|

|

|

Type |

Momentof inertia |

Sectionmodulus |

Unit mass |

Maximumlength |

Grade |

|||||||||

|

|

|

|

|

|

|

|

JIS A 5523 |

JIS A 5528 |

KS F4604 |

EN10248 |

ASTM |

|||||

|

|

|

|

I (cm4/m) |

Z(cm³/m) |

W (kg/m2) |

L (m) |

SYW295 |

SYW390 |

SYW430 |

SY295 |

SY390 |

SY300 |

S355GP |

S430GP |

A572 Gr.50 |

A992 Gr.50 |

|

Hat-type sheet piles |

Hat w= 900 mm |

NS-SP-10H |

10,500 |

902 |

96 |

30*2 |

✓ |

✓ |

✓ *4 |

– |

– |

– |

–*2 |

–*4 |

✓ *2 |

– |

|

|

|

NS-SP-25H |

24,400 |

1,610 |

126 |

30*2 |

✓ |

✓ *1 |

✓ *1 |

– |

– |

– |

–*2 |

–*4 |

✓ *2 |

– |

|

|

|

NS-SP-45H |

45,000 |

2,450 |

163 |

24*1*2 |

✓ |

✓ |

✓ *1 |

– |

– |

– |

–*2 |

–*2 |

–*4 |

– |

|

|

|

NS-SP-50H |

51,100 |

2,760 |

186 |

23.5*1*2 |

✓ *1 |

✓ *1 |

✓ *1 |

– |

– |

– |

–*2 |

–*2 |

–*4 |

– |

|

|

Hat+H w= 900 mm |

NS-SP-10H+HY NS-SP-25H+HY |

87,800 to 1,316,000 |

2,320 to 19,970 |

169 to 514 |

30*2 |

Please refer to “NS-SP-10H"and “NS-SP-25H". H-shapes is also available JIS, ASTM and BS.*2 |

