| Product: | Stainless seamless pipes, Stainless Steel Seamless Pipe |

| Size: | OD: 3-2500 mm |

| WT: 1.0-150 mm | |

| LENGTH: 5.8/6/11.8/12m | |

| Pipe Standard: | ASTM A213, ASTM A312, ASTM A269, ASTM A778, ASTM A789 |

| DIN 17456,DIN 17457,DIN | |

| EN 10216, BS 3605, JIS 3459, JIS3463, GOS T9941 | |

| Material: | 304/L,316/L,201,202,301,347/H,316Ti,309s,310s |

| Process: | Cold drawn, Cold rolled, Precision Rolled |

| Finish: | Annealed & pickled, bright annealing, polished |

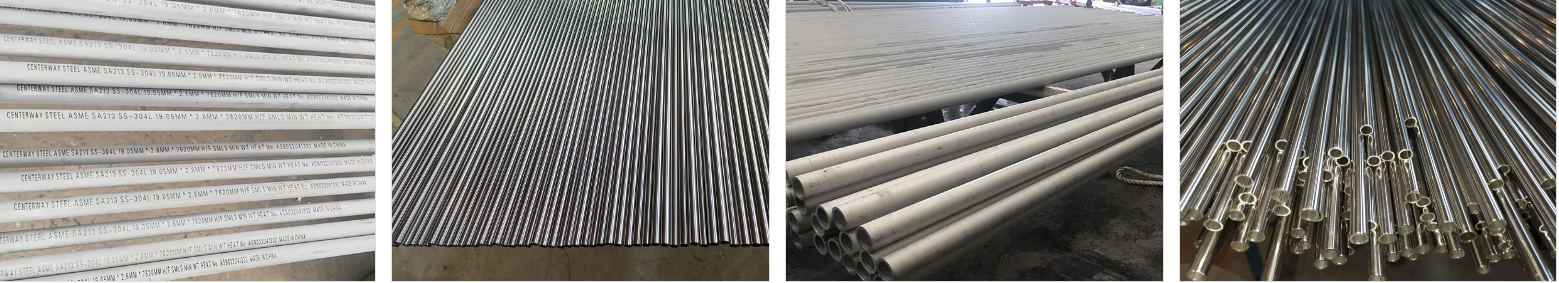

Stainless Seamless Steel Pipe Specifications

Stainless Seamless Steel Pipe Specifications

|

Pipe |

Seamless Stainless Steel Pipe, Stainless Steel Seamless Pipe |

|

Pipe Types |

Seamless Stainless Steel Boiler, Super heater, and Heat-Exchanger Tubes |

|

Schedule |

SCH5, SCH10, SCH20, SCH30, SCH40, STD, SCH80, XS, SCH60, SCH80, SCH120,SCH140, SCH160, XXS |

|

Standard |

EN 10216, BS 3605, JIS 3459, JIS3463, GOS T9941, JIS B2316, BS 3799,ASTM A213, ASTM A312, ASTM A269, ASTM A778, ASTM A789,DIN 17456,DIN 17457,DIN |

|

Pipe Size |

1/8″NB to 24″NB & 1/4″OD TO 24″OD AND 6.35mm to 254mm OD Thickness: 0.6mm to 20mm |

|

Grades |

|

|

Stainless Steel |

ASTM /ASME A/SA 213 / 249 / 269 / 312 / 358 CL. I to V – 304 , 304L , 304H, 309S ,309H , 310S, 310H , 316 , 316TI , 316H , 316 LN , 317 , 317L , 321 , 321H , 347 , 347 H , 904L . |

|

Product Name |

Executive Standard |

Dimension |

Steel Code / Steel Grade |

|

Seamless Austenitic Stainless Steel Pipes |

ASTM A312/A312M, ASME SA312/SA312M |

OD: 1/4″~20″ |

TP304, TP304L, TP304H, TP310, TP310S, TP316, TP316L, TP316Ti, TP317, TP317L, TP321, TP321H, TP347, TP347H |

|

Seamless Austenitic Stainless Steel Tubing for General Service |

ASTM A269, ASME SA269 |

OD: 6.0~50.8mm |

TP304, TP304L, TP304H, TP310, TP310S, TP316, TP316L, TP316Ti, TP317, TP317L, TP321, TP321H, TP347, TP347H |

|

Seamless Austenitic Alloy-Steel Boiler, Super Heater and Heat-Exchanger Tubes |

ASTM A213/A213M, ASME SA213/SA213M |

OD: 6.0~50.8mm |

TP304, TP304L, TP304H, TP310, TP310S, TP316, TP316L, TP316Ti, TP317, TP317L, TP321, TP321H, TP347, TP347H |

|

Seamless Duplex Stainless Steel Tubing for General Service |

ASTM A789 / A789M |

OD: 19.0~60.5mm |

S31803, S32205, S32750 |

|

Seamless Duplex Stainless Steel Pipes |

ASTM A790 / A790M |

OD: 3/4″~10″ |

S31803, S32205, S32750 |

|

Seamless Stainless Steel Mechanical Tubing |

ASTM A511 |

OD: 6.0~50.8mm |

MT304, MT304L, MT304H, MT310, MT310S, MT316, MT316L, MT317, MT317L, MT321, MT321H, MT347 |

|

Seamless Stainless Steel Tubes for Pressure Purposes |

EN 10216, DIN 17456, 17458 |

OD: 6.0~530.0mm |

1.4301, 1.4307, 1.4541, 1.4401, 1.4404, 1.4571, 1.4878, 1.4432, 1.4462 |

GB/T14975, GB/T14976, GB13296, GB9948, GB5310,GB/T21833,GB/T12771,ASTM A312,ASTM A213, ASTMA269, ASTM A789, ASTM A790, ASTM A511, ASTM A376, ASTM A688, JIS 3463, JIS 3459, DIN 2462, DIN 17458, DIN 17456, EN 10297-2, EN 10216-5, GOST 9940, GOST 9941, ASTM A450, ASTM A999, JIS G3459

