|

Product: |

galvanized pipe, galvanized steel pipe, hot dipped galvanized steel pipe,pre-galvanized steel pipe |

|

Application: |

Used for transporting low pressure liquid, gas and heating. |

|

Size: |

OD: 21.3mm ~ 406.4mm |

|

WT: 0.5mm ~ 20mm |

|

|

LENGTH: 0.3mtr ~ 18mtr, Ramdon Length, Fixed Length, SRL, DRL |

|

|

Standard |

GB/T 3091 Q195/Q215/Q235/Q345, BS 1387, EN 39, EN 1139 S235JR/S275JR, ASTM A53 GR. A/B/C, JIS G3444 STK 400/STK 500 |

|

Pipe tape |

Seamless & Welded Steel Pipe (Round/Square/Rectangular) |

Product:

galvanized pipe, galvanized steel pipe, hot dipped galvanized steel pipe,pre-galvanized steel pipe

Application:

Used for transporting low pressure liquid, gas and heating.

Size:

OD: 21.3mm ~ 406.4mm

WT: 0.5mm ~ 20mm

LENGTH: 0.3mtr ~ 18mtr, Ramdon Length, Fixed Length, SRL, DRL

Standard

GB/T 3091 Q195/Q215/Q235/Q345, BS 1387, EN 39, EN 1139 S235JR/S275JR, ASTM A53 GR. A/B/C, JIS G3444 STK 400/STK 500

Pipe tape

Seamless & Welded Steel Pipe (Round/Square/Rectangular)

End

Square Cut/Threaded, Burr Removed

Galvanized Welded Pipe Introduction

Galvanized Welded Pipe Introduction

Galvanized Welded Pipe is suitable for use in environments that require high resistance to chemical environments, marine environments or high temperatures.

Product Display & Application

Product Display & Application

specifications are as follows:

|

Standard |

ASTM A-53 |

BS 1387-1985 |

JIS G 3452 |

|

Size Range(OD) |

21.3mm to 609.6 mm |

21mm to 166 mm |

21.3 mm to 460.8 mm |

|

Thickness |

2.77mm -> 15mm |

2mm to 5.4mm |

2.8mm -> 7.9mm |

Tensile Testing

Tensile Testing

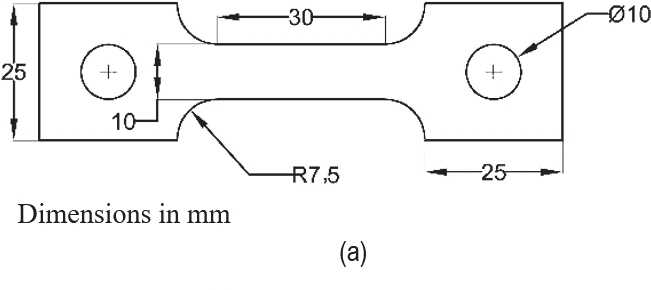

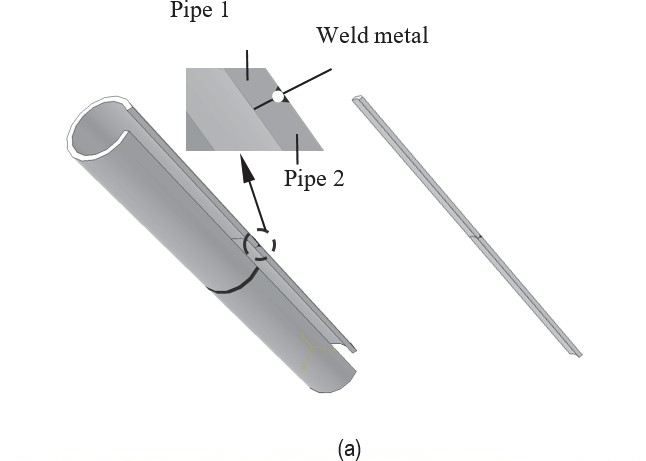

In order to measure the strength of the pipe material, a set of three sub-size tensile testing specimens were tested. The specimens were cut longitudinally of a pipe piece. Sub-size tensile specimens were chosen to account for the pipe curvature. Geometry, dimensions and orientation of the tensile specimens are shown in Fig. 1.

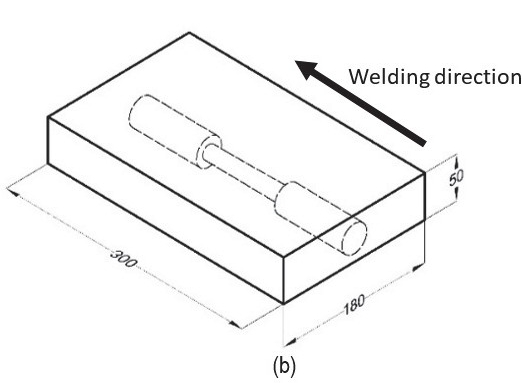

Figure 1 Sampling the tensile specimens of the tube: (a) and the specimen's geometry and dimensions and (b) specimen orientation.

