|

Item Name |

adjustable pipe clamps, cushioned pipe clamps, rigid clamps, riser pipe clamps, two bolt pipe clamp, three bolt pipe clamp, yoke type pipe clamp |

|

Machining Equipment |

Machining Center / CNC Lathes / Grinding Machines / Milling Machines / Lathes / Wire-cuts / Laser Cuts / CNC Shearing Machines / CNC Bending Machines / etc. |

|

Materials |

Aluminum Alloy: |

|

5052 /6061/ 6063 / 2017 / 7075 / etc. |

|

|

Brass Alloy: |

|

|

3602 / 2604 / H59 / H62 / etc. |

|

|

Stainless Steel Alloy: |

|

|

303 / 304 / 316 / 412 / etc. |

|

|

Steel Alloy: |

|

|

Carbon Steel / Die Steel / etc. |

|

|

Other Special Materials: |

|

|

Lucite / Nylon / Bakelite / etc. |

|

|

We handle many other type of materials. Please contact us if your required material is not listed above. |

|

|

Surface Treatment |

Blacking, polishing, anodize, chrome plating, zinc plating, nickel plating,tinting |

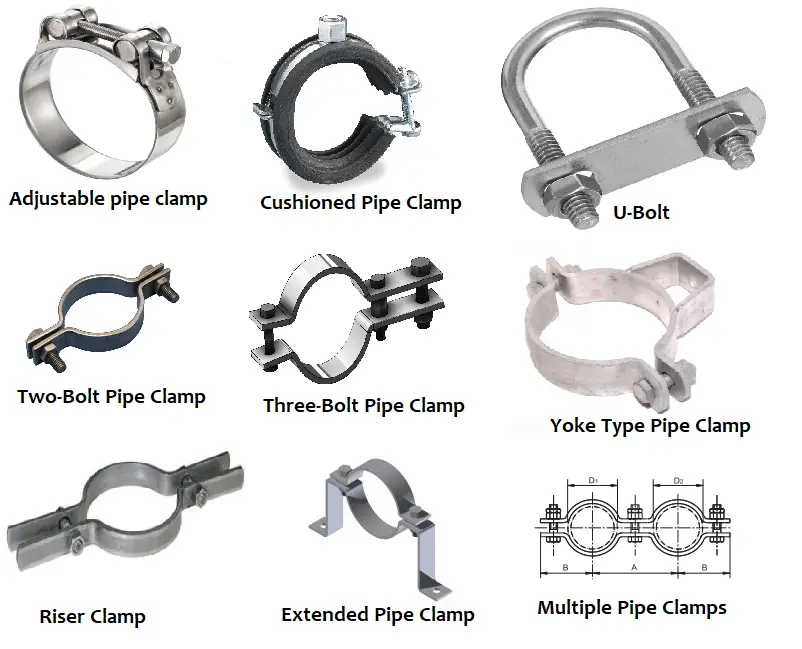

Types of Pipe Clamps

Types of Pipe Clamps

Depending on the purpose, materials, function, use, etc, a wide variety of piping clamps are used in industrial applications. Some of the different types of pipe clamps are explained below:

1. Adjustable Pipe Clamps:

Mostly made from Steel, plastic, or aluminum, these types of piping clamps have the ability to adjust themselves as per the required pipe diameter. They can be easily tightened or loosened as per the pipe OD. As these types of pipe clamps can be universally used for different pipe diameters, they are cost-effective.

2. Cushioned Pipe Clamps:

Containing a cushioning material these type of pipe clamps helps in avoiding galvanic corrosion as metal-to-metal contact is prevented. Widely used for bare pipes, these pipe clamps shall be selected depending on the pipe temperature as the cushioning material should sustain that temperature.

3. Rigid Clamps:

Simple in construction, Rigid clamps are usually made from steel or iron. They are available as single-body pipe clamps or two-piece pipe clamps and can easily be screwed.

4. U bolt Pipe Clamps:

U-bolts are the most widely used type of pipe clamps. U-bolts are extensively used for small-bore piping. They are used to work as rest+guide+hold down or rest+guide+hold down+line stop for small bore piping systems. For pipes with a diameter exceeding 8 inches, their application is reduced to a great extent as the piping loads increase with the increase in pipe sizes.

5. Two Bolt Pipe Clamp:

Two-bolt pipe clamps are used for hanging bare pipes without any insulation. Their load-carrying capability is usually not large.

6. Three Bolt Pipe Clamp:

Three-bolt Pipe Clamps are used for suspending insulated lines carrying high-temperature fluids. The length of the clamps on top of the pipe is increased to accommodate the 3rd bolt which allows the attachment of the pipe clamp outside the insulation. The load-carrying capability of three-bolt pipe clamps is relatively higher than two-bolt pipe clamps.

7. Yoke Type Pipe Clamp:

For hanging of high-temperature horizontal insulated pipes, yoke-type pipe clamps are used. These types of pipe clamps can easily support pipes with 4″ – 6″ insulation.

8. Riser Pipe Clamps:

Riser Pipe Clamps are used to support lines without the use of hanger roads. The pipe loads are transferred by resting both ears of the clamp on the floor or structural member. These types of pipe clamps are not recommended for higher temperatures.

9. Pipe Clips:

Also known as pipe straps, pipe clips are used to support horizontal or vertical lines by bolting the clip directly to a structure.

10. Heavy Duty Pipe Clamps:

Heavy-duty piping clamps are specially designed to support higher piping loads. Most of the pipe clamps are designed in both standard and heavy-duty variants to address different load requirements.

11. Extended Pipe Clamps:

In some applications, the bottom piece of the pipe clamp can be extended and configured to use as a pipe support. These types of piping clamps are known as extended pipe clamps.

12. Multiple Pipe Clamps:

In certain special applications, two or more pipe clamps can be joined together or manufactured to use multiple pipe clamps to support more than one pipe. Multiple pipe clamps are specially fabricated to suit the site requirements.

Pipe Clamps Materials:

Pipe Clamps Materials:

Pipe clamps are manufactured of a wide range of materials like:

Carbon Steel

Stainless Steel

Plastic

Copper

Brass

Aluminum

Alloy Steel

Chrome/Chrome-Plated pipe clamps, etc

Features of Pipe Clamps:

Features of Pipe Clamps:

Most pipe clamps provide the following features:

Simple Operation

Easy installation

Adjustable in a small range

Nice appearance

The temperature range is decided by the clamp lining being used.

All pipe clamps usually have impact resistance.

Quick and easy pipe installation and layout.

Shock-absorption property

Vibration dampening property

Acoustic reduction property

Heavy torque

Suitable for small and large-diameter pipes, etc.

Design moulds → Confirm samples → Purchase material → Blanking → Punching→ Bending → Forming → Surface treatment → Inspection → Assemble products → Package

Our Mitutoyo Tool Microscope can measure up to 300mmX x 175mmY x 220mmZ

Pipe Clamps are made from various materials ranging from plastic to copper, stainless steel, brass and chrome, and are available in numerous different bracketing and mounting options (single-screw, two-screw or three-screw, bolt-down, clip-in, and so on).

Clamp casting profile

|

1. Material percentage |

alloy steel:45% |

|

2. Casting weight percentage |

0.1-5kg:40% |

|

3. Industry percentage |

Components for train & railway: 20% |

|

4. Global market share |

United States:30% |

HuNan Province

+86-731-85648266

LiaoNing Province

+86-731-85648266

HeBei Province

+86-731-85648299

jiangsu Province

+86-731-85648299

TianJin City

Singapore