|||||||||

|

|

Hat + (Hat+H)w=900 mm |

NS-SP-10H+HY |

49,100 to 273,000 |

1,290 to 4,940 |

132 to 210 |

30*2 |

|

|||||||||

|

Straightweb-type sheet piles |

Straight webw= 500 mm |

NS-SP-FL |

396 |

89 |

123 |

38*2 |

✓ |

✓ |

–*4 |

✓ |

✓ |

– |

✓ *2*3 |

–*4 |

✓ *2 |

✓ |

|

|

|

NS-SP-FXL |

570 |

121 |

154 |

38*2 |

✓ |

✓ |

✓ |

✓ |

✓ |

– |

✓ *2 |

✓ *2 |

✓ *2 |

✓ |

|

U-type sheet piles |

U-type w= 600 mm |

NS-SP-Ⅱw |

13,000 |

1,000 |

103 |

30*2 |

✓ |

✓ |

–*4 |

✓ |

✓ |

✓ |

✓ *2 |

–*4 |

✓ *2 |

– |

|

|

|

NS-SP-Ⅲw |

32,400 |

1,800 |

136 |

30*2 |

✓ |

✓ |

–*4 |

✓ |

✓ |

✓ |

✓ *2 |

–*4 |

✓ *2 |

– |

|

|

|

NS-SP-Ⅳw |

56,700 |

2,700 |

177 |

30*2 |

✓ |

✓ |

– |

✓ |

✓ |

✓ |

✓ *2 |

–*4 |

✓ *2 |

– |

|

|

w= 500 mm |

NS-SP-VL |

63,000 |

3,150 |

210 |

30*2 |

✓ |

✓ |

– |

✓ |

✓ |

✓ |

✓ *2 |

–*4 |

✓ *2 |

– |

|

|

|

NS-SP-VIL |

86,000 |

3,820 |

240 |

30*2 |

✓ |

✓ |

– |

✓ |

✓ |

✓ |

✓ *2 |

–*4 |

✓ *2 |

– |

|

|

w= 400 mm |

NS-SP-Ⅱ |

8,740 |

874 |

120 |

25*2 |

✓ |

–*4 |

✓ *4 |

✓ |

–*4 |

– |

–*4 |

–*4 |

– |

– |

|

|

|

NS-SP-Ⅲ |

16,800 |

1,340 |

150 |

30*2 |

✓ |

✓ |

✓ *1 |

✓ |

✓ |

✓ |

✓ *1*2 |

✓ *1*2 |

✓ *2 |

– |

|

|

|

NS-SP-ⅢA |

22,800 |

1,520 |

146 |

30*2 |

– |

✓ |

– |

✓ |

– |

✓ |

– |

– |

– |

– |

|

|

|

NS-SP-Ⅳ |

38,600 |

2,270 |

190 |

30*2 |

✓ |

✓ |

✓ |

✓ |

✓ |

✓ |

✓ *1*2 |

✓ *1*2 |

✓ *2 |

– |

|

NS-SP-J |

NS-SP-J w= 600 mm |

NS-SP-J |

12,090 |

1,175 |

145 |

30*2 |

✓ |

✓ |

– |

✓ |

✓ |

✓ |

✓ *4 |

–*4 |

✓ *2 |

– |

*1) Please contact us detail in advance to order.

*2) Tolerance of dimension based on JIS standard (refer to page 11)

*3) Mechanical property of elongation based on JIS standard (refer to page 11)

*4) Please contact us availability.

Applications of Steel Sheet Pile:

Applications of Steel Sheet Pile:

Bulkheads–from small retaining walls for private marinas to large dry docks, ports, and other infrastructure projects

Cofferdams–temporary, in water or on land, to permit excavation for and construction of permanent works

Cut-off Walls–in connection with earth or concrete dams or dikes to retard seepage

Environmental Barrier Walls–for contaminant containment purposes

Temporary and Permanent Retaining Walls

Seawalls, Flood Walls, Dikes, Jetties, Groins

Navigation Lock Walls and other large navigation structures

Mooring and Turning Cells, Dolphins

Barge Docks–consisting of individual cellular structures

Bridge Protection Cells–to protect bridge piers from shipping collisions.

Bridge Abutments

Temporary or Permanent Below Grade Shoring–for basements and parking structures

Artificial Islands

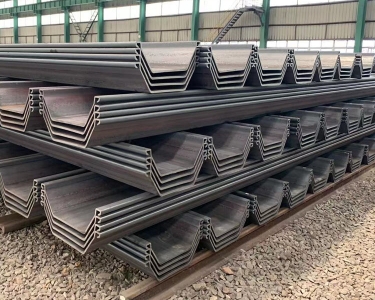

Types of Steel Sheet Pile:

Types of Steel Sheet Pile:

