|

STANDARD |

WERKSTOFF NR. |

UNS |

JIS |

GOST |

EN |

OR |

|

Hastelloy C276 |

2.4819 |

N10276 |

NW 0276 |

ХН65МВУ |

NiMo16Cr15W |

ЭП760 |

|

Hastelloy C22 |

2.4602 |

N06022 |

NW 6022 |

- |

NiCr21Mo14W |

- |

|

Hastelloy B2 |

2.4617 |

N10665 |

- |

- |

- |

- |

Hastelloy alloy Pipe Specifications

Hastelloy alloy Pipe Specifications

|

STANDARD |

WERKSTOFF NR. |

UNS |

JIS |

GOST |

EN |

OR |

|

Hastelloy C276 |

2.4819 |

N10276 |

NW 0276 |

ХН65МВУ |

NiMo16Cr15W |

ЭП760 |

|

Hastelloy C22 |

2.4602 |

N06022 |

NW 6022 |

- |

NiCr21Mo14W |

- |

|

Hastelloy B2 |

2.4617 |

N10665 |

- |

- |

- |

- |

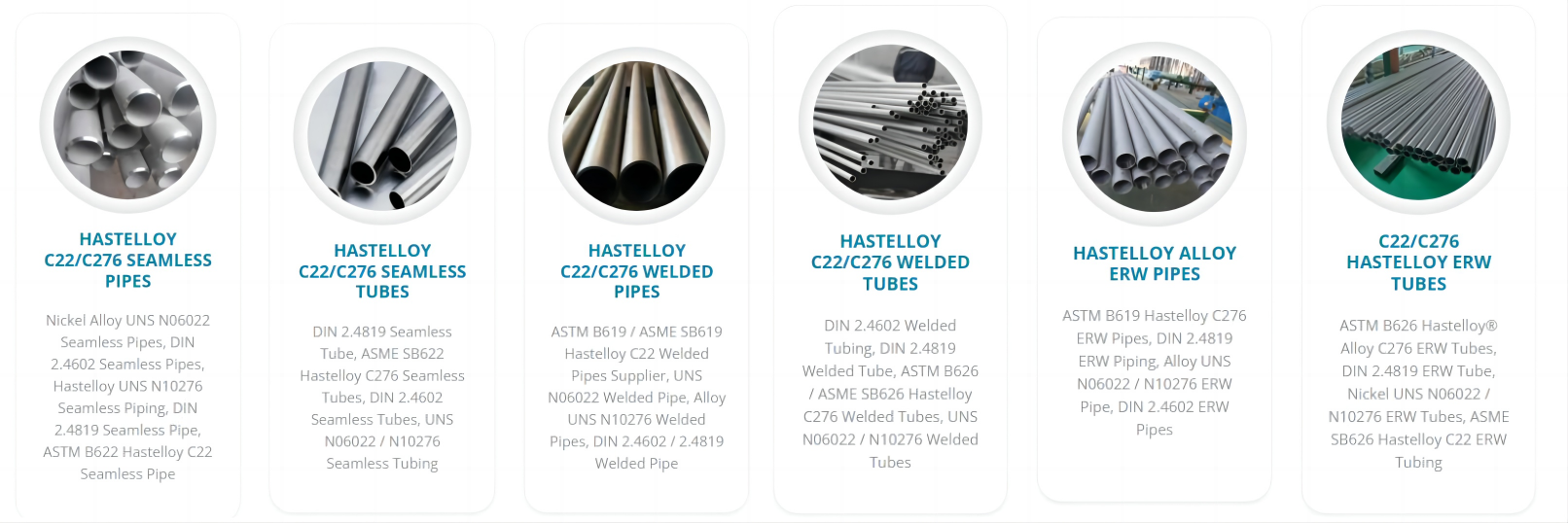

Hastelloy C22/C276 Pipes and Tubes Other Types

Hastelloy C22/C276 Pipes and Tubes Other Types

|

Types |

Out diameter |

Wall thickness |

Length |

|

NB Sizes (in stock) |

1/8” ~ 8” |

SCH 5 / SCH 10 / SCH 40 / SCH 80 / SCH 160 |

Upto 6 Meters |

|

Hastelloy Seamless Pipe (Custom Sizes) |

5.0mm ~ 203.2mm |

As per requirement |

Upto 6 Meters |

|

Hastelloy Welded Pipe (in Stock + Custom Sizes) |

5.0mm ~ 1219.2mm |

1.0 ~ 15.0 mm |

Upto 6 Meters |

The pipes are well tested in the industry for quality assurance. The tests conducted are positive material identification test,

flattening test, mechanical test, chemical test, intergranular corrosion test, flaring test, hardness test etc

