| Size: | OD: DN15- DN2000 (1/2''- 80'') |

| Type: welding neck, slip on, blind, socket welding, threaded, lap-joint | |

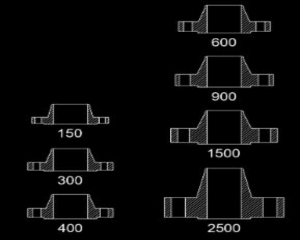

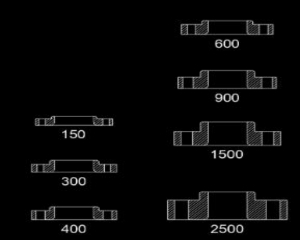

| Pressure: 150#, 300#, 600#,900#,1500#, 2500# | |

| Material: | carbon steel A105, C22.8, S235, S235JR, P235GH,SS400,37.2 |

| Stainless Steel 304/L,316/L,321,310S,347H,1.4301, 1.4404 | |

| ASTM A234 WP1/5/9/11/12/22/91 | |

| Duplex stainless steel: UNS31803, SAF2205, UNS32205, UNS31500 | |

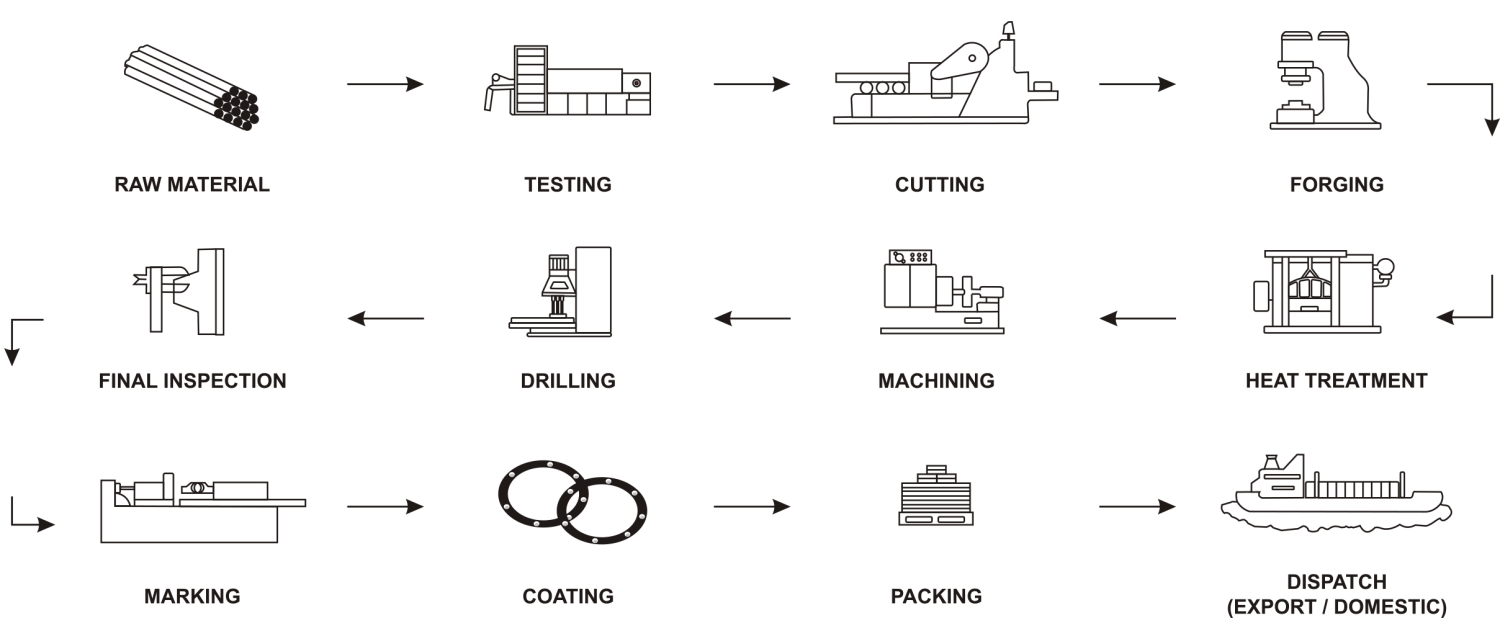

| Coating: | Rust-proof oil, cold and hot galvanize |

| Packing | sea worthy plywooden case, wooden pallet |

Size:

OD: DN15- DN2000 (1/2''- 80'')

Type: welding neck, slip on, blind, socket welding, threaded, lap-joint

Pressure: 150#, 300#, 600#,900#,1500#, 2500#

Material:

carbon steel A105, C22.8, S235, S235JR, P235GH,SS400,37.2

Stainless Steel 304/L,316/L,321,310S,347H,1.4301, 1.4404

ASTM A234 WP1/5/9/11/12/22/91

Duplex stainless steel: UNS31803, SAF2205, UNS32205, UNS31500

Coating:

