|

ASTM Specification |

ASTM B 167 ASME SB 167 / ASTM B 725 ASME SB 725 |

|

Standard |

ASTM, ASME, JIS, AISI, AMS, EN, SAE, DIN, NF, TOCT, DS, DTD, |

|

ASTM B167 inconel Seamless Pipe Size |

4 to 219mm W. T.: 0.5 to 20mm |

|

Incoloy Welded Pipe Size |

5.0 - 1219.2 mm |

|

Inconel ASME SB725 Inconel Alloy EFW Pipe size |

5.0 - 1219.2 mm |

Inconel Pipe Specification

Inconel Pipe Specification

|

ASTM Specification |

ASTM B 167 ASME SB 167 / ASTM B 725 ASME SB 725 |

|

Standard |

ASTM, ASME, JIS, AISI, AMS, EN, SAE, DIN, NF, TOCT, DS, DTD, |

|

ASTM B167 inconel Seamless Pipe Size |

4 to 219mm W. T.: 0.5 to 20mm |

|

Incoloy Welded Pipe Size |

5.0 - 1219.2 mm |

|

Inconel ASME SB725 Inconel Alloy EFW Pipe size |

5.0 - 1219.2 mm |

|

Swg & Bwg |

12 Swg., 10 Swg., 16 Swg., 14 Swg., 20 Swg., 18 Swg., |

|

inconel Pipe Schedule |

XS, SCH30, SCH40, XXS, SCH80, SCH120, SCH60, SCH140, STD, SCH10, SCH10S, SCH40S, SCH80, SCH20, SCH5, SCH160 |

|

inconel pipe Length |

Double Random, Single Random, Standard & Cut length Pipe |

|

Finish |

Polished, AP (Annealed & Pickled), BA (Bright & Annealed), MF, NO.1, NO.4, 2B, BA, HL, 8K, Mirror finish, etc |

|

Form |

inconel are available in form of Round, Square, Hollow, Rectangular, Hydraulic, Coiled, Straight Pipes, “U” Shape, Pan Cake Coils etc. |

|

Type of 600 Alloy Pipe |

Seamless / ERW/ EFW / Welded / Fabricated / CDW / DOM / CEW inconel |

|

inconel pipeEnd |

Plain End, Beveled End, Treaded Pipe, Screwed ends |

|

Marking on ASTM B167 Inconel Pipe |

All ASTM B167 inconel Pipes are marked as follows: Standard, Grade, OD, Thickness, Length, Heat No. (Or according to the customer’s request.) |

|

Application of inconel pipe |

Dairy Pipe, Oil Pipe, Gas Pipe, Fluid Pipe, Boiler Pipe for Chemical Industry |

|

Value Added Service |

Draw & Expansion as per required Size & Length, Polish (Electro & Commercial) Annealed & Pickled Bending, Machining Etc. |

|

Specialize in |

Large Diameter inconel pipe |

|

inconel pipe manufacturing Technique |

Cold drawn, hot drawn, bright annealed, solid solution, hot extruding |

|

Our stockyard |

Noida, Ahmedabad, Chennai, Bengaluru, Hyderabad, Tiruchirappalli, Shivamogga, Bhubaneswar, Pune, Dhanbad, Agra, Coimbatore, Tirunelveli, Mumbai, Thiruvananthapuram, Navi Mumbai, Pimpri-Chinchwad, |

|

inconel pipe Test Certificate |

Manufacturer Test Certificate |

|

Material Test Certificates (MTC) |

Material Test Certificates (MTC) as per EN 10204/3.1B, EN 10204 3.1 and EN 10204 3.2, 100% Radiography Test Report, Heat Treatment Charts, Raw Materials Certificate, Third Party Inspection Report, Fumigation Certificates, inconel HS Code Commercial Invoice, Form A for Generalized System of Preferences (GSP) |

|

Manufacturers of inconel pipe |

· inconel Pipe make Tubacex Tubos Inoxidables S.A., Spain · inconel Pipe make Nippon Steel Corporation, Japan · inconel Pipe make Sumitomo Metals, Japan · ASTM B167 Inconel Seamless Pipe make Seah Steel Corporation, Korea · ASTM B167 Inconel Pipe make Kobe Special Tube, Japan · ASTM B167 Inconel Pipe make Schoeller Bleckmann, Austria · inconel Pipe make Sanyo Special Steel, Japan |

|

We can also cut, thread, and groove Incoloy Pipe to meet your specifications. inconel pipe Dimension ANSI/ ASME B36.10, B36.19, B2.1 |

|

Incoloy 800/800HT/825 Pipes and Tubes Other Types

Incoloy 800/800HT/825 Pipes and Tubes Other Types

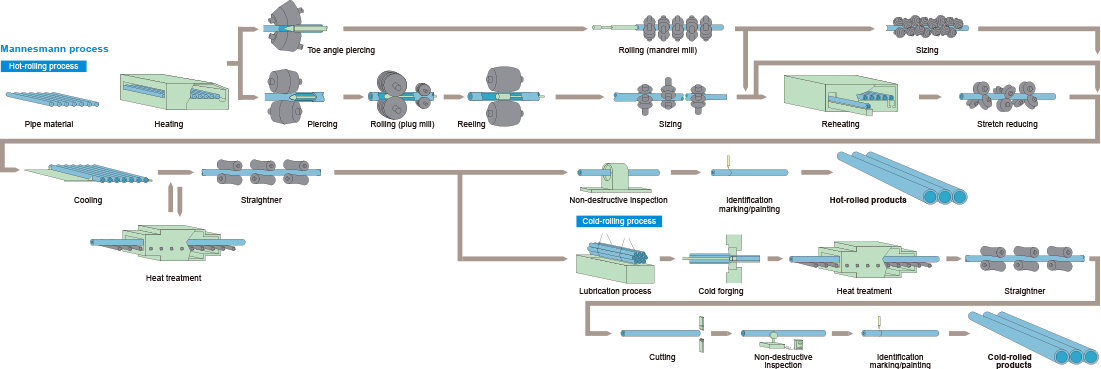

Seamless pipes & tubes (Mannesmann process)