Hastelloy alloy Pipe Tolerance Table

Hastelloy alloy Pipe Tolerance Table

|

Alloy C276 |

NI |

MO |

CR |

FE |

W |

CO |

MN |

C |

|

Remainder |

15.0-17.0 |

14.5-16.5 |

4.0-7.0 |

3.0-4.5 |

2.5 max |

1.0 max |

.01 max |

|

|

V |

P |

S |

Si |

|

|

|

|

|

|

.35 max |

.04 max |

.03 max |

.08 max |

|

|

|

|

|

|

Alloy C22 |

C |

CR |

CO |

FE |

MN |

MO |

NI |

P |

|

.010 max |

20-22.5 |

2.5 max |

2.0-6.0 |

.50 max |

12.5-14.5 |

Balance |

.02 max |

|

|

Si |

S |

W |

V |

|

|

|

|

|

|

.08 max |

.02 max |

2.5-3.5 |

.35 max |

|

|

|

|

|

|

Alloy B2 |

NI |

MO |

FE |

C |

CO |

CR |

MN |

SI |

|

Balance |

26.0-30.0 |

2.0 max |

.02 max |

1.0 max |

1.0 max |

1.0 max |

.10 max |

|

|

P |

S |

|

|

|

|

|

|

|

|

.040 max |

.030 max |

|

|

|

|

|

|

Hastelloy alloy Pipe Chemical Composition

Hastelloy alloy Pipe Chemical Composition

| Hastelloy C276 | Ni | C | Mo | Mn | Si | Fe | P | S | Co | Cr |

| Balance | 0.010 Max | 15.00 – 17.00 | 1.00 Max | 0.08 Max | 4.00 – 7.00 | 0.04 Max | 0.03 Max | 2.5 Max | 14.50 – 16.50 | |

| Hastelloy C22 | Balance | 0.010 Max | 12.5 – 14.5 | 0.50 Max | 0.08 Max | 2 – 6 | 0.02 Max | 0.02 Max | 2.5 Max | 20 – 22 |

Hastelloy alloy Pipe Mechanical Properties

Hastelloy alloy Pipe Mechanical Properties

|

|

Melting Point |

Tensile Strength |

Yield Strength (0.2%Offset) |

Elongation |

|

|

C22 |

8.69 G/Cm3 |

1399 °C (2550 °F) |

Psi – 1,00,000 , MPa – 690 |

Psi – 45000 , MPa – 310 |

45 % |

|

C276 |

8.89 G/Cm33 |

1370 °C (2500 °F) |

Psi – 1,15,000 , MPa – 790 |

Psi – 52,000 , MPa – 355 |

40% |

|

B2 |

9.2 G/Cm3 |

1370 °C (2550 °F) |

Psi – 1,15,000 , MPa –760 |

Psi – 52,000 , MPa – 350 |

40% |

|

B3 |

9.2 G/Cm3 |

1370 °C (2550 °F) |

Psi – 1,15,000 , MPa –760 |

Psi – 52,000 , MPa – 350 |

40% |

|

C4 |

8.64 G/Cm3 |

1350-1400 °C |

783 |

365 |

55% |

|

Hybrid BC1 |

8.83 G/Cm³ |

1343 - 1443°C |

725 |

310 |

40% |

|

X |

8.22 G/Cm³ |

1355°C |

655 MPa |

240 MPa |

35% |

HuNan Province

+86-731-85648266

LiaoNing Province

+86-731-85648266

HeBei Province

+86-731-85648299

jiangsu Province

+86-731-85648299

TianJin City

Singapore