| Tee Type | Equal/Unequal Tee, Cross Tee, Socket Tee, Short Tee, Forging Tee |

| Material | Carbon Steel --- ASTM A234 WPB/WPC, ANSI B 16.9, ASTM A105/A106/A53, |

| API 5L GR.B/A671-CC-70/A515-50/A135-A/A179-C | |

| Stainless Steel --- ASTM 403 304/304L,316/316L,316Ti,321,317L,310S | |

| Alloy Steel --- ASTM A234 WP1/5/9/11/12/22/91 | |

| Specification | NPS from 1/2'' to 36'', DN from 15 to 900 |

| WT: 2-80mm, SCH 40/80/XXS | |

| Surface | Light Oiling, Black Painting |

| Packing | Packed in Wood Cabins/ Wood Tray |

Tee Type

Equal/Unequal Tee, Cross Tee, Socket Tee, Short Tee, Forging Tee

Material

Carbon Steel --- ASTM A234 WPB/WPC, ANSI B 16.9, ASTM A105/A106/A53,

API 5L GR.B/A671-CC-70/A515-50/A135-A/A179-C

Stainless Steel --- ASTM 403 304/304L,316/316L,316Ti,321,317L,310S

Alloy Steel --- ASTM A234 WP1/5/9/11/12/22/91

Specification

NPS from 1/2'' to 36'', DN from 15 to 900,

WT 2-80mm, SCH 40/80/XXS

Surface

Light Oiling, Black Painting

Packing

Packed in Wood Cabins/ Wood Tray

pipe fitting tee Introduction

pipe fitting tee Introduction

Types of Pipe Tees:

Types of Pipe Tees:

According to the type of end connections, tees are classified as follows: socket welded tee, threaded tee, butt welding tee, flanged tee.

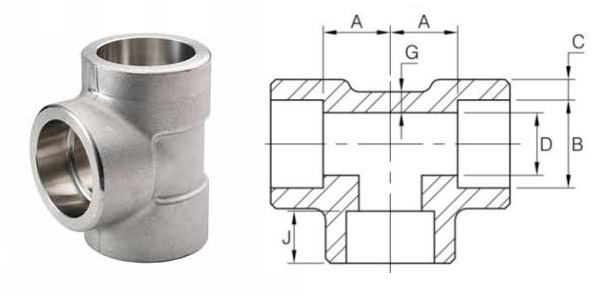

Socket Welded Tee:

socket-weld-pipe-tee

These tees are usually forged and used up to 2″ run size on services for socket welded connections,the standard of socket weld steel tees is ASME B16.11,the material standards including rating are same as the requirements of other socket welded pipe fittings.

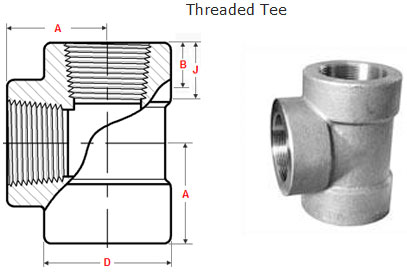

Threaded Tee:

threaded-pipe-tee

The threaded tees are in same standard ASME B16.11,the ends is thread type,other dimensions,rating and materials are same as socket welded tees.

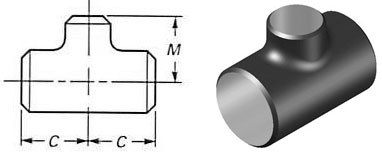

Butt Welding Pipe Tee:

butt-weld-pipe-tee

The dimensional standard for the butt welding pipe tees is ASME/ANSI B16.9, these are available from 1/2″ through 48″,including the equal tee and reducing tee.

Reducing tees are available having branches up to one size lower than half run pipe size.For example,if run size is 6″,reducing tees are available in sizes 6″x5″, 6″×4″,6″×3″&6″× 2 1/2″.

Applicable Pressure temperature rating and material standards are same as those for other butt welding pipe fittings.Butt welding tees are usually used for size 1/2″ to 48″.

