| Product: | Casing Pipe, Oil Casing, API Casing, Well Casing, Casing |

| Application: | Used for oil casing and tubing in oil wells as well as sidewall |

| Size: | OD: 114.3mm-508mm |

| WT: 5-16mm | |

| LENGTH: R1, R2, R3 | |

| Pipe Standard: | API 5CT PSL1/PSL2 J55,K55,N80-1,N80-Q, |

| API 5CT PSL1/PSL2 L80-1, L80-9Cr,L80-13Cr,C90, C95, P110, Q125 | |

| Thread: | NUE, EUE, STC, LTC, BTC, XC,HYDRILL CS |

| Special Service | Sweet Service, Sour Service, Anti-H2S, NACE MR0175/ISO15156 |

| Accessories: | Pup Joint, Coupling, Drill Collar, Crossover etc. |

OCTG Casing Introduction

OCTG Casing Introduction

|

Product: |

Casing Pipe, Oil Casing, API Casing, Well Casing, Casing |

|

Application: |

Used for oil casing and tubing in oil wells as well as sidewall |

|

Size: |

OD: 114.3mm-508mm |

|

WT: 5-16mm |

|

|

LENGTH: R1, R2, R3 |

|

|

Pipe Standard: |

API 5CT PSL1/PSL2 J55,K55,N80-1,N80-Q, |

|

API 5CT PSL1/PSL2 L80-1, L80-9Cr,L80-13Cr,C90, C95, P110, Q125 |

|

|

Thread: |

NUE, EUE, STC, LTC, BTC, XC,HYDRILL CS |

|

Special Service |

Sweet Service, Sour Service, Anti-H2S, NACE MR0175/ISO15156 |

|

Accessories: |

Pup Joint, Coupling, Drill Collar, Crossover etc. |

|

Oil casing |

R1 |

R2 |

R3 |

|

4.88-7.62m |

7.62-10.36m |

10.36-14.63m |

OCTG Casing Pipe Connections

OCTG Casing Pipe Connections

API 5CT is applicable to following connections which complied with API SPEC 5B:

• SC: Short round thread casing

• LC: Long ound thread casing

• BC: Buttress thread casing

• NU: Non-upset tubing

• EU: External upset tubing

• IJ: Integral tubing connections

Steel Casing Pipe Application

Steel Casing Pipe Application

6, ASTM A192 For manufacture wall panel, economizer, reheater, superheater and vapor pipe of central heating boilers.