|

ASTM A213/SA213, ASTM A312/SA312, ASTM A789 |

|||

|

Austenitic |

Ferritic & Martensitic |

Ferritic / Austenitic |

|

|

TP 304 |

TP 316H |

TP 405 |

S32900 |

|

TP 304L |

TP 316Ti |

TP 410 |

S31803 |

|

TP 304H |

TP 321 |

TP 430 |

S32205 |

|

TP 310S |

TP 312H |

|

S32750 |

|

TP 310H |

TP 347 |

|

S31500 |

|

TP 316 |

TP 347H |

|

|

|

TP 316L |

|

|

|

Grades

Grades

|

Standards |

Applicable Code No. |

Steel Grade |

|

ASTM |

A213, A269, A268, A312, A376, A789, A790, B407, B423 |

TP304/L/H/N, TP310/S/H, TP316/L/H/Ti, TP317/L, TP321/H, TP347/H, TP410/S, TP430, S31803, S32205, S32750, S32760, S32304, S31500, TP904/L, S31254, N08800, N08810, N08825 |

|

ASME |

SA213, SA268, SA312, SA376, SA789, SA790, SB407, SB423 |

TP304/L/H/N, TP310/S/H, TP316/L/H/Ti, TP317/L, TP321/H, TP347/H, TP410/S, TP430, S31803, S32205, S32750, S32760, S32304, S31500, TP904/L, S31254, N08800, N08810, N08825 |

|

JIS |

JIS G3459, JIS G3463 |

SUS304TB. SUS304HTB, SUS304LTB, SUS310TB, SUS310STB, |

|

EN & DIN |

EN 10216-5, EN 10297, DIN 17456, DIN 17458 |

1.4301, 1.4307, 1.4541, 1.4401, 1.4404, 1.4571, |

Benefits of Seamless SS Pipe

Benefits of Seamless SS Pipe

Seamless SS Pipe is resistant to rust and other corrosive attack. It is heat-resistant for high-performance and high-temperature use

Applications & Uses of Stainless Steel Seamless Pipe

Applications & Uses of Stainless Steel Seamless Pipe

Stainless Steel Seamless Pipe can resist high temperatures for cleanliness and maintain the purity of materials which contact stainless steel directly. SS seamless tube can be used in the following fileds:

- Chemical plants

- Aviation fields

- Marine equipment

- Cryogenic transportation

- Medical & architectural industries

Stainless Steel Pipe Test

Stainless Steel Pipe Test

Chemical Component Analysis, Mechanical Properties (Ultimate tensile strength, Yield strength, Elongation),

Technical Properties (Flattening Test, Bending Test, Blow Test, Impact Test), Exterior Size Inspection, Hydrostatic Test,eddy -currect test.

Packing and Shipping

Packing and Shipping

Packing Details: In bundles with waterproof material, in wooden cases or be required

Container Size:

20ft GP:5898mm(Length)x2352mm(Width)x2393mm(High) 24-26CBM

40ft GP:12032mm(Length)x2352mm(Width)x2393mm(High) 54CBM

40ft HC:12032mm(Length)x2352mm(Width)x2698mm(High) 68CBM

SS Pipe Supplier in China - Mechanical Properties

SS Pipe Supplier in China - Mechanical Properties|

Material Designation |

Tensile Strength Minimum |

Yield Strength Minimum |

Elongation in 2 Inches Minimum |

|

Standard 300 Series |

75,000 psi |

30,000 psi |

35% |

|

300 Series L Grades |

70,000 psi |

25,000 psi |

35% |

|

300 Series H Grades |

75,000 psi |

30,000 psi |

35% |

Seamless Stainless Steel Tubing Size Chart

Seamless Stainless Steel Tubing Size Chart

|

Material Designation |

Tensile Strength Minimum |

Yield Strength Minimum |

Elongation in 2 Inches Minimum |

|

Standard 300 Series |

75,000 psi |

30,000 psi |

35% |

|

300 Series L Grades |

70,000 psi |

25,000 psi |

35% |

|

300 Series H Grades |

75,000 psi |

30,000 psi |

35% |

Chemical Composition for Stainless Seamless Steel Pipe(%)

Chemical Composition for Stainless Seamless Steel Pipe(%)

| Grade | UNS # | Content % by weight | |||||||

| Carbon | Manganese | Phosphorus | Sulfur | Silicon | Chromium | Nickel | Molybdenum | ||

| TP304l | S30400 | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 18 – 20 | 8 – 11 | x |

| TP304L | S30403 | 0.035 | 2.00 | 0.045 | 0.030 | 1.00 | 18 – 20 | 8 – 13 | x |

| TP316 | S31600 | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 16 – 18 | 10 – 14 | 2 – 3 |

| TP316L | S31603 | 0.035 | 2.00 | 0.045 | 0.030 | 1.00 | 16 – 18 | 10 – 14 | 2 – 3 |

HuNan Province

+86-731-85648266

LiaoNing Province

+86-731-85648266

HeBei Province

+86-731-85648299

jiangsu Province

+86-731-85648299

TianJin City

Singapore