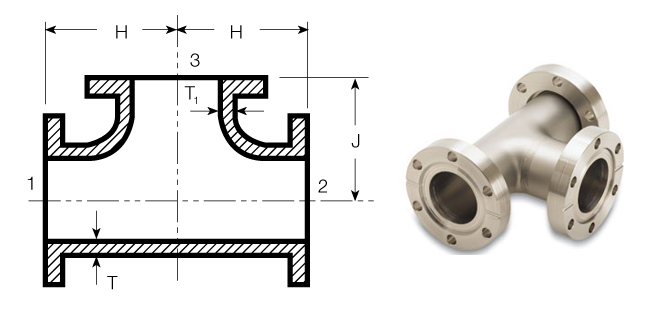

Flanged Pipe Tee:

flanged-pipe-tee

These tees are used in the flanged end connections in normal large bore pressure piping.Commonly it is a butt welding pipe tee with three flanges welded.The ASME B 31.3 (Appendix D) provides formula for calculating information for reference.

Features of Pipe Tees:

Features of Pipe Tees:

There are three female openings in a T shaped pipe tee.

There are straight pipe tees which have the same size openings.

Reducing pipe tees have one opening of different size and two openings of the same size.

There are sanitary pipe tees which are used in waste lines. These kind of pipe tees have a curved branch which is designed for a clean out plug. They are used to prevent obstruction of waste.

A cross pipe tee has four equal sized female openings.

A wing pipe tee has lugs to fasten the fitting to a wall or stud.

A compression pipe tee uses compression fittings on two or more ends.

A test pipe tee has a threaded opening. This opening is used in conjunction with a threaded plug for a clean-out opening on a drain pipe.

Applications of Pipe Tees:

Applications of Pipe Tees:

Pipe Tees are widely used in various commercial and industrial applications. Industrial applications include:

Chemical processing

Petroleum

Pulp/paper

Refining

Textile

Waste treatment

Marine

Utilities/power generation

Industrial equipment

Automotive

Gas compression and distribution industries

Pipe Tees are also recommended for industrial plant fluid power systems.

|

Standard |

Specification |

|

ASTM A234 |

Standard Specification for Piping Fittings of Wrought Carbon Steel and Alloy Steel for Moderate and High Temperature Service |

|

ASTM A420 |

Standard Specification for Piping Fittings of Wrought Carbon Steel and Alloy Steel for Low-Temperature Service |

|

ASTM A234 WPB |

ASTM A234 is Standard Specification for steel pipe fittings includes carbon and alloy steel material for moderate and high temperature services. WPB is one of the steel grade in this standard |

|

ASME B16.9 |

ASME B16.9 Standard covers overall dimensions, tolerances,ratings, testing, and markings for factory-made wrought buttwelding fittings in sizes NPS 1⁄2 through NPS 48 (DN 15 through DN 1200). |

|

ASME B16.28 |

ASME B16.28 Standard covers ratings, overall dimensions, testing, tolerances, and markings for wrought carbon and alloy steel buttwelding short radius elbows and returns. |

|

MSS SP-97 |

MSS SP-97 Standard Practice covers essential dimensions, finish, tolerances, testing, marking, material, and minimum strength requirements for 90 degree integrally reinforced forged branch outlet fittings of buttwelding, socket welding, and threaded types. |

|

ASTM A403 |

Standard Specification for Wrought Austenitic Stainless Steel Piping Fittings. |

Hydrotest Test

Hydrotest Test

Hydrostatic Test Not required for pipe fittings unless specifically requested by the purchaser.

Code mandates that fittings be able to withstand the pressure required by the applicable Piping Code.

Most purchasers mandate that a hydro-tested pipe shall be used to manufacture fittings.

Proof Test

Proof Test

To qualify the design of the pipe fitting, the manufacturer performed various tests, including a burst test, to ensure that the design would meet all the standard & code requirements. In this test, a pipe & fittings are welded, and a dummy pipe spool is prepared.

This pipe spool is then pressurized to pre-define calculated burst test pressure. If the fittings withstand the test, all future products manufactured using that design will consider safe to use.

Lap joint stub ends are exempt from the proof test because they are used with flange assembly and design considering applicable pressure-temperature ratings.

Non-Destructive Testing

Non-Destructive Testing

Based on the type of fittings, any of the following Non-Destructive testings are performed on finished fittings to ensure the soundness of the product.

Ultrasonic

Radiography (Only for Weld)

Magnetic particle test

Liquid penetrant test

And Positive Material Identification

Destructive Testing

Destructive Testing

Destructive Testings are performed to check the strength of the body and weld of the product.

