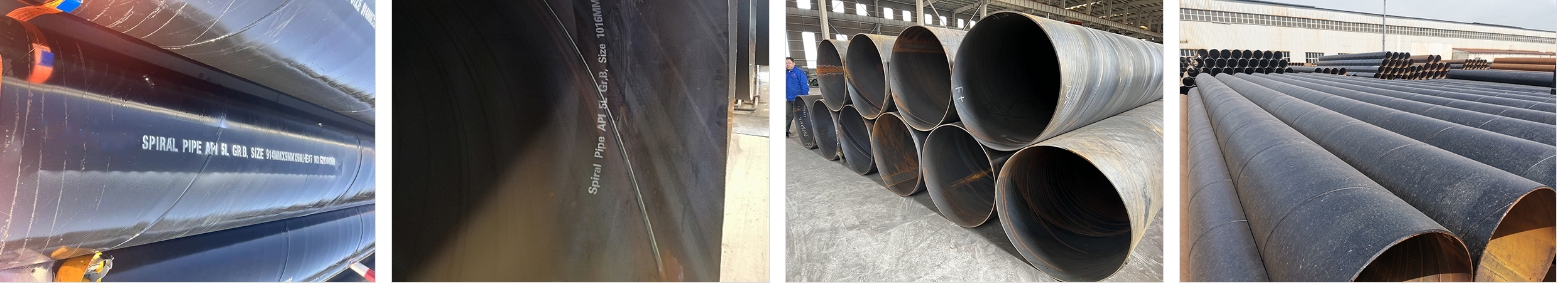

| Product: | SSAW Pipe,Spirally Submerged Arc Welding Pipe, Sprial Steel Pipe |

| Application: | Used for Oil/Gas/Water transmission,Construction & Structure Parts |

