| Application: | Widely used in furniture,interior decoration, structure |

| Size: | OD: 20mm*10mm ~ 400mm*300mm |

| Pipe Standard: | ASTM A53, ASTM A500,BS EN 10219,JIS G 3466, ASTM A513, ASTM A36 |

| S235JR,S355JR,Q235,St37,St37-2,St52,SS400, STK500,Q235B, Q345 | |

| Furface: | Black bared ,can be galvanized,oiled,painted,powdered. |

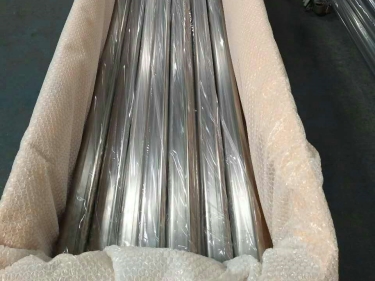

| Packing: |

Waterproof plastic bag,bundle with strip |

Application:

Widely used in furniture,interior decoration, structure

Size:

OD: 20mm*10mm ~ 400mm*300mm

Pipe Standard:

ASTM A53, ASTM A500,BS EN 10219,JIS G 3466, ASTM A513, ASTM A36

S235JR,S355JR,Q235,St37,St37-2,St52,SS400, STK500,Q235B, Q345

Furface:

Black bared ,can be galvanized,oiled,painted,powdered.

Packing:

Waterproof plastic bag,bundle with strip

Application:

Widely used in furniture,interior decoration, structure

Size:

OD: 20mm*10mm ~ 400mm*300mm

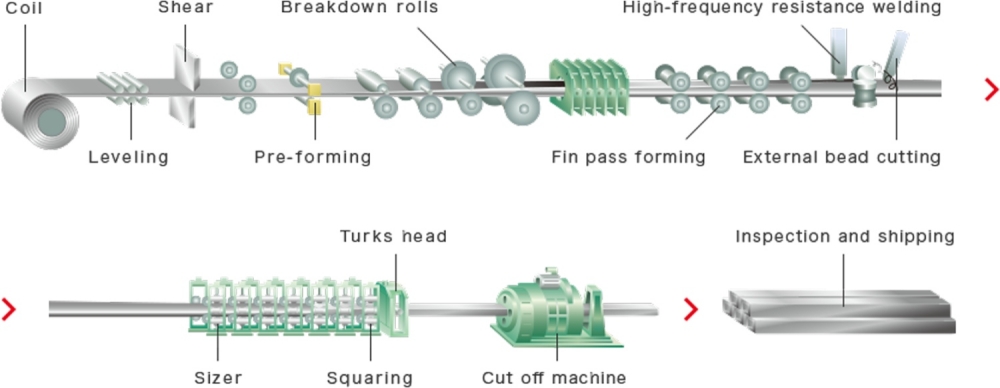

Rectangular Steel Tube Introduction

Rectangular Steel Tube Introduction

Rectangular Steel Tube Mechanical Properties of Material

Rectangular Steel Tube Mechanical Properties of Material

|

Grade |

Yield Strength |

Tensile Strength |

Elongation |

|

A500.Gr.b |

46 ksi |

58 ksi |

23% |

|

A513.GR.B |

72 ksi |

87 ksi |

10% |

|

Norm |

Yield Strength |

Tensile Strength |

Min.elogation |

Min.percent properties |

||||||||

|

Acc.to EN10027/1 and IC 10

|

Acc.to EN10027/2 |

Norminal W.T.mm |

Norminal W.T.mm |

Longit. |

Cross |

Test temperature°C |

Average min.impact value |

|||||

|

≤16 |

>6 |

>40 |

<3 |

≤3≤65 |

Norminal W.T.mm |

|||||||

|

≤65 |

≤65 |

≤40 |

>40 |

>40 |

≤65 |

|||||||

|

≤65 |

≤40 |

|||||||||||

|

S253JRH |

1.0039 |

235 |

225 |

215 |

360-510 |

340-470 |

26 |

25 |

24 |

23 |

20 |

27 |

|

S275JOH |

1.0149 |

275 |

265 |

255 |

410-580 |

410-560 |

22 |

21 |

20 |

19 |

0 |

27 |

|

S275J2H |

1.0138 |

275 |

265 |

255 |

430-560 |

410-560 |

22 |

21 |

20 |

19 |

-20 |

27 |

|

S355JOH |

1.0547 |

355 |

345 |

335 |

510-680 |

490-630 |

22 |

21 |

20 |

19 |

0 |

27 |

|

S355J2H |

1.0576 |

355 |

345 |

335 |

510-680 |

490-630 |

22 |

21 |

20 |

19 |

-20 |

27 |

Equivalent Specification of Rect Tubing

Equivalent Specification of Rect Tubing

|

EN 10210-1 |

NF A 49501 NF A 35501 |

DIN 17100 DIN 17123/4/5 |

BS 4360 |

UNI 7806 |

|

S235JRH |

E 24-2 |

St 37.2 |

– |

Fe 360 B |

|

S275JOH |

E 28-3 |

St 44.3 U |

43 C |

Fe 430 C |

|

S275J2H |

E 28-4 |

St 44.3 N |

43 D |

Fe 430 D |

|

S355JOH |

E 36-3 |

St 52.3 U |

50 C |

Fe 510 C |

|

S355J2H |

E 36-4 |

St 52.3 N |

50 D |

Fe 510 D |

|

S275NH |

– |

St E 285 N |

– |

– |

|

S275NLH |

– |

TSt E 285 N |

43 EE |

– |

|

S355NH |

E 355 R |

St E 355 N |

– |

– |

|

S355NLH |

– |

TSt E 355 N |

50 EE |

– |

|

S460NH |

E 460 R |

St E 460 N |

– |

– |

|

S460NLH |

– |

TSt E 460 N |

55 EE |

– |

– block letter "S" means "STEEL FOR STRUCTURAL APPLICATIONS"

– the next fi gure means the minim. yield value required for wall thickness ≤16 mm

– "J2" means impact test value -20° C min. 27 joule

– block letter "H" means "HOLLOW SECTION".

