Area

12000㎡Number of workers

Over 300 workersProduct

Stainless Steel pipe,Stainless Steel coil,Stainless Steel bar,Stainless Steel sheetFacility

Beveling Machine,Hot Induction Bend Making Extruding Machine,Heat Treatment FurnaceAnnual output

8000 tonnes for stainless pipe

Factory introduction

The annual output of the factory is 16,000 tons of stainless steel seamless pipes and 8,000 tons of stainless steel weldedpipes, with an annual output value of more than500 millionyuan. Professional production and sales of various material sand specifications of industrial stainless steel pipes, duplex stainless steel pipes, ferritic stainless steel pipes,high-temperature alloy steel pipes type enterprise. The factory attaches great importance to the continuous updating of technical equipment and the research and development of new products, and strives to meet market demand.

In order to present the best products, we use complete self-owned production equipment, skilled technicians and rich Experience,under the strict quality inspection system, implement the whole process of quality control to ensure product quality so that buyers feel at ease and users feel at ease.

Our testing equipment mainly includes: deskto spectrometer, portable spectrometer, X-ray flaw detection system, ultrasonic Detection system, eddy current detection system, large diameter steel pipe hydraulic testing machine, small diameter steel pipe hydraulic testing machine, infrared C.S analyzer, 30T universal material testing machine, Rockwell hardness tester, intergranular corrosion test device, low-magnification and high-magnification metallography Inspection and other advanced quality inspection systems to ensure that product performance meets national and international standards and meet the strict requirements of customers beg.

Products are widely used in nuclear power, aviation, petroleum,chemical industry, machinery and electric power, automobile,pharmaceutical, food, aviation fields such as aerospace andshipbuilding.The implementation standards mainly include international ISO, German DIN, European IDF,

American National 3A, Japan JIS, etc.

Stainless steel pipe is usually divided into seamless pipe and welded pipe. And in the production process, the required equipment is not the same. The difference can be seen from the two production process flow chart.

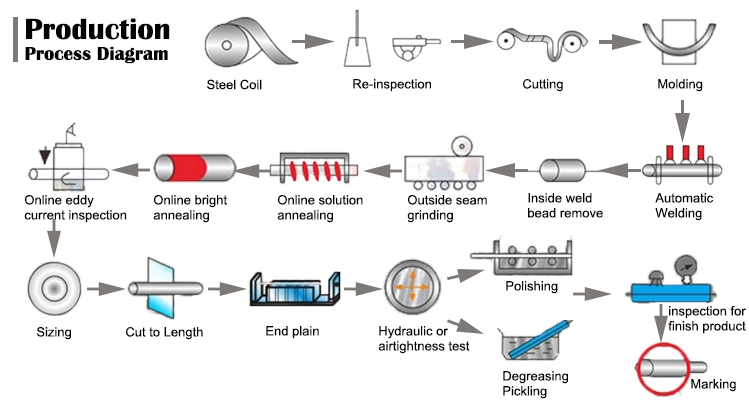

production process flow chart of stainless steel welded pipe

The above figure shows the production process flow chart of stainless steel welded pipe.The forming and welding are the

main processes for the plate (strip) to turn into a round pipe.In the welding process, the most common welding equipment

are straight seam high-frequency welding equipment, straight seam double-sided welding process and spiral submerged

arcwelding process. Mu-25m, mu-32m, mu-57m, mu-76m, mu-159m, mu-325m series automatic welded pipe units are also

common equipment in welded pipe manufacturers.

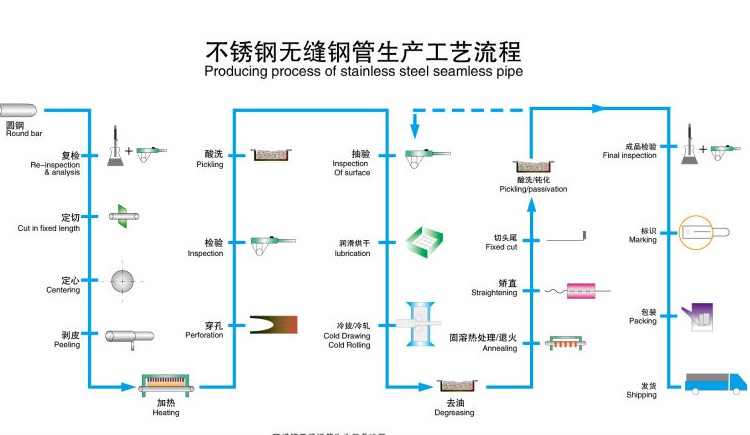

production process flow chart of stainless steel seamless pipe

The above figure shows the production process of seamless pipe.It can be seen that perforation, cold drawing (cold rolling)

and detectionare the key links in the whole process. Correspondingly, piercer,drawing mill, rolling mill and all kinds of testing

equipment play an important role in the whole production process.

USI Group has a quality inspection center to provide inspection services for the production process and finished products,Learn more about the Inspection process!