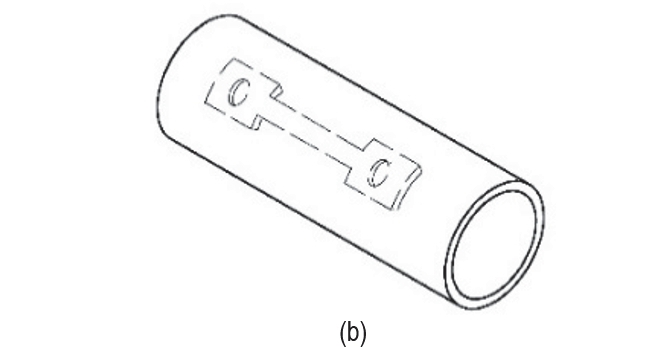

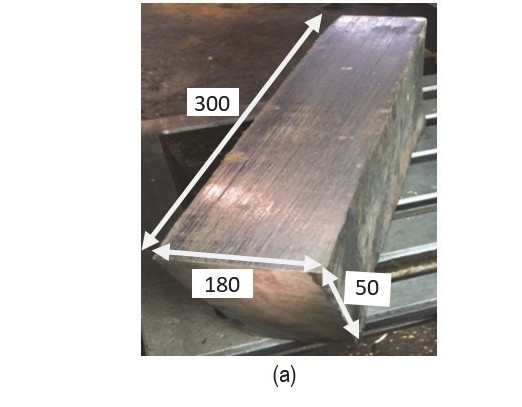

Structural integrity of welded structures depends largely on the mechanical properties of the weld metal. In order to measure the strength of the weld metal, used in the current study, a bock of weld metal was manufactured by a series welding beads deposited one above another, see Fig. 2a. Careful cleaning of the weld surface after each bead was done. The used welding electrode was designated as AWS E 6013. Standard tensile testing specimens were cut out of the weld metal block in the welding direction, see Fig. 2. Those specimens were then tested on a universal testing machine.

All the tensile testing of the pipe material and on the weld metal was carried out on a universal testing machine TM-300 with dual-column, stand-alone system with 300 kN maximum loading capacity.

Pipe Bending Testing

Pipe Bending Testing

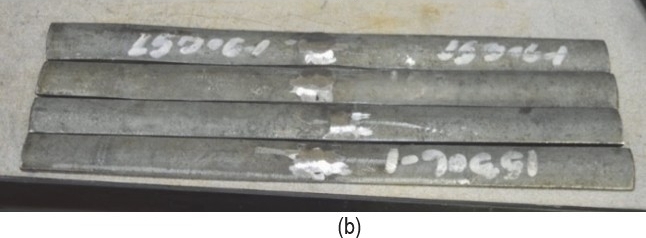

The welded pipes were subjected to bending tests. The pipes were cut longitudinally to four equal segments, as shown in Fig. 3. This is to ease the testing procedure and to characterize the difference between bending through the face and bending through the root. Fig. 4 illustrates the experimental setup for the three-point bending tests. Geometry and dimensions of the pipe specimens along with the bending test layout are shown in Fig. 5. The face- bending test was performed such that the weld face was on the outside of the bend radius. The root-bending test was performed such that the weld root was on the outside of the bend radius.

Figure 2 Sampling the tensile specimen of the weld metal. (a) In-house made block of weld metal. (b) Sampling the specimen out of the weld metal block. (Dimensions in mm)

Figure 3 Sampling of bending specimen of the welded pipes

ASTMA53/A53M-07 American Society for Testing and Materials:

ASTMA53/A53M-07 American Society for Testing and Materials:

|

Standard |

Chemical Composition |

Mechanical Properties |

||||||

|

|

C |

Si |

Mn |

P |

S |

Yield Strength |

Tensile Strength |

Elongation 2in (50mm) |

|

|

Max% |

Max% |

Max% |

Max% |

Max% |

(Min) |

(Min) |

(Min) |

|

Grade A |

0.25 |

- |

0.95 |

0.05 |

0.045 |

205 |

330 |

- |

|

Grade B |

0.30 |

- |

1.20 |

0.05 |

0.045 |

240 |

415 |

- |

StandardJIS G 3452-2004 Japanese Industrial Standard Specifies:

StandardJIS G 3452-2004 Japanese Industrial Standard Specifies:

|

Standard |

Chemical Composition |

Mechanical Properties |

|||||

|

|

C Max% |

Mn Max% |

P Max% |

S Max% |

Yield Strength MPa |

Tensile Strength MPa |

Elongation

Min |

|

SGP |

- |

- |

0.040 |

0.040 |

- |

290 |

30 |

EN 10255:2004 (BS 1387-1985) British Standard:

EN 10255:2004 (BS 1387-1985) British Standard:

|

Standard |

Chemical Composition |

Mechanical Properties |

Hydrostatic Test (Bar) |

|||||

|

|

C Max% |

Mn Max% |

P Max% |

S Max% |

Yield Strength (Min) |

Tensile Strength (Min) |

Elongation (Min) |

|

|

Class Light |

0.20 |

1.40 |

0.035 |

0.030 |

195 |

320-520 |

20 |

50 |

|

Class Medium |

0.20 |

1.40 |

0.035 |

0.030 |

195 |

320-520 |

20 |

50 |

|

Class Heavy |

0.20 |

1.40 |

0.035 |

0.030 |

195 |

320-520 |

20 |

50 |

HuNan Province

+86-731-85648266

LiaoNing Province

+86-731-85648266

HeBei Province

+86-731-85648299

jiangsu Province

+86-731-85648299

TianJin City

Singapore