| Size: | OD: 219mm-4064mm |

| WT: 3.2-40mm | |

| LENGTH: 5.8/6/11.8/12m | |

| Pipe Standard: | API 5L PSL1/PSL2 Gr.A,Gr.B,X42,X46,X52,X56,X60,X65,X70 |

| ASTM A53 ASTM 139 | |

| ASTM A252 Grade 1/2/3 | |

| AN/NZS 1163 | |

| EN10219-1 EN10217-1 EN10208 |

SSAW Steel Pipe Introduction

SSAW Steel Pipe Introduction

|

Product: |

SSAW Pipe,Spirally Submerged Arc Welding Pipe, Sprial Steel Pipe |

|

Application: |

Used for Oil/Gas/Water transmission,Construction & Structure Parts |

|

Size: |

OD: 219mm-4064mm |

|

WT: 3.2-40mm |

|

|

LENGTH: 5.8/6/11.8/12m |

|

|

Pipe Standard: |

API 5L PSL1/PSL2 Gr.A,Gr.B,X42,X46,X52,X56,X60,X65,X70 |

|

ASTM A53 ASTM 139 |

|

|

ASTM A252 Grade 1/2/3 |

|

|

AN/NZS 1163 |

|

|

EN10219-1 EN10217-1 EN10208 |

Specification of SSAW Pipe

|

OUT DIAMETER |

WALL THICKNESS (MM) |

|||||||||||||||||||

|

mm |

6 |

7 |

8 |

9 |

10 |

11 |

12 |

13 |

14 |

15 |

16 |

17 |

18 |

19 |

20 |

21 |

22 |

23 |

24 |

25 |

|

219.1 |

. |

. |

. |

. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

273 |

. |

. |

. |

. |

. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

323.9 |

. |

. |

. |

. |

. |

. |

. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

325 |

. |

. |

. |

. |

. |

. |

. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

355.6 |

. |

. |

. |

. |

. |

. |

. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

377 |

. |

. |

. |

. |

. |

. |

. |

. |

|

|

|

|

|

|

|

|

|

|

|

|

|

406.4 |

. |

. |

. |

. |

. |

. |

. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

426 |

. |

. |

. |

. |

. |

. |

. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

457 |

. |

. |

. |

. |

. |

. |

. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

478 |

. |

. |

. |

. |

. |

. |

. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

508 |

. |

. |

. |

. |

. |

. |

. |

|

. |

|

|

|

|

|

|

|

|

|

|

|

|

529 |

. |

. |

. |

. |

. |

. |

. |

|

. |

|

|

|

|

|

|

|

|

|

|

|

|

630 |

. |

. |

. |

. |

. |

. |

. |

|

. |

. |

|

|

|

|

|

|

|

|

|

|

|

711 |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

|

|

|

|

|

|

|

|

|

|

720 |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

|

|

|

|

|

|

|

|

|

|

813 |

|

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

|

|

|

|

|

|

|

|

820 |

|

. |

. |

. |

|

. |

. |

. |

. |

. |

. |

. |

. |

|

|

|

|

|

|

|

|

920 |

|

|

. |

. |

|

. |

. |

. |

. |

. |

. |

. |

. |

|

|

|

|

|

|

|

|

1020 |

|

|

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

|

|

|

|

|

|

1220 |

|

|

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

|

|

|

|

|

|

1420 |

|

|

|

. |

. |

. |

. |

. |

. |

. |

|

. |

. |

. |

. |

|

|

|

|

|

|

1620 |

|

|

|

|

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

|

|

|

|

|

|

1820 |

|

|

|

|

|

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

|

|

|

|

|

|

2020 |

|

|

|

|

|

|

. |

. |

. |

. |

. |

. |

. |

. |

. |

|

|

|

|

|

|

2220 |

|

|

|

|

|

|

|

. |

. |

. |

. |

. |

. |

. |

. |

|

|

|

|

|

|

2500 |

|

|

|

|

|

|

|

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

|

2540 |

|

|

|

|

|

|

|

|

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

|

3500 |

|

|

|

|

|

|

|

|

|

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

Standard and Classfication of SSAW Steel Pipe

Standard and Classfication of SSAW Steel Pipe

|

CLASSFICATION |

STANDARD |

MAIN PRODUCTS |

|

Steel Pipe for Fluid Service |

GB/T 14291 |

Welded pipe for mine fluid sevice |

|

GB/T 3091 |

Welded pipe for low pressure fluid service |

|

|

SY/T 5037 |

Spirally submerged arc welded steel pipe for pipelines for low pressure fluid service |

|

|

ASTM A53 |

Black and hot-hipped galvanized welded and seamless steel pipe |

|

|

BS EN10217-2 |

Welded steel tybes for pressure purposes - delivery technical conditions - part2: Electric welded non- alloy and alloy steel tubes with specified elevated temperature properties |

|

|

BS EN10217-5 |

Welded steel tybes for pressure purposes - delivery technical conditions - part5: submerged arc welded non-alloy and alloy steel tubes with specified elevated temperature properties |

|

|

Steel Pipe for Ordinary Structure |

GB/T 13793 |

Longitudinally electric resistance welded steel pipe |

|

SY/T 5040 |

Spirally submerged arc welded steel pipe piles |

|

|

ASTM A252 |

Welded and seamless steel pipe piles |

|

|

BS EN10219-1 |

Cold formed welded structural hollow sections of non-alloy and fine grain steels - part1: Technical delivert conditions |

|

|

BS EN10219-2 |

Cold formed welded structural hollow sections of non-alloy and fine grain steels - part2: tolerances dimmsions and sectional properties |

|

|

Line Pipe |

GB/T 9711.1 |

Steel pipe for pipeline transportation system of petroleum and natural gas industries(Class A steel pipe) |

|

GB/T 9711.2 |

Steel pipe for pipeline transportation system of petroleum and natural gas industries(Class B steel pipe) |

|

|

PSL1/2 |

Line pipe |

|

|

Casing |

API 5CT/ ISO 11960 PSL1 |

Steel pipe for use as casing or tubing for wells of petroleum and natural gas industries |

Coating Standard:

Coating Standard:

· ANSI/AWWA C104/A21.4 American National Standard for Cement-Mortar Lining for ductile-iron Pipe and Fittings for water

· DIN 30670 Polyethylene coatings of steel and fittings

Packing: Plastic plugs in both ends, Hexagonal bundles of max. 2,000kg with several steel strips, Two tags on each bundle, Wrapped in waterproof paper, PVC sleeve, and sackcloth with several steel strips, Plastic caps.

