| Product: | Drill Pipe |

| Application: | Used for Mine, water well drilling, well drilling, coal and fore poling |

| Size: | OD: 2-3/8" to 7-5/8" |

| WT: 6.45-12.7mm | |

| LENGTH: R1, R2, R3 | |

| Pipe Standard: | API 5DP E75, X95, G105, S135 |

| Upset Style: | IU, EU, IEU |

| Connection: | NC26, NC31, NC38, NC40, NC46, NC50, 5 1/2FH.6 5/8FH. |

| Internal coating | TK34,TC2000, Arnco 100XT, 200XT, 300XT |

Drill Pipe Introduction

Drill Pipe Introduction|

Product: |

Drill Pipe |

|

Application: |

Used for Mine, water well drilling, well drilling, coal and fore poling |

|

Size: |

OD: 2-3/8" to 7-5/8" |

|

WT: 6.45-12.7mm |

|

|

LENGTH: R1, R2, R3 |

|

|

Pipe Standard: |

API 5D,API 5DP E75, X95, G105, S135 |

|

Upset Style: |

IU, EU, IEU |

|

Connection: |

NC26, NC31, NC38, NC40, NC46, NC50, 5 1/2FH.6 5/8FH. |

|

Internal coating |

TK34,TC2000, Arnco 100XT, 200XT, 300XT |

Types of Drill Pipe

Types of Drill Pipe

Drill collars are a component of the drill string that makes up part of the BHA. They are thicker-walled, heavier, and more rigid than drill pipes and are primarily used to weigh down the drill bit while dampening vibration and impact forces.

OCTG Drill Pipe Proprietary Grades

OCTG Drill Pipe Proprietary Grades

Proprietary grades often exceed the specifications set forth by API SPEC 5DP. Their enhanced performance properties are developed for sour service, critical service, and other user-defined requirements.

Sour service grades resist sulphide stress corrosion (SSC). SSC can occur when hydrogen sulfide is present. Ingress of hydrogen coupled with higher stresses, low temperatures, low pH, and high chloride content decreases the ductility of steel grades leaving them susceptible to crack propagation and failure.

Critical service grades resist corrosion when sweet gas or high concentrations of carbon dioxide are present. They are a cost effective alternative that is used in water injection applications.

Drill Pipe Size

Drill Pipe Size

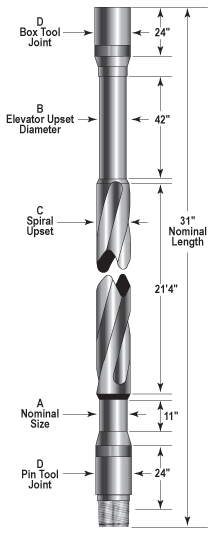

Drill pipe is manufactured according to standard specifications and is offered in nominal sizes. The two most important dimensional specifications are length and diameter.

Drill Pipe Length

Drill Pipe Length

The drill string is made up of several sections of drill pipe. The term "stand" refers to two or three sections of drill pipe that are fed into the well bore to complete 60 to 90 feet of drilling. Each segment of pipe, referred to as a "single", is classified by API into three distinct length ranges; R1, R2, and R3.

Range 1 (R1) is shortest in length, more common for sizing production tubing or casing, and ranges from 18 to 22 ft.

Range 2 (R2) is considered the standard length for drill pipe and ranges from 27 to 31 ft.

Range 3 (R3) is common in casing and also deployed in deep water drilling applications. The increased length decreases the number of tool joints in each stand of drill pipe. The fall back being that the load exerted on each tool joint is greater increasing wear and reducing the expected life of the drill pipe. R3 ranges from 38 to 45 ft.

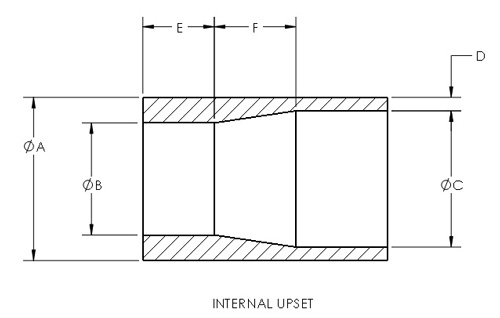

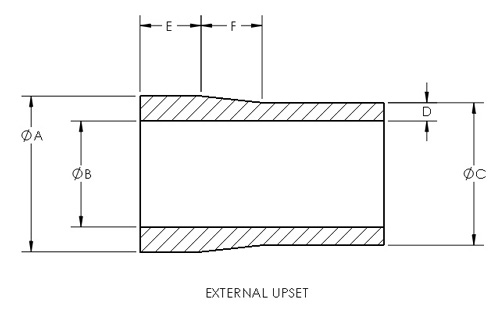

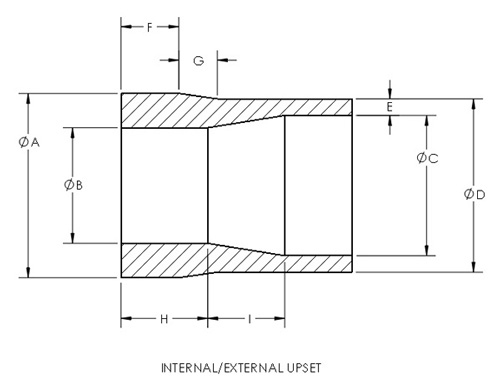

Upset

Upset

The upset (thread-end finish) refers to the wall of the tool joint at the threaded connection. Drill pipe is offered with an internal upset (IU), an external upset (EU), or an internal-external upset (IEU).

