|

Slot size |

0.10, 0.15, 0.20, 0.25, 0.30…… 6.00mm also achieved upon request. |

|

Material: |

Low carbon steel, low carbon galvanized steel (LCG), stainless steel (304,316 etc.) |

|

Length |

Lengths up to 6 meters. |

|

Diameter |

Ranging from 25mm to 800mm. |

|

End connection |

Plain beveled ends for butt welding or threaded |

Screen Pipe Standard:

Screen Pipe Standard:

API 5CT, API 5L, ASTM, JIS

Screen Pipe Application:

Screen Pipe Application:

Municipal water source well

Domestic well

Agricultural water well

Groundwater

Screen Pipe Tape and Advantages:

Screen Pipe Tape and Advantages:

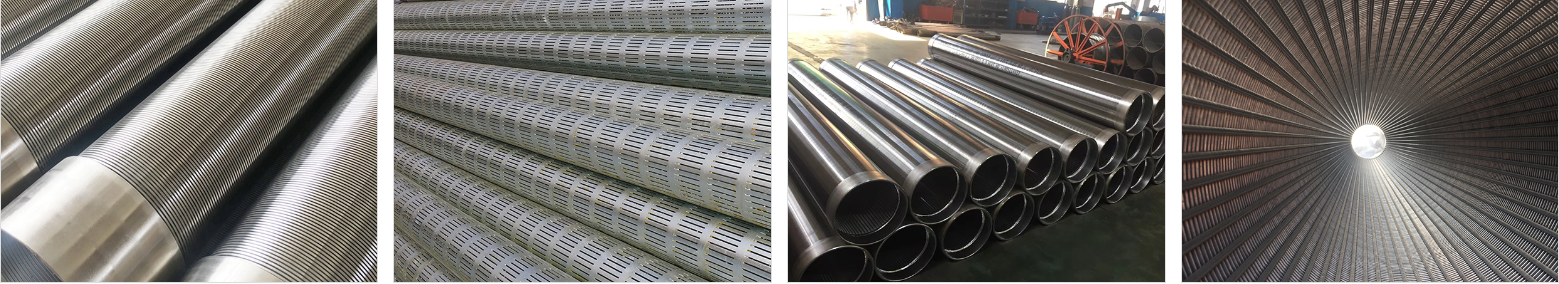

Different geological environment causes Screen Pipes with different grade and type, including Slotted Screen Pipe, Perforated Screen Pipe, Premium Mesh Sand Screens, Pre Packed Well Screen, Wire Wrapped Screen, Bridge Slotted Screen, Metal Mesh Sand Screen, etc.

Slotted Liner

The slotted liner is mainly used to the water and oil reservation layer without much sand. It’ s function is prevent rock bits dripping into the well bore. The working principle is allowing the certain size and coming through the surface with crude oil but keeping the bigger size sand stopped outside to form sand bridge, and thereby achievement the anti-sand purpose. This type of produce is commonly used to sand rock and catbonate reservoir and especially useable for horizontal wells.

Perforated pipe

Carbon steel perforated pipes manufactured with carbon steel or stainless steel.

We can drill standard or customized hole size in any number and any pattern. Every joint perforated by us is deburred internal and external. Every hole is visually inspected and cleaned of burr material.

Bridge Slotted Screen pipe

Bridge slotted screen pipe is a new product which is composed of central tube, precise punched slotted screen jacket and stainless steel ring. It has characteristics such as exquisite controlled hole. High percentage of open area, strong integral strength , resistant to deformation to corrosion and high reliability etc.

Wedge Wire Water Screen Pipe

Wedge wire water screen pipe can be made single layer or double layers. The single layer can b cut to many kinds of sieve plate. The Sieve plate mainly used for water treatment and paper making industry.

Resistant to corrosion.

Sufficient column and collapse strength.

Well prevention of sand and grit.

Suitable for different geological environment with different type screens.

Improve well productivity and efficiency.

Slotting or perforation size can be customized.

Screen Pipe Specification:

Screen Pipe Specification:

|

Wire Size |

Width(mm): 1.50 1.80 2.30 3.00 3.30 3.70 |

|

Support Rods |

Width(mm): 2.30 3.00 3.30 3.70 |

|

Note: other wires and rods available upon request |

|

|

Slot size |

0.10, 0.15, 0.20, 0.25, 0.30…… 6.00mm also achieved upon request. |

|

Material: |

Low carbon steel, low carbon galvanized steel (LCG), stainless steel (304,316 etc.) |

|

Length |

Lengths up to 6 meters. |

|

Diameter |

Ranging from 25mm to 800mm. |

|

End connection |

Plain beveled ends for butt welding or threaded |

Dimensional check- With the help of measuring instruments to verify dimensions to be within tolerance limits.