Material of HSAW Pipe

Material of HSAW Pipe

|

Uses |

Standard |

|

Steel Pipe for Fluid Service |

GB/T 14291 |

|

GB/T 3091 |

|

|

SY/T 5037 |

|

|

ATSM A53 |

|

|

BS EN10217-2 |

|

|

BS EN10217-5 |

|

|

Steel Pipe for Ordinary Structure |

GB/T 13793 |

|

SY/T 5040 |

|

|

ASTM A252 |

|

|

BS EN10219-1 |

|

|

BS EN10219-2 |

|

|

Line Pipe |

GB/T 9711.1 |

|

GB/T 9711.2 |

|

|

API 5L PSL1/2 |

|

|

Casing |

API 5CT/ ISO 11960 PSL1 |

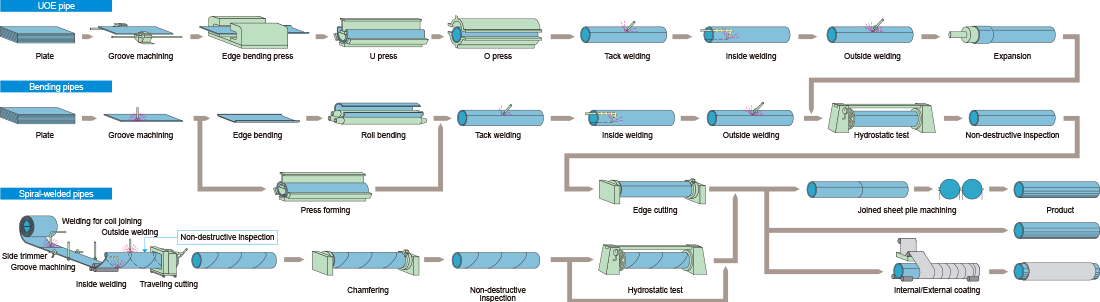

SSAW Pipe (HSAW Pipe) Manufacturing Process

Spiral Welded Pipe production by submerged arc method is based on using tandem welding technique for joining inside and outside coil edges, which have been trimmed and beveled by carbide milling for high quality weld structure.

