Product Name:Drill Collars ,Spiral Drill Collar,Non-magnetic Drill Collar,Drill Collar and Drill Stem Accessories;

Size:Outer diameter:3 1/8"-11"

Length:30Ft / 31Ft / 43Ft/R1~R3

Connection type:NC , REG , FH, IF

Thread:NC26, NC31, NC38, NC40, NC46, NC50, 5.1/2FH

Material:Stainless Steel/Alloy steel/4145H/Carbon steel

Standard:API 5DP/API Spec 7-1

Application:Oil and gas well drilling/Oilfield Drilling

Product Name:Drill Collars ,Spiral Drill Collar,Non-magnetic Drill Collar,Drill Collar and Drill Stem Accessories;

Size:Outer diameter:3 1/8"-11"

Length:30Ft / 31Ft / 43Ft/R1~R3

Connection type:NC , REG , FH, IF

Thread:NC26, NC31, NC38, NC40, NC46, NC50, 5.1/2FH

Material:Stainless Steel/Alloy steel/4145H/Carbon steel

Standard:API 5DP/API Spec 7-1

Application:Oil and gas well drilling/Oilfield Drilling

Classification

Classification

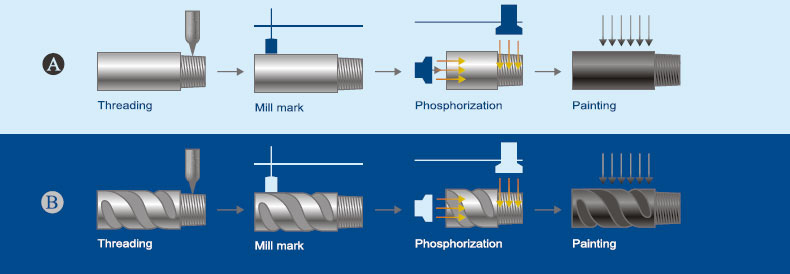

1) Slick Drill Collar

Drill Collar is an integral heavy-wall joint manufactured from a solid bar of modified alloy steel. The solid bar is quenched and tempered to obtain required mechanical properties, then trepanned, drifted and threaded. Drill collar is furnished as slick or spiraled in 30 or 31 foot lengths.

Slick drill collar is supplied with the mill as-rolled surface finish. Spiraled drill collar has grooves machined in its outside surface. The spiral grooves promote even flow of drilling fluid around collar diameter, equalizing pressure and reducing the occurrence of differential sticking.

2) Spiral Drill Collar

Spiral drill collar is used to reduce contact area with hole so as to avoid efficiently bit sticking from differential pressure. Our spiral drill collars are manufactured strictly according to API standard.

a. Materials: AISI 4145H alloy steel, non magnetic steel, etc.

b. Shape: It is a kind of drill collar which adds three dextrogyrate spiral grooves on the outer circle of ordinary drill collar when processing, to reduce the area of contact and friction with well wall, which can effectively prevent pressure sticking.

c. Usage: It is mainly used between drill head and drill pipe, so that it can make drill head work reposefully and keep right trace by providing the pressure and weight for drill head.

d. Standard: API Spec 7-1 or SY/T5144 Standard.

e. Inspection & Test: In the process of production, traceability are maintained from the receipt of raw material to the completion of final products, and serial numbers are die stamped on each work piece body. Inspection and test are performed in every manufacturing process.

3) Non-magnetic Drill Collar

The materials of non-magnetic drill collars are made from chrome manganese low carbon austenitic alloy, which has the following characteristics:

The chemical composition should be controlled strictly in the refining and forging process.

With excellent lower magnetic permeability, high strength of mechanical properties and outstanding resistant to stress corrosion cracking, and no tendency to galling.

Slip and Elevator Recess Dimensions

Slip and Elevator Recess Dimensions

|

Drill Collar Diameter (in.) |

Elevator Recess Diameter (in.) |

Slip Recess Diameter (in.) |

Elevator Recess Radius (in.) |

|

4⅛ |

311/16 |

3¾ |

⅛ |

|

4¾ |

4¼ |

4⅜ |

⅛ |

|

5 |

4½ |

4⅝ |

⅛ |

|

6 |

5⅜ |

5½ |

⅛ |

|

6¼ |

5⅝ |

5¾ |

⅛ |

|

6½ |

5⅞ |

6 |

⅛ |

|

6¾ |

6 |

6¼ |

3/16 |

|

7 |

6¼ |

6½ |

3/16 |

|

7¼ |

6½ |

6¾ |

3/16 |

|

7¾ |

7 |

7¼ |

3/16 |

|

8 |

7¼ |

7½ |

3/16 |

|

8¼ |

7½ |

7¾ |

3/16 |

|

9 |

8⅛ |

8¼ |

¼ |

|

9½ |

8⅝ |

9 |

¼ |

|

9¾ |

8⅞ |

9¼ |

¼ |

|

10 |

9⅛ |

9½ |

¼ |

|

11 |

10⅛ |

10½ |

¼ |

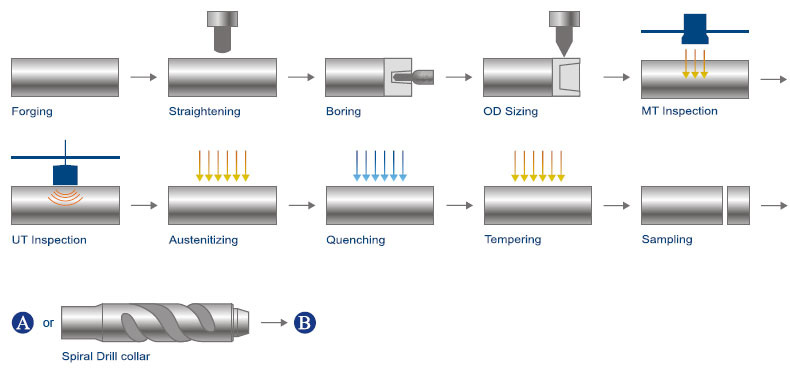

Drill Collar Production Process

Drill Collar Production Process

Drill Collar Material Mechanical Properties

Drill Collar Material Mechanical Properties

|

Drill Collar Material Mechanical Properties |

|||

|

Drill Collar Diameter (in.) |

Minimum Yield Strength (psi) |

Minimum Tensile Strength (psi) |

Minimum Hardness (BHN) |

|

3⅛ through 6⅞ |

110,000 |

140,000 |

285 |

|

7 and above |

100,000 |

135,000 |

285 |

HuNan Province

+86-731-85648266

LiaoNing Province

+86-731-85648266

HeBei Province

+86-731-85648299

jiangsu Province

+86-731-85648299

TianJin City

Singapore