|

Scope |

Steel pipe piling for permanent, structural load-carrying member or as a shell to form cast-in-place concrete piles. |

|

Specification |

ASTM A252, Grades 2 and 3/modified to 50 ksi min. yield |

|

Manufacturing Process |

Straight-seam electric resistance weld (ERW) |

|

Size (OD) |

8.625, 10.750 and 12.750 |

|

Gauge/Wall Thickness |

0.250, 0.313, 0.375 and 0.500 (nominal) |

|

Strength/Elongation Properties |

Yield: 50 ksi min., 60 ksi min., 75 ksi min., 80 ksi min. Aim to. Tensile: 66 ksi min. Elongation: 20% min. |

|

Straightness Tolerance |

1/8” x length (in feet), divided by five |

Piling Steel Pipe Specification

Piling Steel Pipe Specification

|

Scope |

Steel pipe piling for permanent, structural load-carrying member or as a shell to form cast-in-place concrete piles. |

|

Specification |

ASTM A252, Grades 2 and 3/modified to 50 ksi min. yield |

|

Manufacturing Process |

Straight-seam electric resistance weld (ERW) |

|

Size (OD) |

8.625, 10.750 and 12.750 |

|

Gauge/Wall Thickness |

0.250, 0.313, 0.375 and 0.500 (nominal) |

|

Strength/Elongation Properties |

Yield: 50 ksi min., 60 ksi min., 75 ksi min., 80 ksi min. Aim to. Tensile: 66 ksi min. Elongation: 20% min. |

|

Straightness Tolerance |

1/8” x length (in feet), divided by five |

|

Weight Tolerance |

Weight must not vary more than 15% over or 5% under. Piling weight controlled by utilizing minimum-gauge coil stock. Searing does not weigh each individual length of pipe. |

|

Chemical Composition |

Carbon: 0.23 max. Manganese: 1.35 max. Meets ASTM A252 |

|

Carbon Equivalent (CE) |

0.45 max (per AWS D1.1) |

|

Weldability |

AWD D1.1 base metal Can be welded with AWS prequalified welding procedures |

|

Testing |

ASTM A370: In-house flattening and cone test per heat |

|

Material Test Reports |

Material test reports are furnished for each length of pipe. Steel mill coil certifications/gauge certifications available upon request. |

|

Marking/ID Stamp |

Ink stenciling on one side of the OD, ID stamping when requested |

|

STRENGTH LEVELS |

GRADE 2 |

GRADE 3 |

|

Yield Strength |

35,000 psi min. |

45,000 psi min. |

|

Tensile Strength |

60,000 psi min. |

66,000 psi min. |

|

Elongation % in 2” Min. |

25 |

20 |

|

Meets AWS D1.1 Base Metal Welding requirements |

Yes |

Yes |

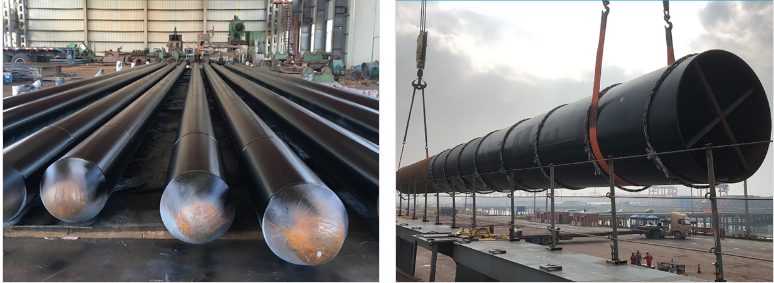

Piling Steel Pipe Image

Piling Steel Pipe Image

Advantages of Pipe Piles

Advantages of Pipe Piles

As opposed to other options for deep foundations, pipe piles offer several advantages.

1. They lower costs because they are capable of being tailored to meet specific load bearing requirements.

2. They are simple to drive and install, and they’re easy to inspect and test before use.

3. They are sturdy and unlikely to crack or otherwise get damaged while they are being driven into the ground.

4. Additionally, pipe piles can be added to bolster foundation support after construction and during various phases of construction.