The proof test is also known as a Type Test or burst test.

Tensile test

Impact test / Charpy V-Notch Test

Hardness test

Metallurgical Tests

Metallurgical Tests

Metallurgical Tests are performed on fittings body and weld to confirm standard requirements.

Micro Analysis or Chemical Analysis of

Raw material

Product

Weld

Macro Analysis

Weld

Special Tests

Special Tests

Special tests are carried out on fittings to confirm their ability to withstand corrosive environments. These tests are

IGC- Intergranular Corrosion Test(SS)

Ferrite (SS)

HIC- Hydrogen-induced Cracking

And SSC- Sulfide Stress Corrosion Cracking

Grain size (AS & SS) of material are checked to confirm microstructure

|

NOMINAL PIPE SIZE NPS |

ANGULARITY TOLERANCES |

ANGULARITY TOLERANCES |

|

Size |

Off Angle Q |

Off Plane P |

|

½ to 4 |

0.03 |

0.06 |

|

5 to 8 |

0.06 |

0.12 |

|

10 to 12 |

0.09 |

0.19 |

|

14 to 16 |

0.09 |

0.25 |

|

18 to 24 |

0.12 |

0.38 |

|

26 to 30 |

0.19 |

0.38 |

|

32 to 42 |

0.19 |

0.5 |

|

44 to 48 |

0.18 |

0.75 |

All dimensions are given in inches. Tolerances are equal plus and minus except as noted.

Out-of-round is the sum of absolute values of plus and minus tolerance.

This tolerance may not apply in localized areas of formed fittings where increased wall thickness is required to meet design requirements of ASME B16.9.

The inside diameter and the nominal wall thicknesses at ends are to be specified by the purchaser.

Unless otherwise specified by the purchaser, these tolerances apply to the nominal inside diameter, which equals the difference between the nominal outside diameter and twice the nominal wall thickness.