IU - In an internal upset increased thickness along the inside walls compensate for the metal removed in threading with a uniform, straight outside wall.

EU - In an external upset the increased thickness along the outside diameter of the tubing compensates for the metal removed in threading with a straight bore.

IEU - In an internal-external upset thickness is increased along both the inside and outside walls of the pipe to compensate for the metal removed in threading.

Threaded Connection of API Drill Pipe

Threaded Connection of API Drill Pipe

Tool joints incorporate threaded connections. They include standard API threads as well as proprietary threads. Each type of threaded connection is specified by threads per inch (TPI) and it's taper. Common API tool joints include regular (REG), full-hole (FH), and internal-flush (IF).

Features of Drill Pipe

Features of Drill Pipe

API Grade Drill Pipe

API Grade Drill Pipe

|

API Drill Pipe Grade |

Minimum Yield Strength (psi) |

Minimum Tensile Strength (psi) |

|

E-75 |

75,000 |

100,000 |

|

X-95 |

95,000 |

105,000 |

|

G-105 |

105,000 |

115,000 |

|

S-135 |

135,000 |

145,000 |

Drill Pipe Dimensions

Drill Pipe Dimensions

|

Size designation |

Calculated weight |

Tool joint designation |

Calculated weight |

grade |

Wall thickness |

Upset ends |

||

|

in |

1b/ft |

Kg/m |

in |

mm |

||||

|

2 3/8 |

6.65 |

NC26 |

6.26 |

9.32 |

E.X.G.S |

0.28 |

7.11 |

EU |

|

2 7/8 |

10.4 |

NC31 |

9.72 |

14.48 |

E.X.G.S |

0.362 |

9.19 |

EU |

|

3 1/2 |

13.3 |

NC38 |

12.31 |

18.34 |

E.X.G.S |

0.368 |

9.35 |

EU |

|

3 1/2 |

15.5 |

NC38,NC40 |

14.63 |

21.79 |

E.X.G.S |

0.449 |

11.4 |

EU |

|

4 |

14 |

NC40,NC46 |

12.93 |

19.26 |

E.X.G.S |

0.33 |

8.38 |

IU,EU |

|

4 1/2 |

16.6 |

NC46,NC50 |

14.98 |

22.31 |

E.X.G.S |

0.337 |

8.56 |

EU,IEU |

|

4 1/2 |

20 |

NC46,NC50 |

18.69 |

27.84 |

E.X.G.S |

0.43 |

10.92 |

EU,IEU |

|

5 |

19.5 |

NC50,NC52 |

17.93 |

26.71 |

E.X.G.S |

0.362 |

9.19 |

IEU |

|

5 |

25.6 |

NC50,5 1/2FH |

24.03 |

35.79 |

E.X.G.S |

0.5 |

12.7 |

IEU |

|

5 1/2 |

21.9 |

5 1/2FH |

19.81 |

29.51 |

E.X.G.S |

0.361 |

9.17 |

IEU |

|

5 1/2 |

24.7 |

5 1/2FH |

22.54 |

33.57 |

E.X.G.S |

0.415 |

10.54 |

IEU |

|

6 5/8 |

25.2 |

6 5/8FH |

22.19 |

33 |

E.X.G.S |

0.33 |

8.387 |

IEU |

|

6 5/8 |

27.7 |

6 5/8FH |

24.21 |

41 |

E.X.G.S |

0.362 |

9.19 |

IEU |

Chemical Composition(%)

Chemical Composition(%)

|

Grade |

Chemical composition |

|

|

P |

S |

|

|

E75 |

<0.015 |

<0.003 |

|

X95 |

<0.015 |

<0.003 |

|

G105 |

<0.015 |

<0.003 |

|

S135 |

<0.015 |

<0.003 |

|

Tool joint |

<0.015 |

<0.003 |

Mechanical Properties

Mechanical Properties

|

Pipe body |

Grade |

Yield strength |

Tensile strength |

Elongation |

Hardness |

Full size charpy impact test(J) |

||||||

|

min |

max |

min |

min |

|||||||||

|

Psi |

MPa |

Psi |

MPa |

Psi |

MPa |

HBW |

HRC |

Average |

Single |

|||

|

E75 |

75000 |

517 |

105000 |

724 |

100000 |

689 |

625000A0.2/U0.9 |

- |

- |

80 |

65 |

|

|

X95 |

95000 |

655 |

125000 |

862 |

105000 |

724 |

- |

- |

80 |

65 |

||

|

G105 |

105000 |

724 |

135000 |

931 |

115000 |

793 |

- |

- |

80 |

65 |

||

|

S135 |

135000 |

931 |

165000 |

1138 |

145000 |

1000 |

- |

- |

80 |

65 |

||

|

Weld zone |

Tool joint |

120000 |

827.4 |

- |

- |

140000 |

965.3 |

=13% |

=285 |

- |

80 |

65 |

|

E75 |

75000 |

517 |

- |

- |

100000 |

689 |

- |

?37 |

40 |

27 |

||

|

X95 |

88000 |

609 |

- |

- |

103000 |

712 |

- |

?37 |

40 |

27 |

||

|

G105 |

95000 |

655 |

- |

- |

105000 |

724 |

- |

?37 |

40 |

27 |

||

|

S135 |

105000 |

724 |

- |

- |

115000 |

|

|

?37 |

40 |

27 |

||

HuNan Province

+86-731-85648266

LiaoNing Province

+86-731-85648266

HeBei Province

+86-731-85648299

jiangsu Province

+86-731-85648299

TianJin City

Singapore