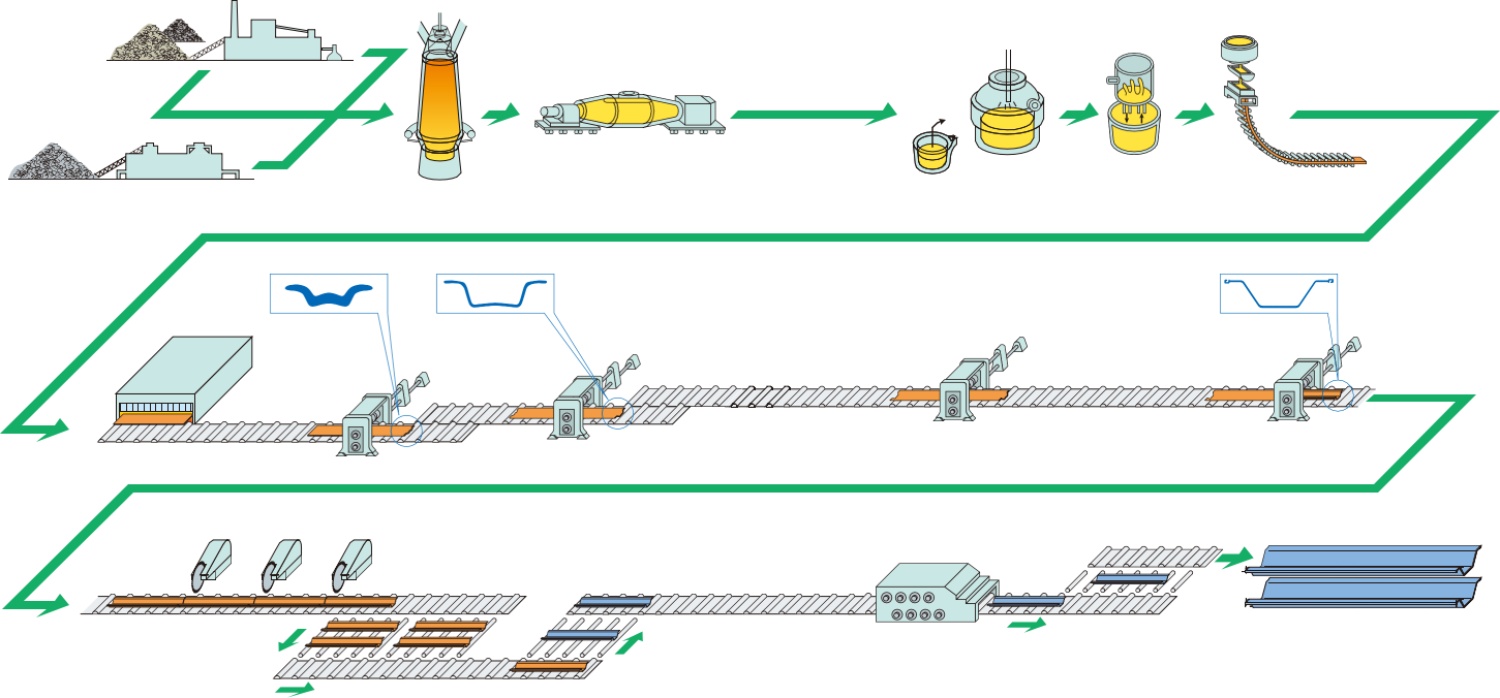

Steel sheet piling is manufactured in three basic configurations: “Z”, “U” and “straight” (flat). Historically, such shapes have been hot-rolled products produced at structural mills. Like other shapes such as beams or channels, the steel is heated in a furnace and then passes through a series of rolls to form the final shape and the interlock, which allows the sheet piles to be threaded together. Some manufacturer’s use a cold-forming process in which steel coil is rolled at room temperature into the final sheet pile shape. Cold formed sheet piles have hook and grip interlocks.

Grades of Steel Sheet Piling:

Grades of Steel Sheet Piling:

Sheet piling is specified by reference to the ASTM standard. The basic grade is ASTM A572 Gr 50, with many manufacturers producing ASTM A572 Gr 60 as the new standard.

Additional grades of steel for piling have been developed for possible use where corrosion is a consideration. ASTM A690 and A588 are 50 ksi (345 MPa) yield steels of a formulation which has demonstrated increased life. ASTM A690 has been shown to reduce the corrosion rate in the splash zone by 2 to 3 times. A588, also known as weathering steel, is resistant to corrosion in the atmospheric zone.

There are other proprietary steel grades, such as AMLoCor®, which has been shown to reduce the corrosion rate in the permanent immersion zone by up to 5 times.

The steel sheet pilegenerally has the material inspection and the appearance inspection, in order to correct the steel sheet pile which is not required, so as to reduce the difficulty in piling process.

(1) appearance inspection: including surface defects,length, width, thickness, end to rectangle ratio, flatness and the shape of the lock mouth, etc.. Need attention:

A, have influence on the welding pieces into the steel sheet pile should be cut off; B, cut hole and section defect should be reinforced:

The actual section thickness should be measured if C and steel plate piles are seriously corroded. In principle, the

Quality inspection of all steel sheet piles should be carried out

(2) material test: the chemical composition and mechanical properties of steel sheet pile base material are comprehensively tested.Including the chemical composition analysis of steel, tensile and bending test of

Components,locking strength test and elongation test.At least one tensile and bending test is carried out for each specification of steel sheet pile: two steel specimens per 20-50t weight should be tested.

| Item | ASTM A6 |

| Length | + 125 mm |

| -0 mm | |

| Mass tolerance | ±2.5% |

Please contact us in case above tolerances are applied.