Chemical Composition (%) of ASTM A234/A234M

Chemical Composition (%) of ASTM A234/A234M

|

Grade |

Type |

C |

Si |

S |

P |

Mn |

Cr |

Ni |

Mo |

Other |

ób |

ós |

δ5 |

|

WPB |

0.3 |

0.1min |

0.058 |

0.05 |

0.29-1.06 |

0.4 |

0.4 |

0.15 |

V:0.06;Nb:0.02 |

415-585 |

240 |

22 |

197 |

|

WPC |

0.35 |

0.1min |

0.058 |

0.05 |

0.29-1.06 |

0.4 |

0.4 |

0.15 |

V:0.06;Nb:0.02 |

485-655 |

275 |

22 |

197 |

|

WP1 |

0.28 |

0.1-0.5 |

0.045 |

0.045 |

0.3-0.9 |

|

|

0.44-0.65 |

|

380-550 |

205 |

22 |

197 |

|

WP12 CL1 |

0.05-0.2 |

0.6 |

0.045 |

0.045 |

0.3-0.8 |

0.8-1.25 |

|

0.44-0.65 |

|

415-585 |

220 |

22 |

197 |

|

WP12 CL2 |

0.05-0.2 |

0.6 |

0.045 |

0.045 |

0.3-0.8 |

0.8-1.25 |

|

0.44-0.65 |

|

485-655 |

275 |

22 |

197 |

|

WP11 CL1 |

0.05-0.15 |

0.5-1 |

0.03 |

0.03 |

0.3-0.6 |

1-1.5 |

|

0.44-0.65 |

|

415-585 |

205 |

22 |

197 |

|

WP11 CL2 |

0.05-0.2 |

0.5-1 |

0.04 |

0.04 |

0.3-0.8 |

1-1.5 |

|

0.44-0.65 |

|

485-655 |

275 |

22 |

197 |

|

WP11 CL3 |

0.05-0.2 |

0.5-1 |

0.04 |

0.04 |

0.3-0.8 |

1-1.5 |

|

0.44-0.65 |

|

520-690 |

310 |

22 |

197 |

|

WP22 CL1 |

0.05-0.15 |

0.5 |

0.04 |

0.04 |

0.3-0.6 |

1.9-2.6 |

|

0.87-1.13 |

|

415-585 |

205 |

22 |

197 |

|

WP22 CL3 |

0.05-0.15 |

0.5 |

0.04 |

0.04 |

0.3-0.6 |

1.9-2.6 |

|

0.87-1.13 |

|

520-690 |

310 |

22 |

197 |

|

WP5 CL1 |

0.15 |

0.5 |

0.03 |

0.04 |

0.3-0.6 |

4-6 |

|

0.44-0.65 |

|

415-585 |

205 |

22 |

217 |

|

WP5 CL3 |

0.15 |

0.5 |

0.03 |

0.04 |

0.3-0.6 |

4-6 |

|

0.44-0.65 |

|

520-690 |

310 |

22 |

217 |

|

WP9 CL1 |

0.15 |

1 |

0.03 |

0.03 |

0.3-0.6 |

8-10 |

|

0.9-1.1 |

|

415-585 |

205 |

22 |

217 |

|

WP9 CL3 |

0.15 |

1 |

0.03 |

0.03 |

0.3-0.6 |

8-10 |

|

0.9-1.1 |

|

520-690 |

310 |

22 |

217 |

|

WPR |

0.2 |

|

0.05 |

0.045 |

0.4-1.06 |

|

1.6-2.24 |

|

|

435-605 |

315 |

22/28 |

217 |

|

WP91 |

0.08-0.12 |

0.2-0.5 |

0.01 |

0.02 |

0.3-0.6 |

8-9.5 |

0.4 |

0.85-1.05 |

See sdandard |

585-760 |

415 |

20 |

248 |

|

WP911 |

0.09-0.13 |

0.1-0.5 |

0.01 |

0.02 |

0.3-0.6 |

8.5-10.5 |

0.4 |

0.9-1.1 |

See sdandard |

620-840 |

440 |

20 |

248 |

Notes:

For each reduction of 0.01% below the specified C maximum, an increase of 0.06% Mn above the specified maximum will be permitted, up to a maximum of 1.35%.

The sum of Cu, Ni, Cr, and Mo shall not exceed 1.00%.

The sum of Cr and Mo shall not exceed 0.32%.

The maximum carbon equivalent (C.E.) shall be 0.50, based on heat analysis and the formula C.E.=C+Mn/6+(Cr+Mo+V)/5+(Ni+Cu)/15.

Mechanical properties of ASTM A234

Mechanical properties of ASTM A234

|

Tensile Requirements |

WPB |

WPC, WP11CL2 |

WP11CL1 |

WP11CL3 |

|

Tensile Strength, min, ksi[MPa] |

60-85 |

70-95 |

60-85 |

75-100 |

|

Yield Strength, min, ksi[MPa] |

32 |

40 |

30 |

45 |

ASTM A403

ASTM A403 Standard specification covers the standard for wrought austenitic stainless steel fittings for pressure piping applications.