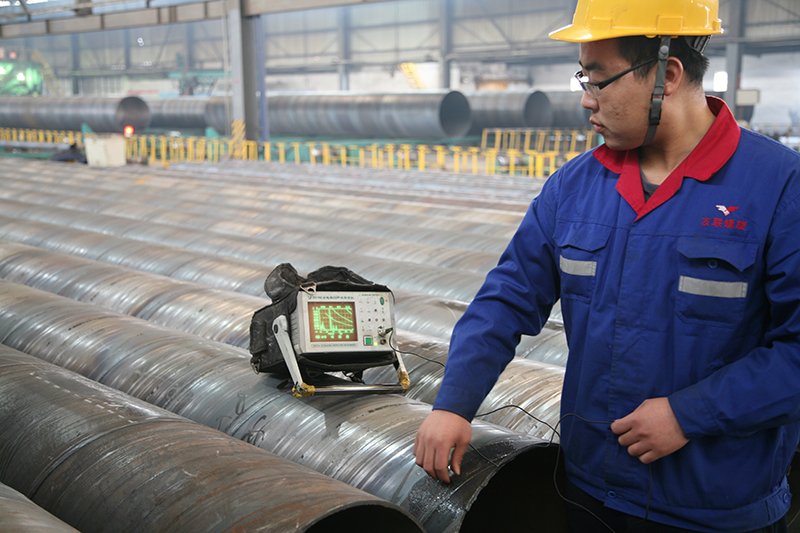

- Chemical Component Analysis

- Mechanical Properties

- Elongation, Yield Strength, Ultimate Tensile Strength

- Technical Properties

- DWT Test, Impact Test, Blow Test, Flattening Test

- X-Ray Test

SSAW Pipe Tolerance of Outside Diameter and Wall Thickness

SSAW Pipe Tolerance of Outside Diameter and Wall Thickness

|

STANDARD |

TOLERANCE OF PIPE BODY |

TOLERANCE OF PIPE END |

TOLERANCE OF WALL THICKNESS |

|||

|

OUT DIAMETER |

TOLERANCE |

OUT DIAMETER |

TOLERANCE |

|||

|

GB/T3091 |

OD≤48.3mm |

≤±0.5 |

OD≤48.3mm |

- |

≤±10% |

|

|

48.3 |

≤±1.0% |

48.3 |

- |

|||

|

273.1 |

≤±0.75% |

273.1 |

-0.8~+2.4 |

|||

|

OD>508mm |

≤±1.0% |

OD>508mm |

-0.8~+3.2 |

|||

|

GB/T9711.1 |

OD≤48.3mm |

-0.79~+0.41 |

- |

- |

OD≤73 |

-12.5%~+20% |

|

60.3 |

≤±0.75% |

OD≤273.1mm |

-0.4~+1.59 |

88.9≤OD≤457 |

-12.5%~+15% |

|

|

508 |

≤±1.0% |

OD≥323.9 |

-0.79~+2.38 |

OD≥508 |

-10.0%~+17.5% |

|

|

OD>941mm |

≤±1.0% |

- |

- |

- |

- |

|

|

GB/T9711.2 |

60 |

±0.75%D~±3mm |

60 |

±0.5%D~±1.6mm |

4mm |

±12.5%T~±15.0%T |

|

610 |

±0.5%D~±4mm |

610 |

±0.5%D~±1.6mm |

WT≥25mm |

-3.00mm~+3.75mm |

|

|

OD>1430mm |

- |

OD>1430mm |

- |

- |

-10.0%~+17.5% |

|

|

SY/T5037 |

OD<508mm |

≤±0.75% |

OD<508mm |

≤±0.75% |

OD<508mm |

≤±12.5% |

|

OD≥508mm |

≤±1.00% |

OD≥508mm |

≤±0.50% |

OD≥508mm |

≤±10.0% |

|

|

API 5L PSL1/PSL2 |

OD<60.3 |

-0.8mm~+0.4mm |

OD≤168.3 |

-0.4mm~+1.6mm |

WT≤5.0 |

≤±0.5 |

|

60.3≤OD≤168.3 |

≤±0.75% |

168.3 |

≤±1.6mm |

5.0 |

≤±0.1T |

|

|

168.3 |

≤±0.75% |

610 |

≤±1.6mm |

T≥15.0 |

≤±1.5 |

|

|

610 |

≤±4.0mm |

OD>1422 |

- |

- |

- |

|

|

OD>1422 |

- |

- |

- |

- |

- |

|

|

API 5CT |

OD<114.3 |

≤±0.79mm |

OD<114.3 |

≤±0.79mm |

≤-12.5% |

|

|

OD≥114.3 |

-0.5%~1.0% |

OD≥114.3 |

-0.5%~1.0% |

≤-12.5% |

||

|

ASTM A53 |

≤±1.0% |

≤±1.0% |

≤-12.5% |

|||

|

ASTM A252 |

≤±1.0% |

≤±1.0% |

≤-12.5% |

|||

Chemical Analysis and Mechanical Properties of HSAW Pipe

Chemical Analysis and Mechanical Properties of HSAW Pipe

|

Standard |

Grade |

Chemical Composition(max)% |

Mechanical Properties(min) |

|||||

|

C |

Si |

Mn |

P |

S |

Tensile Strength(Mpa) |

Yield Strength(Mpa) |

||

|

API 5CT |

h40 |

- |

- |

- |

- |

0.030 |

417 |

417 |

|

J55 |

- |

- |

- |

- |

0.030 |

517 |

517 |

|

|

K55 |

- |

- |

- |

- |

0.300 |

655 |

655 |

|

|

API 5L PSL1 |

A |

0.22 |

- |

0.90 |

0.030 |

0.030 |

335 |

335 |

|

B |

0.26 |

- |

1.20 |

0.030 |

0.030 |

415 |

415 |

|

|

X42 |

0.26 |

- |

1.30 |

0.030 |

0.030 |

415 |

415 |

|

|

X46 |

0.26 |

- |

1.40 |

0.030 |

0.030 |