Rust-proof oil, cold and hot galvanize

Packing

sea worthy plywooden case, wooden pallet

Size:

OD: DN15- DN2000 (1/2''- 80'')

Pipe Fitting Flange Introduction

Pipe Fitting Flange Introduction

Common Steel Tube Flange Types:

Common Steel Tube Flange Types:

Blind flange

Weld neck flange

Socket weld flange

Slip on flange

Thread flange

Raised Face Flange

Lap Joint Flange

Blind flange

|

Product Name: |

Blind flange |

|

Material: |

Carbon Steel Flange: 20#, Q235, A105, Stainless Steel Flange: F304 F304L |

|

Surface Treatment: |

Anti-rust Oil, Transparent / Yellow / Black Anti-rust Paint, Zinc / Hot dipped Galvanized |

|

Size: |

15A- 2000A, 1/2"-78" |

|

Class: |

Class400, Class600, Class900, Class1500, Class2500 |

Weld neck flange

|

Product Name: |

Weld neck flange |

|

Material: |

Stainless steel, Carbon steel, Alloy steel |

|

Standard: |

ASTM, ASME, JIS, DIN, BS |

|

Size: |

1/2 - 24" |

|

Class: |

Class150, Class300, Class400, Class600, Class900, Class1500, Class2500 |

Socket weld flange

|

Product Name: |

Socket weld flange |

|

Material: |

Stainless steel, Carbon steel, Alloy steel |

|

Standard: |

ASTM, ASME, JIS, DIN, GB, BS |

|

Size: |

1/2 - 24" |

|

Class: |

Class150, Class300, Class400, Class600, Class900, Class1500, Class2500 |

Slip on flanges

|

Product Name: |

Slip On Flange |

|

Material: |

Carbon Steel Flange: 20#, Q235, |

|

Standard: |

ASTM, ASME, JIS, DIN, GB, BS |

|

Size: |

15A- 2000A, 1/2"-78" |

|

Class: |

Class150, Class300, Class400, Class600, Class900, Class1500, Class2500 |

Threaded flange

|

Product Name: |

Threaded flange |

|

Material: |

Stainless steel, Carbon steel, Alloy steel, Nickel alloy, Copper alloy, Copper, Brass and Bronze |

|

Standard: |

ASTM, ASME, JIS, DIN, GB, BS |

|

Size: |

1/2"NB TO 60"NB IN |

|

Class: |

Class150, Class300, Class400, Class600, Class900, Class1500, Class2500 |

Lap joint flange

A lap joint flange, abbreviated as LJF, is a flange that consists of two parts, a stub end and the backing flange.

In general, the thickness of the hub is between ¼” to 3/8”.

Raised face flange

the most common type of flange facing is the raised face flange, abbreviated as RF. It is used in almost all applications in high and low pressures and temperatures.

The face of the flange is either 1/16” or 1/4” depending on the pressure class. ANSI 300 and under have a 1/16” raised face and ANSI 400 and above have a 1/4” raised face.

Blind flange Weld neck flange Socket weld flange Slip on flange Thread flange

Raised Face Flange Lap Joint Flange

Hydrostatic Test

Hydrostatic Test

. Not required unless specifically requested by purchaser

. Code mandate that flange shall be able to withstand under pressure test of rating of finished part.

Non Destructive Testing

Non Destructive Testing

. Ultrasonic test

. Magnetic particle test o Liquid penetrant test

. Positive Material Identification

Destractive Testing

Destractive Testing

. Tensile test

. Hardness test

. Impact test / Charpy V-Notch Test

Metallurgical Test

Metallurgical Test

Chemical Analysis of -Raw material -Product·Special test

. Grain size (AS & SS)

. IGC- Intergranular Corrosion Test(SS) -Ferrite (SS)

. HIC- Hydrogen-induced Cracking

. SSC- Sulfide Stress Corrosion Cracking

Visual Inspection

Visual Inspection

. Check for any surface imperfection and overall product quality

. Check for unfinished machine surface

. Check for any serration damage on flange face

. Being a machined product no surface defect is acceptable.

Steel Pipe Flange Dimensional Tolerances

Steel Pipe Flange Dimensional Tolerances

This table displays Flange Dimensional Tolerances by inside, outside, and contact diameter, thickness, and drilling tolerances for bolt holes diameter and spacing. These standard flange dimensional tolerances are ideal when other specifications aren't used.