Chemical Composition (%) of ASTM A403

Chemical Composition (%) of ASTM A403

|

Steel No. |

Type |

C |

Si |

S |

P |

Mn |

Cr |

Ni |

Mo |

Other |

ób |

ós |

δ5 |

|

WP304 |

0.08 |

1 |

0.03 |

0.045 |

2 |

18-20 |

8-11 |

|

|

515 |

205 |

28 |

|

|

WP304H |

0.04-0.1 |

1 |

0.03 |

0.045 |

2 |

18-20 |

8-11 |

|

|

515 |

205 |

28 |

|

|

WP304L |

0.035 |

1 |

0.03 |

0.045 |

2 |

18-20 |

8-13 |

|

|

485 |

170 |

28 |

|

|

WP304LN |

0.03 |

0.75 |

0.03 |

0.045 |

2 |

18-20 |

8-10.5 |

|

N2:0.1-0.16 |

515 |

205 |

28 |

|

|

WP304N |

0.08 |

0.75 |

0.03 |

0.045 |

2 |

18-20 |

8-11 |

|

N2:0.1-0.16 |

550 |

240 |

28 |

|

|

WP309 |

0.15 |

1 |

0.03 |

0.045 |

2 |

22-24 |

12-15 |

|

|

515 |

205 |

28 |

|

|

WP310 |

0.15 |

1.5 |

0.03 |

0.045 |

2 |

24-26 |

19-22 |

|

|

515 |

205 |

28 |

|

|

WP316 |

0.08 |

1 |

0.03 |

0.045 |

2 |

16-18 |

10-14 |

2-3 |

|

515 |

205 |

28 |

|

|

WP316H |

0.04-0.1 |

1 |

0.03 |

0.045 |

2 |

16-18 |

10-14 |

2-3 |

|

515 |

205 |

28 |

|

|

WP316LN |

0.03 |

0.75 |

0.03 |

0.045 |

2 |

16-18 |

11-14 |

2-3 |

N2:0.1-0.16 |

515 |

205 |

28 |

|

|

WP316L |

0.035 |

1 |

0.03 |

0.045 |

2 |

16-18 |

10-16 |

2-3 |

|

485 |

170 |

28 |

|

|

WP316N |

0.08 |

0.75 |

0.03 |

0.045 |

2 |

16-18 |

11-14 |

2-3 |

N2:0.1-0.16 |

550 |

240 |

28 |

|

|

WP317 |

0.08 |

1 |

0.03 |

0.045 |

2 |

18-20 |

11-15 |

3-4 |

|

515 |

205 |

28 |

|

|

WP317L |

0.03 |

1 |

0.03 |

0.045 |

2 |

18-20 |

11-15 |

3-4 |

|

515 |

205 |

28 |

|

|

WP321 |

0.08 |

1 |

0.03 |

0.045 |

2 |

17-20 |

9-13 |

|

Ti:5C-0.7 |

515 |

205 |

28 |

|

|

WP321H |

0.04-0.1 |

1 |

0.03 |

0.045 |

2 |

17-20 |

9-13 |

|

Ti:4C-0.7 |

515 |

205 |

28 |

|

|

WP347 |

0.08 |

1 |

0.03 |

0.045 |

2 |

17-20 |

9-13 |

|

Nb+Ta:10C-1.1 |

515 |

205 |

28 |

|

|

WP347H |

0.04-0.1 |

1 |

0.03 |

0.045 |

2 |

17-20 |

9-13 |

|

Nb+Ta:8C-1 |

515 |

205 |

28 |

|

|

WP348 |

0.08 |

1 |

0.03 |

0.045 |

2 |

17-20 |

9-13 |

|

Ta:0.1 |

515 |

205 |

28 |

|

|

WP348H |

0.04-0.1 |

1 |

0.03 |

0.045 |

2 |

17-20 |

9-13 |

|

Ta:0.1 |

515 |

205 |

28 |

|

Notes:

For each reduction of 0.01% below the specified C maximum, an increase of 0.06% Mn above the specified maximum will be permitted, up to a maximum of 1.35%.

The sum of Cu, Ni, Cr, and Mo shall not exceed 1.00%.

The sum of Cr and Mo shall not exceed 0.32%.

The maximum carbon equivalent (C.E.) shall be 0.50, based on heat analysis and the formula C.E.=C+Mn/6+(Cr+Mo+V)/5+(Ni+Cu)/15.

Mechanical properties of ASTM A403

Mechanical properties of ASTM A403

|

Grade |

UNS |

Tensile Strength, min |

Yield Strength,min |

Elongation min % in 4D |

|||

|

ksi |

MPa |

ksi |

MPa |

Longit % |

Trans% |

||

|

ALL |

ALL |

75 |

515 |

30 |

205 |

28 |

20 |

|

304L |

S30403 |

70 |

485 |

25 |

170 |

28 |

20 |

|

316L |

S31603 |

70 |

485 |

25 |

170 |

28 |

20 |

|

304N |

S30451 |

80 |

550 |

35 |

240 |

28 |

20 |

|

316N |

S31651 |

80 |

550 |

35 |

240 |

28 |

20 |

|

S31726 |

80 |

550 |

35 |

240 |

28 |

20 |

|

|

XM-19 |

S20910 |

100 |

690 |

55 |

380 |

28 |

20 |

|

S31254 |

94-119 |

650-820 |

44 |

300 |

28 |

20 |

|

|

S34565 |

115 |

795 |

60 |

415 |

28 |

20 |

|

|

S33228 |

73 |

500 |

27 |

185 |

28 |

20 |

|

Material Furnished to this specification shall conform to the requirements of specifications A960/A960M including any supplementary requirements that are indicates in the purchase order. Failure to company with the common requirements of Specification A960/A960M constitutes non-conformance with this specification . In case of conflict between this specification and Specification A960/A960M , this specification shall prevail.

