Area

15000㎡Number of workers

Over 300 workersProduct

Carbon Seamless Steel Pipe,APL5L Line Pipe,Heat Exchanger Tubes,Precision Steel PipeFacility

Annual output

20000 tonnes for SMLS pipe

Factory Introduction

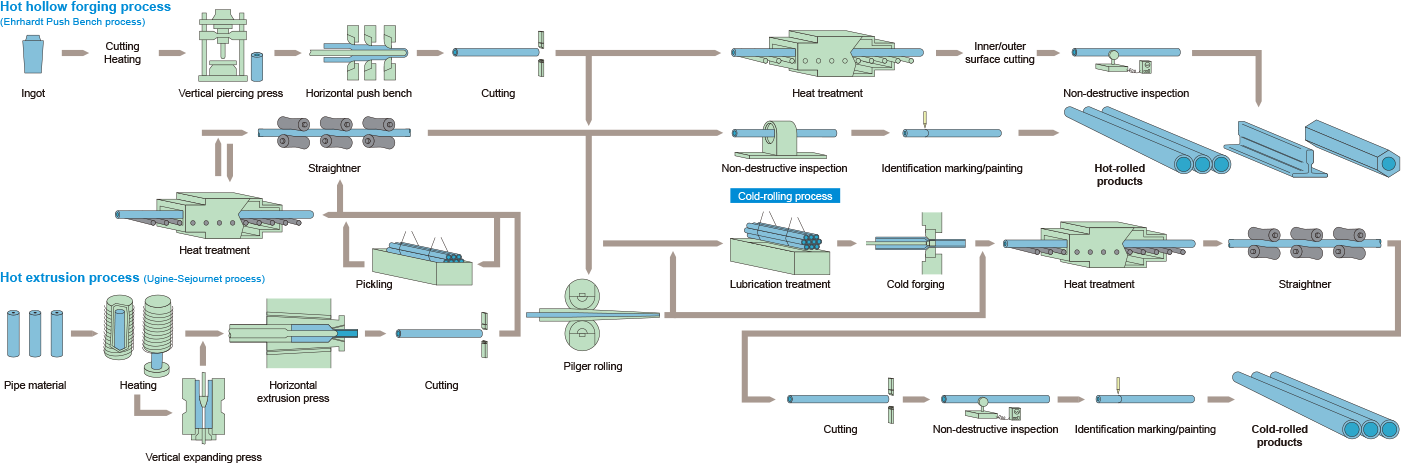

The factory optimizes and innovates on the basis of the existing domestic seamless steel pipe production process, and introduces the key control devicemanufactured by the German SMS Meer factory with the world's advanced level, and designs a new type of medium 219A-R heat pipe in line with the company's own characteristics. The combination of rolling production lines can not only adapt to the rolling of multi-specification tube blanks, but also improve product quality and reduce energy consumption. The designed capacity of rolling tubes is 200,000 tons.

The deep processing of seamless steel pipe is anotherhighlight of the factory. It has 1 pipe end thickening linefor 800 tons/400 tons, 2 pipe thread processing lines foroil wells, 1 drill pipe production line, 1 heat treatment line,and 1 finishing line. , 1 eddy current flaw detection line,1 surface polishing and rust removal line, 4 ultrasonic flaw detection lines,4 hydraulic test lines,1 automatic chamfering anti-corrosion packaging line, and introduced the internationally advanced MAC ultrasonic flaw detectorfrom the US magnetic factory And the first-class equipmentsuch as full-length thickness gauge, four-axis high-efficiencywire machine in Danobac factory in Spain, domestic leading walking beam heat treatment furnace, and Zhejiang University lean and efficient chamfering anti-corrosion packaging line, with a processing capacity ofmore than 200 pieces per hour. At the same time, it also introduced testing equipment such as ARL spectrometer from Thermo Fisher Factory in Switzerland and SANS tensile testing machine from MTS Factory in the United States.

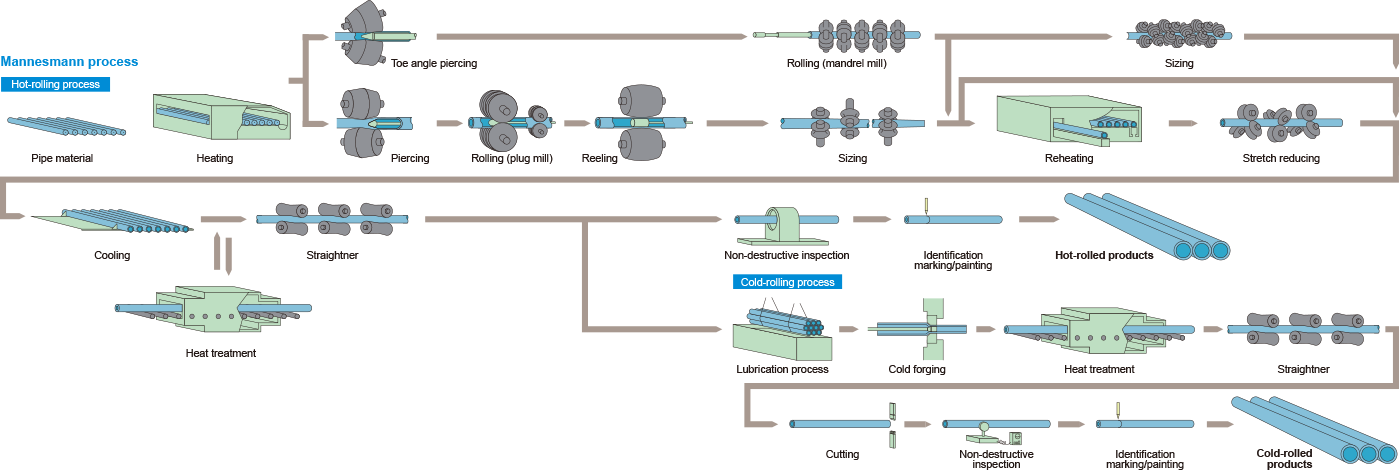

Weldless pipes and pipes (Mannesmann process)

Weldless pipes and pipes (Mannesmann process)

USI Group has a quality inspection center to provide inspection services for the production process and finished products,Learn more about the Inspection process!