Application of Steel Pipe Pill

Application of Steel Pipe Pill

Pipe piles can be used for the creation of the following:

• Building foundations

• Bridge foundations

• Highway foundations

• Marine structure foundations

• Dock foundations

• Offshore construction foundations

• Railway foundations

• Oilfield construction foundations

• Communication tower foundations

• Column foundations

Types of Piling Steel Pipes

Types of Piling Steel Pipes

Based on the different soil environments and requirements, Pipe piling could be divided in open end pile (Unplugged pipe pile) and close end pile pipe(Plugged pipe pile).

As soon as we receive your pipe pile designs, our fabrication division will begin creating your pipe piling. Fabrication is usually carried out in these steps:

Cut out and etch steel plate with CNC plasma cutters.

Bevel the plate ends (if required) to ensure quality welding.

Roll the plate into cylinders.

Weld the longitudinal seam of the cylinder.

Connect cylinders by welding the circumferential seam using our sophisticated submerged arc process.

Forward the pipe pile to T BAILEY INC.’s testing division, where the completed pipe piling must pass rigorous inspection before shipment to the job site.

If project specifies, the steel is blasted and coated to increase longevity.

Our Testing Capabilities Include:

Our Testing Capabilities Include:

Visual inspection and step by step monitoring of all processes to ensure the best possible quality

Radiographic Testing (RT)

Ultrasonic Testing (UT)

Dye Penetrant Testing (PT)

Magnetic Particle Testing (MT)

Heat treating and stress relieving

Hardness Testing

Impact Testing

Positive Material Identification (PMI)

Leak Testing

Hydrostatic Testing, up to 2,500 psig

Environmental monitoring and reporting

Soluble Salt Testing

Full blast and lining profile measuring

Dry film thickness testing

Adhesion Testing

Lining continuity (holiday) testing

Piling Steel Pipe Weight and Dimension Tolerances

Piling Steel Pipe Weight and Dimension Tolerances

Pipe pile weights per units (Feet, meter or lengths)

Tolerance allowed: A252 pipe pile weight shall be in +15% or -5% of theoretic weight. OD tolerances at +/-1%, wall thickness +/- 12%.

Lengths: As specified SRL, DRL, or fixed length 20 ft or 40 ft and customized.

Permissible Variations for A252 Piling Steel Pipe

Permissible Variations for A252 Piling Steel Pipe

Wall thickness: Not more than 12.5% under the nominal wall thickness specified.

Weights per foot: The weight of any individual length of pipe shall not vary more than 15% over or 5% under the weight specified. Each individual length shall be weighed separately.

Outside diameter: Shall not vary more than plus or minus 1% from the diameter specified.

|

TOLERANCES |

ALL GRADES |

|

OD Size |

|

|

>1.9 - 2.5 incl. |

+/- 1% |

|

>2.5 - 3.5 incl. |

+/- 1% |

|

>3.5 - 5.5 incl. |

+/- 1% |

|

>5.5 |

+/- 1% |

|

Wall Thickness |

–12.5% |

|

Weight |

+15% / –5% |

|

Straightness (max. allowed) |

Not specified |

Chemical Requirements for A252 Steel Pipe

Chemical Requirements for A252 Steel Pipe

|

|

Phosphorus |

|

Seamless and ERW Welded |

Max% 0.050 |

|

Chemical Composition |

Carbon: 0.23 max. Manganese: 1.35 max. Meets ASTM A252 |

|||

|

CHEMISTRY LEVELS |

ALL GRADES |

|||

|

Carbon |

N/A |

|||

|

Manganese |

N/A |

|||

|

Phosphorus |

0.050 max. |

|||

|

Sulphur |

N/A |

|||

|

Silicon |

N/A |

|||

|

Grain Refining Elements |

N/A |

|||

HuNan Province

+86-731-85648266

LiaoNing Province

+86-731-85648266

HeBei Province

+86-731-85648299

jiangsu Province

+86-731-85648299

TianJin City

Singapore