|

OUTSIDE DIAMETER |

When O.D. is 24" or less |

+0.125" , -0.0625" |

|

When O.D. over is 24" |

+0.125" , -0.125" |

|

|

INSIDE DIAMETER |

When I.D. is 10" or less |

+0.03125" , -0" |

|

When I.D. over is 10" |

+0.0625" , -0" |

|

|

CONTACT FACE DIAMETER |

Raised Face |

+0.0156" , -0.0156" |

|

DRILLING |

Bolt Hole Diameter |

+0.03125" , -0.03125" |

|

Bolt Circle Diameter |

+0.0625" , -0.0625" |

|

|

Bolt Hole Spacing |

+0.03125" , -0.03125" |

|

|

THICKNESS |

When nominal size is 18" or less |

+0.125" , -0 |

|

When nominal size is over 18" |

+0.1875" , -0 |

Chemical Composition (%) of ASTM A234/A234M

Chemical Composition (%) of ASTM A234/A234M

|

Grade |

Type |

C |

Si |

S |

P |

Mn |

Cr |

Ni |

Mo |

Other |

ób |

ós |

δ5 |

|

WPB |

0 |

0.1min |

0.058 |

0.05 |

0.29-1.06 |

0.4 |

0.4 |

0.15 |

V:0.06;Nb:0.02 |

415-585 |

240 |

22 |

197 |

|

WPC |

0.35 |

0.1min |

0.058 |

0.05 |

0.29-1.06 |

0.4 |

0.4 |

0.15 |

V:0.06;Nb:0.02 |

485-655 |

275 |

22 |

197 |

|

WP1 |

0.28 |

0.1-0.5 |

0.045 |

0.045 |

0.3-0.9 |

|

|

0.44-0.65 |

|

380-550 |

205 |

22 |

197 |

|

WP12 CL1 |

0.05-0.2 |

0.6 |

0.045 |

0.045 |

0.3-0.8 |

0.8-1.25 |

|

0.44-0.65 |

|

415-585 |

220 |

22 |

197 |

|

WP12 CL2 |

0.05-0.2 |

0.6 |

0.045 |

0.045 |

0.3-0.8 |

0.8-1.25 |

|

0.44-0.65 |

|

485-655 |

275 |

22 |

197 |

|

WP11 CL1 |

0.05-0.15 |

0.5-1 |

0.03 |

0.03 |

0.3-0.6 |

1-1.5 |

|

0.44-0.65 |

|

415-585 |

205 |

22 |

197 |

|

WP11 CL2 |

0.05-0.2 |

0.5-1 |

0.04 |

0.04 |

0.3-0.8 |

1-1.5 |

|

0.44-0.65 |

|

485-655 |

275 |

22 |

197 |

|

WP11 CL3 |

0.05-0.2 |

0.5-1 |

0.04 |

0.04 |

0.3-0.8 |

1-1.5 |

|

0.44-0.65 |

|

520-690 |

310 |

22 |

197 |

|

WP22 CL1 |

0.05-0.15 |

0.5 |

0.04 |

0.04 |

0.3-0.6 |

1.9-2.6 |

|

0.87-1.13 |

|

415-585 |

205 |

22 |

197 |

|

WP22 CL3 |

0.05-0.15 |

0.5 |

0.04 |

0.04 |

0.3-0.6 |

1.9-2.6 |

|

0.87-1.13 |

|

520-690 |

310 |

22 |

197 |

|

WP5 CL1 |

0.15 |

0.5 |

0.03 |

0.04 |

0.3-0.6 |

4-6 |

|

0.44-0.65 |

|

415-585 |

205 |

22 |

217 |

|

WP5 CL3 |

0.15 |

0.5 |

0.03 |

0.04 |

0.3-0.6 |

4-6 |

|

0.44-0.65 |

|

520-690 |

310 |

22 |

217 |

|

WP9 CL1 |

0.15 |

1 |

0.03 |

0.03 |

0.3-0.6 |

8-10 |

|

0.9-1.1 |

|

415-585 |

205 |

22 |

217 |

|

WP9 CL3 |

0.15 |

1 |

0.03 |

0.03 |

0.3-0.6 |

8-10 |

|

0.9-1.1 |

|

520-690 |

310 |

22 |

217 |

|

WPR |

0.2 |

|

0.05 |

0.045 |

0.4-1.06 |

|

1.6-2.24 |

|

|

435-605 |

315 |

22/28 |

217 |

|

WP91 |

0.08-0.12 |

0.2-0.5 |

0.01 |

0.02 |

0.3-0.6 |

8-9.5 |

0.4 |

0.85-1.05 |

See sdandard |

585-760 |

415 |

20 |

248 |

|

WP911 |

0.09-0.13 |

0.1-0.5 |

0.01 |

0.02 |

0.3-0.6 |

8.5-10.5 |

0.4 |

0.9-1.1 |

See sdandard |

620-840 |

440 |

20 |

248 |

Notes:

For each reduction of 0.01% below the specified C maximum, an increase of 0.06% Mn above the specified maximum will be permitted, up to a maximum of 1.35%.

The sum of Cu, Ni, Cr, and Mo shall not exceed 1.00%.

The sum of Cr and Mo shall not exceed 0.32%.

The maximum carbon equivalent (C.E.) shall be 0.50, based on heat analysis and the formula C.E.=C+Mn/6+(Cr+Mo+V)/5+(Ni+Cu)/15.

HuNan Province

+86-731-85648266

LiaoNing Province

+86-731-85648266

HeBei Province

+86-731-85648299

jiangsu Province

+86-731-85648299

TianJin City

Singapore