Area

25000㎡Number of workers

Over 500 workersProduct

SSAW Pipe,submerged arc welded steel pipeFacility

equipped with hydraulic testing machine, X-ray industrial TV, offline ultrasonicAnnual output

30000 tonnes for SSAW pipe

Factory introduction

The SSAW Pipe Factory covers an area of 25000 square

meters. There are 500employees, including 31 engineers

and technicians, 5 with senior professional titles,and an

annual production capacity of 300,000 tons.

The factory can supply 219mm-4500mm (8.62"-177" ) of

the spiral buried Arc welded pipe (SAWH),our company has

strong technical ability, advanced production equipment,

complete inspection and testing equipment, and has

introduced the world's leading American Lincoln welding

machine and British imported automatic welding laser

tracking system, equipped with hydraulic testing machine,

X-ray industrial TV, offline ultrasonic, fixed Diameter

expansion professional equipment, as well as testing

equipment such as optical harmonic instrument imported

from Japan, drop weight testing machine, impact testing

machine (300J at -60°C), hardness tester, and metallographic microscope.

The company's products are widely used in petroleum

and natural gas transportation, urban heating pipe network,

water supply pipeline and sewage treatment, chemical

industry, steel structure, bridge, foundation piling, port

machinery, electric power and other industries. The

company not only produces AP! 5L, ASTM E2, GB/T9711.1, GB/T9711.2 standard steel pipes, but also produces steel

pipes of various specifications according to the needs of

different users. The steel grades can be X42-X100, L245-L485,

GR.A, GR.B, S290 and above, S S400 and above, S T33, ST42,

Q235 (A, B, C), Q345 (B, C, D, R), etc.

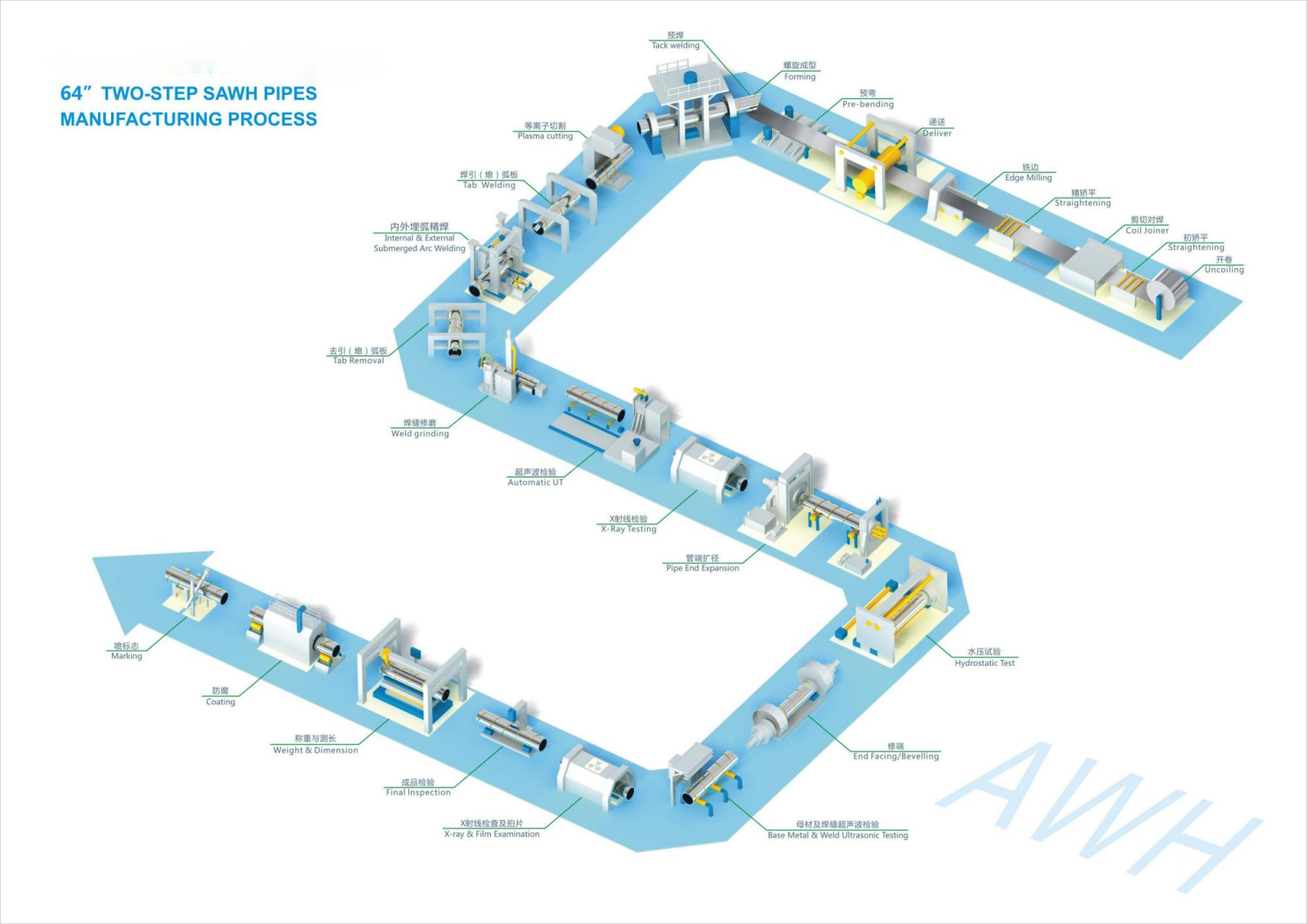

SAWH PIPES Production Line

This production line adopts the most advanced welding process technology, namely Two Step Production Process. The pipes are firstly formed into a pipe body and continuous tack-welded at high speed. In the second process step the pipes are subsequently finally submerged arc welded and that gives a higher quality weld compared with other SAWH production method. This process will eliminate the tensile stress of weld seam during pipe forming and submerged arc welding. It also effectively improves stability of the welded joints and productivities. These products are widely used in onshore oil and gas pipelines.

Specifications

Outside Diameter:Φ508mm-Φ4500mm (20"- 177")

Wall Thickness:6.4-25.4mm(1/4"-1")

Quality Standards:API、DNV、ISO、DEP、EN、ASTM、DIN、BS、JIS、CSA

Length:6-130m(20'-427')

Grades:X42-X100, L245-L485,GR.A, GR.B, S290 and above, S S400 and above, S T33, ST42,Q235 (A, B, C), Q345 (B, C, D, R), etc

USI Group has a quality inspection center to provide inspection services for the production process and finished products,Learn more about the Inspection process!