435 |

435 |

|

|

X52 |

0.26 |

- |

1.40 |

0.030 |

0.030 |

460 |

460 |

|

|

X56 |

0.26 |

- |

1.40 |

0.030 |

0.030 |

490 |

490 |

|

|

X60 |

0.26 |

- |

1.40 |

0.030 |

0.030 |

520 |

520 |

|

|

X65 |

0.26 |

- |

1.45 |

0.030 |

0.030 |

535 |

535 |

|

|

X70 |

0.26 |

- |

1.65 |

0.030 |

0.030 |

570 |

570 |

|

|

API 5L PSL2 |

B |

0.22 |

0.45 |

1.20 |

0.025 |

0.015 |

415 |

415 |

|

X42 |

0.22 |

0.45 |

1.30 |

0.025 |

0.015 |

415 |

415 |

|

|

X46 |

0.22 |

0.45 |

1.40 |

0.025 |

0.015 |

435 |

435 |

|

|

X52 |

0.22 |

0.45 |

1.40 |

0.025 |

0.015 |

460 |

460 |

|

|

X56 |

0.22 |

0.45 |

1.40 |

0.025 |

0.015 |

490 |

490 |

|

|

X60 |

0.12 |

0.45 |

1.60 |

0.025 |

0.015 |

520 |

520 |

|

|

X65 |

0.12 |

0.45 |

1.60 |

0.025 |

0.015 |

535 |

535 |

|

|

X70 |

0.12 |

0.45 |

1.70 |

0.025 |

0.015 |

570 |

570 |

|

|

X80 |

0.12 |

0.45 |

1.85 |

0.025 |

0.015 |

625 |

625 |

|

|

ASTM A53 |

A |

0.25 |

0.10 |

0.95 |

0.050 |

0.045 |

330 |

330 |

|

B |

0.30 |

0.10 |

1.20 |

0.050 |

0.045 |

415 |

415 |

|

|

ASTM A252 |

1 |

- |

- |

- |

0.050 |

- |

345 |

345 |

|

2 |

- |

- |

- |

0.050 |

- |

414 |

414 |

|

|

3 |

- |

- |

- |

0.050 |

- |

455 |

455 |

|

|

EN10217-1 |

P195TR1 |

0.13 |

0.35 |

0.70 |

0.025 |

0.020 |

320 |

320 |

|

P195TR2 |

0.13 |

0.35 |

0.70 |

0.025 |

0.020 |

320 |

320 |

|

|

P235TR1 |

0.16 |

0.35 |

1.20 |

0.025 |

0.020 |

360 |

360 |

|

|

P235TR2 |

0.16 |

0.35 |

1.20 |

0.025 |

0.020 |

360 |

360 |

|

|

P265TR1 |

0.20 |

0.40 |

1.40 |

0.025 |

0.020 |

410 |

410 |

|

|

P265TR2 |

0.20 |

0.40 |

1.40 |

0.025 |

0.020 |

410 |

410 |

|

|

EN10217-2 |

P195GH |

0.13 |

0.35 |

0.70 |

0.025 |

0.020 |

320 |

320 |

|

P235GH |

0.16 |

0.35 |

1.20 |

0.025 |

0.020 |

360 |

360 |

|

|

P265GH |

0.20 |

0.40 |

1.40 |

0.025 |

0.020 |

410 |

410 |

|

|

EN10217-5 |

P235GH |

0.16 |

0.35 |

1.20 |

0.025 |

0.020 |

360 |

360 |

|

P265GH |

0.20 |

0.40 |

1.40 |

0.025 |

0.020 |

410 |

410 |

|

|

EN10219-1 |

S235JRH |

0.17 |

- |

1.40 |

0.040 |

0.040 |

360 |

360 |

|

S275JOH |

0.20 |

- |

1.50 |

0.035 |

0.035 |

410 |

410 |

|

|

S275J2H |

0.20 |

- |

1.50 |

0.030 |

0.030 |

410 |

410 |

|

|

S355JOH |

0.22 |

0.55 |

1.60 |

0.035 |

0.035 |

470 |

470 |

|

|

S355J2H |

0.22 |

0.55 |

1.60 |

0.030 |

0.030 |

470 |

470 |

|

|

S355K2H |

0.22 |

0.55 |

1.60 |

0.030 |

0.030 |

470 |

470 |

|

HuNan Province

+86-731-85648266

LiaoNing Province

+86-731-85648266

HeBei Province

+86-731-85648299

jiangsu Province

+86-731-85648299

TianJin City

Singapore