and welded (ERW, SAW) types, both applied for oil and gas transmissions.

-

2023-12-15Pipe Standard

Q345B low alloy seamless steel pipe

Q345B low alloy seamless steel pipe has many classification methods. According to the manufacturing process, there are: hot-rolled seamless steel pipe and cold-rolled seamless steel pipe. According to the use, there are: seamless steel pipe for general structure, seamless steel pipe for transporting fluids.

-

2023-12-15Pipe Standard

P91 alloy pipe

According to different production methods, it can be divided into hot-rolled pipes, cold-rolled pipes, cold-drawn pipes, extruded pipes, etc.

1.1. Hot-rolled P91 alloy pipes are generally produced on automatic pipe rolling units. The solid tube blank is inspected and surface defects are removed, cut into the required length, centered on the perforated end of the tube blank, and then sent to the heating furnace for heating and piercing on the punching machine. It continues to rotate and advance during piercing holes. Under the influence of the rollers and the end, the tube blank is hollow gradually, which is called gross pipe. Then it is sent to the automatic pipe rolling machine to continue rolling. Finally, the wall thickness is evened by the leveling machine, and the diameter is determined by the sizing machine to meet the specification requirements. The use of continuous pipe rolling units to produce hot-rolled P91 alloy pipes is a more advanced method.

1.2. If you want to obtain seamless steel pipes with smaller size and better quality, you must use cold rolling, cold drawing or a combination of the two. Cold rolling is usually carried out on a two-roll mill, and the steel pipe is rolled in an annular pass composed of a variable cross-section circular groove and a fixed conical head. Cold drawing is usually performed on a 0.5 to 100T single-chain or double-chain cold drawing machine.

1.3. The extrusion method is to place the heated tube blank in a closed extrusion cylinder, and the perforation rod and the extrusion rod move together to make the extrusion part extruded from the smaller die hole. This method can produce steel pipes with smaller diameters.

-

2023-12-08Pipe Standard

ASTM A178 ERW Steel Pipe

ASTM A178 is a specification that covers minimum-wall-thickness, electric-resistance-welded tubes made of carbon steel and carbon-manganese steel. These tubes are intended for use as boiler tubes, boiler flues, superheater flues, and safe ends in boilers.

ASTM A178 ERW Steel Pipe Features

-

2023-08-08Pipe Standard

Cold formed EN 10219 S275J0H rectangular hollow sections

Cold formed EN 10219 S275J0H rectangular hollow sections are a type of steel pipes that are widely used in various structural applications. These hollow sections are produced through a cold forming process, which involves shaping the steel at ambient temperature.

EN 10219 is a European standard that specifies the technical delivery conditions for cold formed welded structural hollow sections of non-alloy and fine grain steels. This standard ensures that the hollow sections meet specific requirements in terms of dimensions, tolerances, mechanical properties, and other relevant characteristics

Rectangular pipes made from cold formed structural steel offer several advantages. They have high strength-to-weight ratio, making them suitable for lightweight construction projects,construction, infrastructure, and manufacturing. Additionally, their rectangular shape provides enhanced load-bearing capacity and facilitates efficient space utilization.

When it comes to section properties, EN 10219 S275J0H rectangular hollow sections exhibit excellent stiffness and resistance to bending and torsion forces. The wall thickness of these pipes can vary depending on the specific application requirements.

-

2023-06-29Pipe Standard

Grades and Specifications for API 5L Pipe

Grades and Specifications for API 5L Pipe

-

2023-06-09Pipe Standard

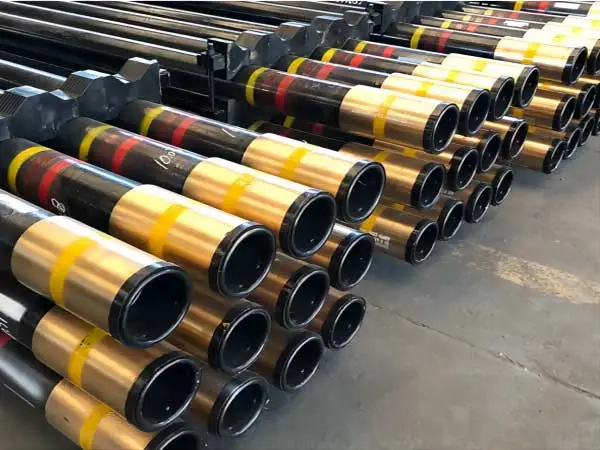

L80-13Cr tubing

Introduced L80- 13Cr special thread thickened tubing. By analyzing the deformation characteristics of L80-13Cr steel and combining the actual production experience, the pipe end thickening process is determined; by analyzing the mechanical properties of L80-13Cr steel, the austenitization temperature is set The heat treatment scheme of natural cooling to below 50°C in the air. The test results show that: the size and microstructure of the thickening end of the L80-13Cr special thread thickening oil pipe meet the design requirements, and the mechanical properties of the pipe body and pipe end are uniform; the tensile properties, impact toughness and hardness all meet API Spec 5CT-2011 specification requirements.

-

2023-06-05Pipe Standard

specifications of API 5CT Grade N80 oil casing

API 5CT Grade N80 oil casing is a high-strength, high-toughness carbon seamless steel pipe. Commonly used methods are: quenching and tempering (including direct quenching + tempering after rolling), normalizing, normalizing + tempering, and tempering after rolling. fire. 36Mn2V is the steel used for the production of N80 oil casing, which belongs to microalloyed non-quenched and tempered steel. The steel is suitable for processing by methods such as temperature control, cooling control, and deformation control. The steel pipe can achieve the required performance without quenching and tempering, which simplifies the production process and reduces the manufacturing cost of the steel pipe.