Slot opening - With feeler gauges: Slot size to be measured for all slots over 100 mm length in each metre length of screen randomly.70 percent of the slots shall fall within the tolerance and no slot shall exceed maximum deviation.

Visual checks

1. There should not be any sudden change in LD. or O.D. of screen.

2. No profile wire or support rod shall be bent on twisted.

3. No profile wire and support rod intersection shall be found without welding.

4. Welding of support rods to end rings shall be uniform with each support rod.

5. Screens shall be reasonably concentric and straight with end faces reasonably square to axis.

6. At the joining point of screen and end ring. there shall be no gap larger than slot opening

Collapse pressure - Screen sample of appro- priate length should be closed at one end by welding plain M.S. Plate. The screen outside surface to be wrapped with strong plastic film to block all slots and shall be leak proof. The sample to be bolted inside bigger pressure pipe to leave an annular space of more than 25 mm radially. Hydraulic oil to be pumped in this annular space and pressure to be built up to the specified limit of collapse strength for that size. Screen sample shall not collapse at this pressure.

Tensile strength - Screen sample of appropriate length with end rings should be closed at one end by welding strong mild steel plate and flange welded at another end for bolting. The sample is to be bolted on hydraulic cylinder such that its piston pushes against the closed end. The screen shall not break or support rod should not loosen from end ring Any other suitable method may also be used.

Weld joint strength -A small strip over one support rod to be cut from the end of the screen in push test apparatus. with the help of two metallic fingers the profile wire shall be pushed by hydraulic cylinder to separate it from support rod.It shall not separate at specified value of load as agreed to between the purchaser and the manufacturer.

The Maximum Permissible Values of Screen Tube Tolerances on Dimensions Shall Be As Given Below:

The Maximum Permissible Values of Screen Tube Tolerances on Dimensions Shall Be As Given Below:

|

Screen ID |

+ 1.5 percent |

|

|

Screen OD Screen Thickness End Ring ID |

+ 1.5 percent + 1.0 percent + 1.5 percent |

|

|

End Ring OD End Ring Thickness |

+ 1.5 percent +12.5 percent |

|

|

Screen overall length |

+ 50 mm |

|

|

Slot Opening: |

|

|

|

Slot Size |

Tolerance (70 percent of the readings) |

Max Deviation (30 percent of the readings) |

|

0.15 mm |

+ 0.05 mm |

-£ 0.10 |

|

0.20 mm |

+ 0.05 mm |

+ 0.10 |

|

0.25 mm |

+ 0.07 mm |

+ 0.15 |

|

0.50 mm |

+ 0.10 mm |

+ 0.2 |

|

0.75 mm |

+ 0.10 mm |

+ 0.2 |

|

I.00 mm |

+ 0.15 mm |

+ 0.3 |

|

1.50 mm |

+ 0.15 mm |

+ 0.3 |

|

2.00 mm |

+ 0.30 mm |

+ 0.6 |

|

3.00 mm |

+ 0.30 mm |

+ 0.6 |

Low Carbon Steel: Composition of 0.05%-0.25% carbon and up to 0.4% manganese. Also known as mild steel, it is a low-cost material that is easy to shape. While not as hard as higher-carbon steels, carburizing can increase its surface hardness.

Stainless Steel: 304 stainless steel is a T 300 Series Stainless Steel austenitic. It has a minimum of 18% chromium and 8% nickel, combined with a maximum of 0.08% carbon. It is defined as a Chromium-Nickel austenitic alloy. Grade 304 is the standard "18/8" stainless that you will probably see in your pans and cookery tools. Stainless steel 316 is generally composed of 16 to 18% chromium, 10 to 14% nickel, 2 to 3% molybdenum, and a small percentage of carbon. Adding molybdenum to stainless steel 316 increases its corrosion resistance compared to other grades of stainless steel.

HuNan Province

+86-731-85648266

LiaoNing Province

+86-731-85648266

HeBei Province

+86-731-85648299

jiangsu Province

+86-731-85648299

TianJin City

Singapore