JIS A 5523 : 2012 Weldable hot-rolled steel sheet piles

JIS A 5523 : 2012 Weldable hot-rolled steel sheet piles

JIS A 5528 : 2012 Hot-rolled steel sheet piles

Chemical composition of the ladle analysis

|

Classification |

Grade |

Chemical composition(%) |

Ceq(. %) |

|||||

|

C |

Si |

Mn |

P |

S |

N |

Ceq. |

||

|

Weldable hot rolledsteel sheet piles |

SYW295 |

0.18max. |

0.55max. |

1.50max. |

0.040max. |

0.040max. |

0.0060max. |

0.44max. 0.45max. |

|

SYW390 |

||||||||

|

Hot rolled steel sheet piles |

SY295 |

ー |

ー |

ー |

0.040max. |

0.040max. |

ー |

ー |

|

SY390 |

||||||||

Note: Ceq.=C+Mn/6+Si/24+Ni/40+Cr/5+Mo/4+V/14

Mechanical properties

|

Standard |

Classification symbol |

Yield point N/mm² |

TensileStrengthN/mm² |

TestPiece |

Elongation % |

Charpy absorbed energy, J |

Type and direction of test piece |

|||

|

Testtemperature (℃) |

Standard size test specimen |

Sub-size test specimen |

||||||||

|

10×10mm |

10×7.5mm |

10×5mm |

||||||||

|

Weldable hot rolledsteel sheet piles JIS A 5523 |

SYW295 |

295min. |

450min. |

No.1A |

18min. |

0 |

43min. |

32min. |

22min. |

V notch in rolling direction |

|

No.14B |

24min. |

|||||||||

|

SYW390 |

390min. |

490min. |

No.1A |

16min. |

||||||

|

No.14B |

20min. |

|||||||||

|

Hot rolled steel sheet piles JIS A 5528 |

SY295 |

295min. |

450min. |

No.1A |

18min. |

ー |

ー |

ー |

ー |

ー |

|

No.14B |

24min. |

|||||||||

|

SY390 |

390min. |

490min. |

No.1A |

16min. |

||||||

|

No.14B |

20min. |

|||||||||

Note: Chemical composition and mechanical properties conform to JIS A 5523-2012 or JIS A 5528-2012 .

N is shown by total in accordance with section 5. Note 2 of JIS A 5523-2012.

BS EN 10248-1 : 1996

BS EN 10248-1 : 1996

Hot-rolled sheet piling of non-alloy steel Part 1. Technical delivery conditions

Chemical composition of the ladle analysis

|

Steel name |

Chemical composition % max1) |

|||||

|

C |

Mn |

Si |

P |

S |

N1) |

|

|

S355GP |

0.24 |

1.60 |

0.55 |

0.045 |

0.045 |

0.009 |

|

S430GP |

||||||

Mechanical properties

|

Steel name |

Minimum yield strength (N/mm2) |

Minimumtensile strength (N/mm²)1) |

Minimum elongation on a gauge length of L0 = 5.65 S0 A% |

|

S355GP |

355 |

480 |

22 |

|

S430GP |

430 |

510 |

19 |

1) See the specific limitation in the standard.

* Please contact us in advance.

ASTM A572M / A572-12

ASTM A572M / A572-12

High-strength low-alloy columbium-vanadium structural steel

Chemical composition of the ladle analysis

|

Grade |

Chemical composition % max |

||||

|

C |

Mn |

Si |

P |

S |

|

|

50 |

0.23 |

1.351) |

0.40 |

0.04 |

0.05 |

1) See the specific limitation in the standard.

Mechanical properties

|

Grade |

Minimum yield strength |

Minimum tensile strength |

Minimum elongation(%) |

|

50 |

50Ksi (345MPa) |

65Ksi (450MPa) |

In 8 in. (200 mm):18 In 2 in. (50 mm):21 |

* Please contact us in advance

HuNan Province

+86-731-85648266

LiaoNing Province

+86-731-85648266

HeBei Province

+86-731-85648299

jiangsu Province

+86-731-85648299

TianJin City

Singapore