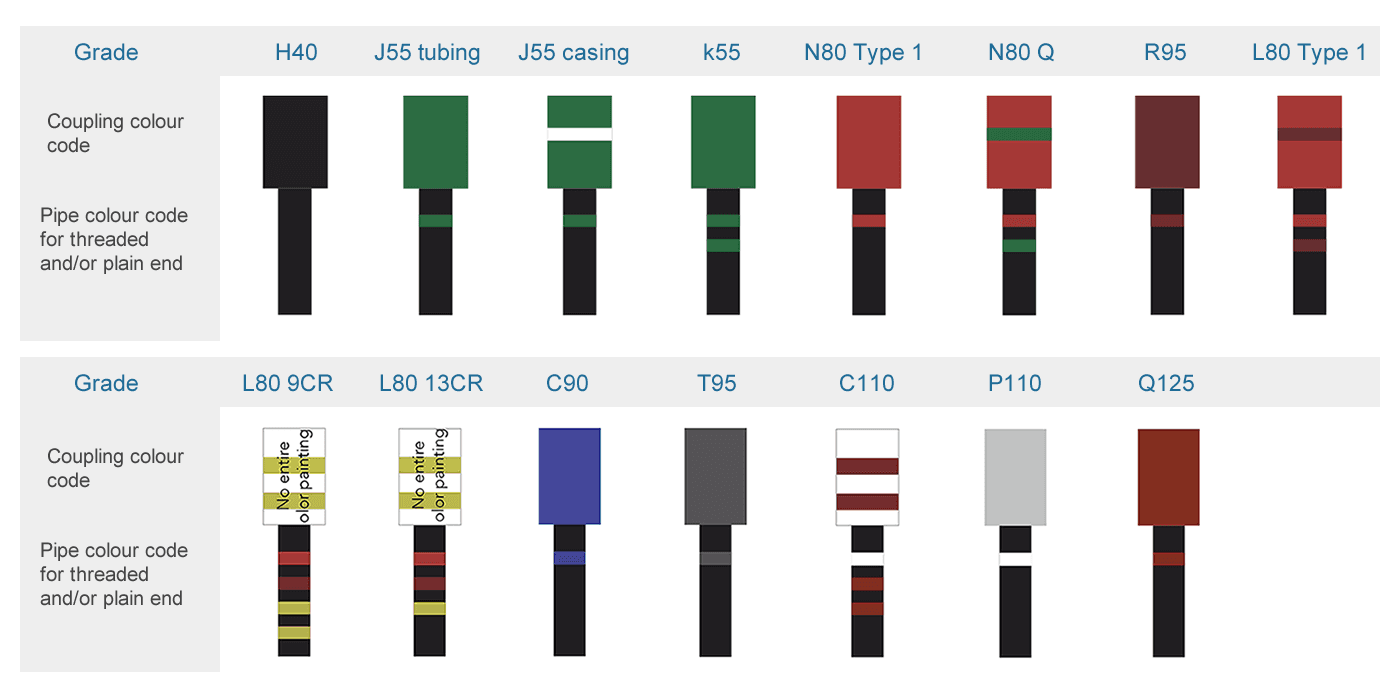

More casing pipes and their colors

More casing pipes and their colors

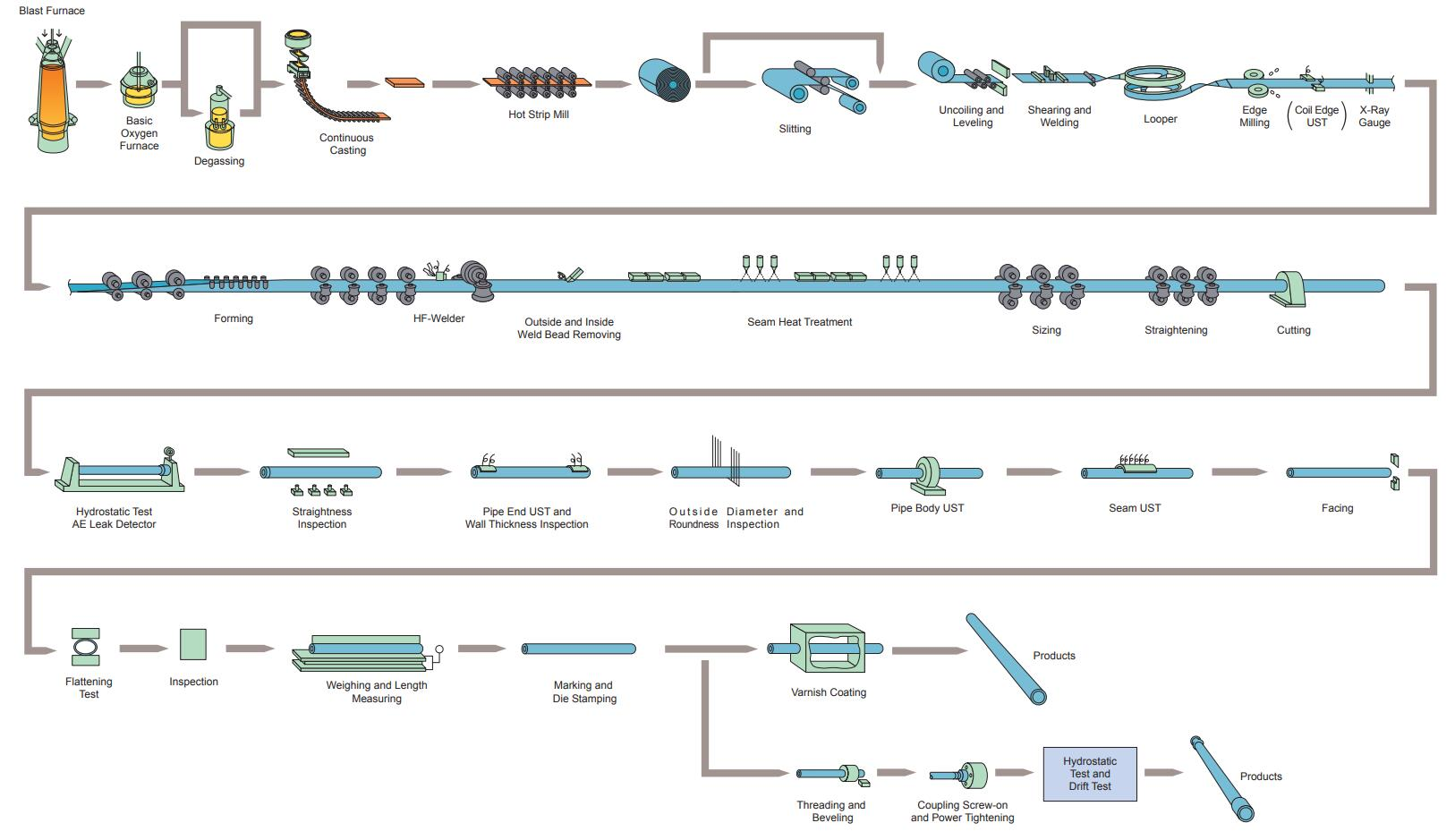

Quality Control System

Quality Control System

API 5CT Casing Pipe Dimension Tolerance

API 5CT Casing Pipe Dimension Tolerance

|

Types of steel tubes |

Outer Diameter |

Wall Thickness |

|

|

Cold-rolled tubes |

Tube sizes(mm) |

Tolerances(mm) |

Tolerances(mm) |

|

<114.3 |

±0.79 |

-12.5% |

|

|

≥114.3 |

-0.5%,+1% |

||

API 5CT Casing Pipe Chemical Compositions

API 5CT Casing Pipe Chemical Compositions

|

Standard |

Grade |

Chemical compositions(%) |

|||||||||

|

J55 |

C |

Si |

Mn |

P |

S |

Cr |

Ni |

Cu |

Mo |

V |

|

|

K55 |

0.34~0.39 |

0.20~0.35 |

1.25~1.50 |

≤0.020 |

≤0.015 |

≤0.15 |

≤0.20 |

≤0.20 |

/ |

/ |

|

|

N80 |

0.34~0.38 |

0.20~0.35 |

1.45~1.70 |

≤0.020 |

≤0.015 |

≤0.15 |

/ |

/ |

/ |

0.11~0.16 |

|

|

L80 |

0.15~0.22 |

≤1.00 |

0.25~1.00 |

≤0.020 |

≤0.010 |

12.0~14.0 |

≤0.20 |

≤0.20 |

/ |

/ |

|

|

P110 |

0.26~0.395 |

0.17~0.37 |