ASTM A420

ASTM A420/A420M-07 standard specification for piping fittings of wrought carbon steel and alloy steel for low-temperature service.

Chemical Composition (%) of ASTM A420

Chemical Composition (%) of ASTM A420

|

Elements |

WPL6, % |

WPL9, % |

WPL3, % |

WPL8, % |

|

Carbon [C] |

≤0.30 |

≤0.20 |

≤0.20 |

≤0.13 |

|

Manganese [Mn] |

0.50-1.35 |

0.40-1.06 |

0.31-0.64 |

≤0.90 |

|

Phosphorus [P] |

≤0.035 |

≤0.030 |

≤0.05 |

≤0.030 |

|

Sulfur [S] |

≤0.040 |

≤0.030 |

≤0.05 |

≤0.030 |

|

Silicon [Si] |

0.15-0.40 |

… |

0.13-0.37 |

0.13-0.37 |

|

Nickel [Ni] |

≤0.40 |

1.60-2.24 |

3.2-3.8 |

8.4-9.6 |

|

Chromium [Cr] |

≤0.30 |

... |

... |

... |

|

Molybdenum [Mo] |

≤0.12 |

... |

... |

... |

|

Copper [Cu] |

≤0.40 |

0.75-1.25 |

… |

… |

|

Columbium [Cb] |

≤0.02 |

... |

... |

... |

|

Vanadium[V] |

≤0.08 |

... |

... |

... |

Notes:

* For grade WPL6, the limit for Columbium may be increased up to 0.05% on heat analysis and 0.06% on product analysis.

* Fittings of WPL3 made from plate or forgings may have 0.90 % max manganese.

* Fittings of WPL8 made from plate may have 0.98 % max manganese.

Mechanical properties of ASTM A420

Mechanical properties of ASTM A420

|

ASTM A420/ A420M |

Tensile Strength, min. |

Yield Strength, min. |

Elongation %, min |

|||

|

Grade |

ksi |

MPa |

ksi |

MPa |

Longitudinal |

Transverse |

|

WPL6 |

65-95 |

415-655 |

35 |

240 |

22 |

12 |

|

WPL9 |

63-88 |

435-610 |

46 |

315 |

20 |

… |

|

WPL3 |

65-90 |

450-620 |

35 |

240 |

22 |

14 |

|

WPL8 |

100-125 |

690-865 |

75 |

515 |

16 |

… |

* All the elongation values are on the basis of standard round specimen, or small proportional specimen, min % in 4 D.

ASTM A234 is Standard Specification for steel pipe fittings includes carbon and alloy steel material for moderate and high temperature services.

MSS SP-97

MSS SP-97 Standard Practice covers essential dimensions, finish, tolerances, testing, marking, material, and minimum strength requirements for 90 degree integrally reinforced forged branch outlet fittings of buttwelding, socket welding, and threaded types.

Chemical Composition Requirements of MSS SP 75

Chemical Composition Requirements of MSS SP 75

|

Elements |

Value, % |

|

Carbon (C) |

≤0.30 |

|

Manganese (Mn) |

≤1.60 |

|

Phosphorus (P) |

≤0.035 |

|

Sulfur (S) |

≤0.035 |

|

Copper (Cu) |

≤0.50 |

|

Nickel (Ni) |

≤0.50 |

|

Silicon (Si) |

≤0.50 |

|

Chromium (Cr) |

≤0.25 |

|

Molybdenum (Mo) |

≤0.13 |

|

Vanadium (V) |

≤0.13 |

|

Columbium (Cb) |

≤0.10 |

|

Titanium(Ti) |

≤0.05 |

* The sum of Cu, Ni, Cr and Mo shall not exceed 1%.

* Carbon equivalent C.E.=C+Mn/6+(Cr+Mo+V)/5+(Ni+Cu)/15 shall not exceed 0.45%.

HuNan Province

+86-731-85648266

LiaoNing Province

+86-731-85648266

HeBei Province

+86-731-85648299

jiangsu Province

+86-731-85648299

TianJin City

Singapore