Mechanical Tests:

Mechanical Tests:

The following tests shall be carried out on the selected tube, strip or plate. For mechanical tests, tubes shall be sampled in accordance with IS 4711.

Tensile Test:

The tensile strength, the yield stress and the percentage elongation shall be determined in accordance with the methods specified in IS 1608 and shall be not less than the values specified for the relevant grades of tubes given in the table below.

The tensile test shall be made on:

a length cut from the end of the selected tube (the ends of the length being plugged for grips, where necessary); or

a longitudinal strip cut from the tube, not including the weld, if any, and tested in the curved condition, the choice resting with the manufacturer.

Ductility Test:

Ductility Test:

Cold Bend Test (Up to and Including 50 mm NB): When tested in accordance with IS 2329 an unfilled length of tube shall be capable of being bent cold by tube bending machine around a grooved former (with radius at bottom of the groove equal to 6 x O.D. of the tube) through 180’(with weld at 90’to the plane of bending) without showing any crack at the weld or the metal.

Flattening Test (Tubes above 5Omm NB): Rings, not less than 40 mm in length cut from the ends of selected tubes with edges rounded shall be flattened between parallel plates with the weld, if any, at 90’(point of maximum bending) in accordance with IS 2328. No opening shall occur by fracture in the weld until the distance between the plates is less than the value specified for each grade in co1 4 of the table given below and no cracks or breaks in the metal elsewhere than in the weld shall occur until the distance between the plates is less than the value specified for each grade in col5 of the table given below.

Retest:

Retest:

Should any one of the test pieces first selected fail to pass any of the tests specified, two further samples shall be selected for testing in respect of each failure from the same lot. Should the test pieces from both these additional samples pass, the material represented by the test samples shall be deemed to comply with the requirement of that particular test. Should the test pieces from either of these additional samples fail, the material represented by the test samples shall be deemed as not complying with the standard or the manufacturer may select to test individually the remaining lengths in the lot for the test failed to comply in the preceding tests.

Rectangular Steel Tube Tolerances:

Rectangular Steel Tube Tolerances:

|

Largest Outside Dimension Across Flats |

Tolerance (+/-) inches* |

|

2-1/2 and under |

0.020 |

|

Over 2-1/2 to 3-1/2 incl |

0.025 |

|

Over 3-1/2 to 5-1/2 incl |

0.030 |

|

Over 5-1/2 |

1% |

* Tolerances include allowance for convexity or concavity. Tolerance may be increased 50% when applied to the smaller dimension of rectangular sections whose ratio if the cross-sectional dimensions is between 1.5 and 3, and 100 percent when the ratio exceeds 3.

WALL THICKNESS TOLERANCE

WALL THICKNESS TOLERANCE

The tolerance for wall thickness exclusive of weld area shall be plus or minus 10% of the nominal wall thickness specified. The wall thickness is to be measured at the center of the flat.

STRAIGHTNESS TOLERANCE

STRAIGHTNESS TOLERANCE

The permissible variation for straightness shall be 1/8" times the number of feet of the total length divided by 5.

SQUARENESS OF SIDES

SQUARENESS OF SIDES

Adjacent sides may deviate from 90° by a tolerance of plus or minus 2° maximum.

RADIUS OF CORNERS

RADIUS OF CORNERS

The radius of the outside corner of the section shall not exceed three times the specified wall athickness.

TWIST TOLERANCES

TWIST TOLERANCES

Twist is measured by holding down one end of square or rectangular tube on a flat surface plate with the bottom side of the tube parallel to the surface plate and noting the height that either corner, at the opposite end of the bottom side of the tube, extends above the surface plate.

|

Specified Dimension of Longest Side |

Maximum Twist (inches) in 3 feet |

|

1-1/2 and Under |

0.050" |

|

Over 1-1/2 to 2-1/2 incl |

0.062" |

|

Over 2-1/2 to 4 incl |

0.075" |

|

Over 4 to 6 incl |

0.087" |

|

Over 6 to 8 incl |

0.100" |

|

Over 8 |

0.112" |

|

Grade |

Element |

C |

Mn |

P |

S |

|

ASTM A500 Gr.b |

% |

0.05%-0.23% |

0.3%-0.6% |

0.04% |

0.04% |

|

Acc.to EN10027/1 |

Acc.to EN10027/2 |

C% max (Norminal W.T.(mm) |

Si% max |

Mn% max |

P% max |

S% max |

N% max |

|

|

and IC 10 |

|

≤ 40 |

|

|||||

|

S235JRH |

1.0039 |

0.17 |

0.20 |

- |

1.40 |

0.045 |

0.045 |

0.009 |

|

S275JOH |

1.0149 |

0.20 |

0.22 |

- |

1.50 |

0.040 |

0.040 |

0.009 |

|

S275J2H |

1.0138 |

0.20 |

0.22 |

- |

1.50 |

0.035 |

0.035 |

- |

|

S355JOH |

1.0547 |

0.22 |

0.22 |

0.55 |

1.60 |

0.040 |

0.040 |

0.009 |

|

S355J2H |

1.0576 |

0.22 |

0.22 |

0.55 |

1.60 |

0.035 |

0.035 |

- |

HuNan Province

+86-731-85648266

LiaoNing Province

+86-731-85648266

HeBei Province

+86-731-85648299

jiangsu Province

+86-731-85648299

TianJin City

Singapore