0.40~0.70 |

≤0.020 |

≤0.010 |

0.80~1.10 |

≤0.20 |

≤0.20 |

0.15~0.25 |

≤0 |

|

API 5CT Casing Pipe Mechanical Properties

API 5CT Casing Pipe Mechanical Properties

| Grade | Type |

Total elongation under load (%) |

Yield strength (min) |

Yield strength (max) |

Tensile strength min Mpa |

Hardness Max (HRC) |

Hardness Max (HBW) |

| J55 | - |

0.5 |

379 | 552 | 517 |

|

|

| K55 | - |

0.5 |

379 | 552 | 655 |

|

|

| N80 | 1 |

0.5 |

552 | 758 | 689 |

|

|

| N80 | Q |

0.5 |

552 | 758 | 689 |

|

|

| L80 | 1 |

0.5 |

552 | 655 | 655 | 23 | 241 |

|

L80 |

9Cr |

0.5 |

552 | 655 | 655 | 23 | 241 |

|

L80 |

13Cr |

0.5 |

552 | 655 | 655 | 23 | 241 |

| C90 | - |

0.5 |

621 | 724 | 689 | 25.4 | 255 |

| C95 | - |

0.5 |

655 | 758 | 724 |

|

|

| T95 | - | 0.5 | 655 | 758 | 724 | 25.4 | 255 |

| P110 | - | 0.6 | 758 | 965 | 862 |

|

|

| Q125 | All | 0.65 | 862 | 1034 | 931 |

|

|

HuNan Province

+86-731-85648266

LiaoNing Province

+86-731-85648266

HeBei Province

+86-731-85648299

jiangsu Province

+86-731-85648299

TianJin City

Singapore