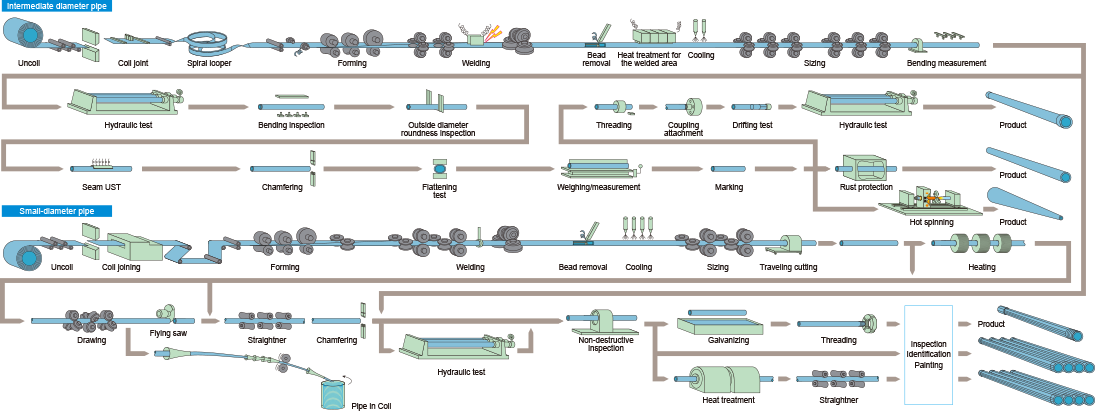

Electric resistance-welded pipes & tubes

Micro and Macro Test

Positive Material Identification – PMI TestingMechanical Testing Such as Tensile of Area

Inconel Pipe Chemical Composition

Inconel Pipe Chemical Composition

|

Inconel |

Element (% By Mass) |

||||||||||||||

|

Ni |

Cr |

Fe |

Mo |

Nb |

Co |

Mn |

Cu |

Al |

Ti |

Si |

C |

S |

P |

B |

|

|

600 |

72.0 |

14.0–17.0 |

6.0–10.0 |

|

|

|

1.0 |

0.5 |

|

|

0.5 |

0.15 |

0.015 |

|

|

|

617 |

44.2–56.0 |

20.0–24.0 |

3.0 |

8.0–10.0 |

|

10.0–15.0 |

0.5 |

0.5 |

0.8–1.5 |

0.6 |

0.5 |

0.15 |

0.015 |

0.015 |

0.006 |

|

625 |

58.0 |

20.0–23.0 |

5.0 |

8.0–10.0 |

3.15–4.15 |

1.0 |

0.5 |

|

0.4 |

0.4 |

0.5 |

0.1 |

0.015 |

0.015 |

|

|

690 |

59.5 |

30 |

9.2 |

|

|

|

0.35 |

0.01 |

0.02 |

|

0.35 |

0.019 |

0.003 |

|

|

|

718 |

50.0–55.0 |

17.0–21.0 |

Balance |

2.8–3.3 |

4.75–5.5 |

1.0 |

0.35 |

0.2–0.8 |

0.65–1.15 |

0.3 |

0.35 |

0.08 |

0.015 |

0.015 |

0.006 |

|

X-750 |

70.0 |

14.0–17.0 |

5.0–9.0 |

|

0.7–1.2 |

1.0 |

1.0 |

0.5 |

0.4–1.0 |

2.25–2.75 |

0.5 |

0.08 |

0.01 |

|

|

Inconel Pipe Mechanical Properties

Inconel Pipe Mechanical Properties

| Tensile Strength (MPa) min | Yield Strength 0.2% Proof (MPa) min | Elongation (% in 50mm) min | Hardness | |

| Rockwell B (HR B) max | Brinell (HB) max | |||

| Psi – 1,35,000 , MPa -930 | Psi – 75,000 , MPa – 517 | 42.5 | – | – |

Inconel Pipe Standrard

Inconel Pipe Standrard| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN | OR |

| Incoloy 800 Pipe | 1.4876 | N08800 | NCF 800 | NA 15 | ЭИ670 | Z8NC32-21 | X10NiCrAlTi32-20 | XH32T |

| Incoloy 800H Pipe | 1.4958 / 1.4876 | N08810 | NCF 800H | NA 15(H) | ЭИ670 | Z8NC33-21 | X5NiCrAlTi31-20 | XH32T |

| Incoloy 800HT Pipe | 1.4859 / 1.4876 | N08811 | NCF 800HT | NA 15(HT) | ЭИ670 | – | X8NiCrAlTi32-21 | XH32 |

HuNan Province

+86-731-85648266

LiaoNing Province

+86-731-85648266

HeBei Province

+86-731-85648299

jiangsu Province

+86-731-85648299

TianJin City

Singapore