| Product: | LSAW pipe,Longitudinally Submerged Arc Welding Pipe |

| Application: | Used for oil/gas/water Transmission,Engineering/Offshore projects. |

| Size: | OD: 219mm-1625mm |

| WT: 6.35 mm – 60 mm | |

| LENGTH: 2 m – 18 m | |

| Pipe Standard: | API 5L PSL1/PSL2 Gr.A,Gr.B,X42,X46,X52,X56,X60,X65,X70 |

| ASTM A53 ASTM 572 ASTM A252 | |

| AN/NZS 1163 AN/NZS 1074 | |

| EN10219-1 EN10217-1 |

LSAW Steel Pipe Specification

LSAW Steel Pipe Specification

|

Product |

LSAW Pipe, Longitudinally Submerged Arc Welding Pipe |

|

Application |

Used for Oil / Gas / Water Transmission, Engineering / Offshore Projects |

|

Size |

OD: 219mm-1625mm |

|

|

WT:6.35 mm – 60 mm |

|

|

LENGTH: 5.8/6/11.8/12m |

|

Pipe Standard |

API 5L PSL1/PSL2 Gr.A,Gr.B,X42,X46,X52,X56,X60,X65,X70 |

|

|

ASTM A53/A252/A500/A672/A691/A139 |

|

|

EN10210/EN10219/EN10217/EN10208/EN10297 |

|

|

AN/NZS 1163 AN/NZS 1074

|

Product Display & Application

Product Display & Application

UOE SAWL Pipes

UOE SAWL Pipes

|

Outside Diameter |

Φ219mm- 1118mm (20"- 44") |

|

Wall Thickness |

6.0-25.4mm 1/4"-1" |

|

Quality Standards |

API、DNV、ISO、DEP、EN、ASTM、DIN、BS、JIS、GB、CSA |

|

Length |

9-12.3m (30'- 40') |

|

Grades |

API 5L A-X90,GB/T9711 L190-L625 |

JCOE SAWL Pipes

JCOE SAWL Pipes

|

Outside Diameter |

Φ406mm- 1626mm (16" - 64" ) |

|

Wall Thickness |

6.0- 75mm (1/4" - 3" ) |

|

Quality Standards |

API、DNV、ISO、DEP、EN、ASTM、DIN、BS、JIS、GB、CSA |

|

Length |

3-12.5m ( 10'- 41' ) |

|

Grades |

API 5L A-X100, GB/T9711 L190-L690 |

Features Of Longitudinally Submerged Arc Welding Steel Pipe

Features Of Longitudinally Submerged Arc Welding Steel Pipe

- Large diameter

- Thick walls

- High pressure resistance

- Low temperature resistance

UOE LSAW Pipe Forming Process:

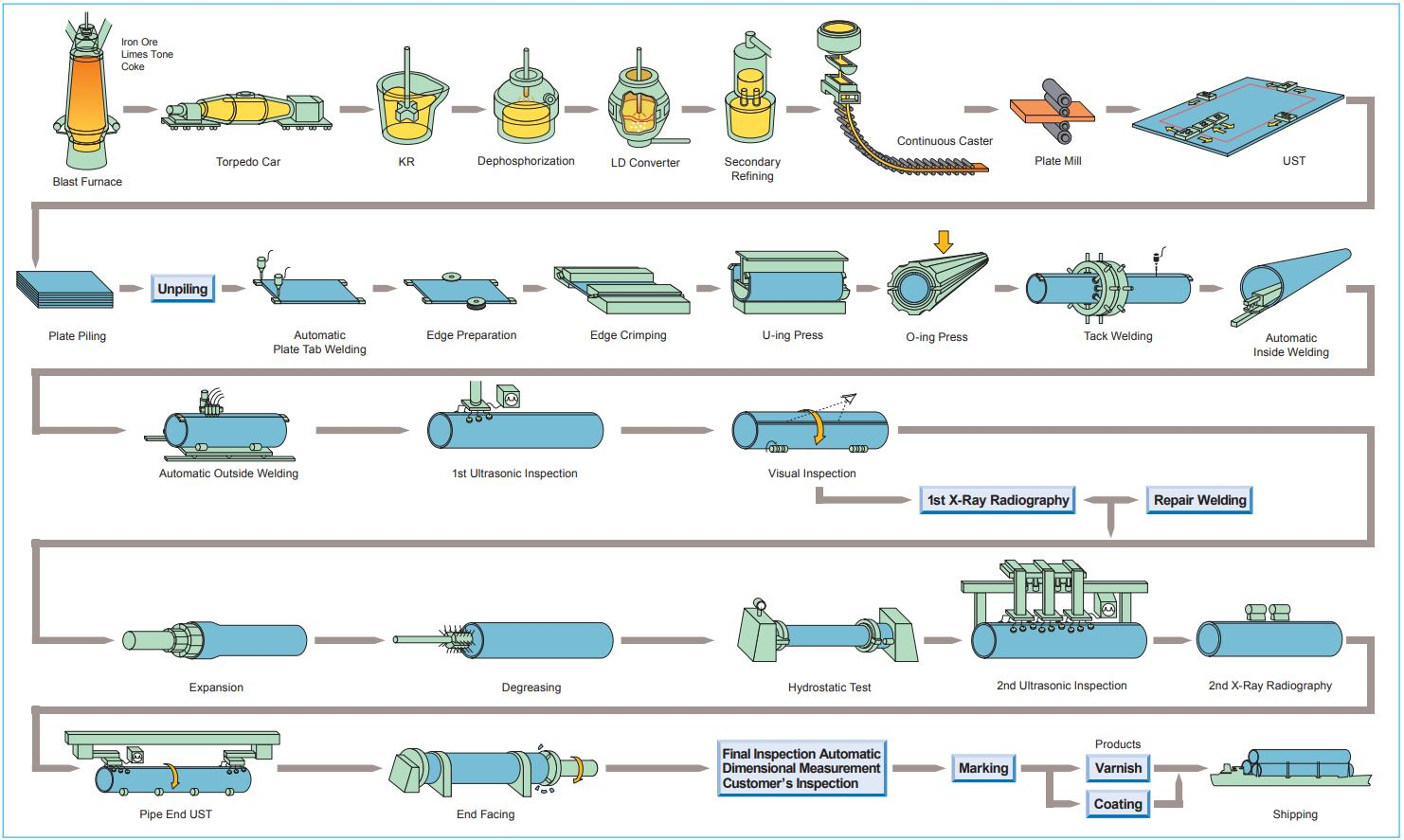

The three main forming processes of UOE LSAW steel pipe forming process include: steel plate pre-bending, U forming and O forming. Each process adopts a dedicated forming press to complete the three processes of pre-bending the edge of the steel plate, U forming and O forming in sequence to deform the steel plate into a circular tube.

JCOE LSAW Pipe Forming Process:

Forming: After several steps of stamping on the JCO forming machine, first half of the steel plate is pressed into a "J" shape, then the other half of the steel plate is pressed into a "J" to form a "C" shape, and finally pressurized from the middle to form An open "O"-shaped tube blank is formed.

- Chemical Component Analysis

- Mechanical Properties

- Elongation, Yield Strength, Ultimate Tensile Strength

- Technical Properties

- DWT Test, Impact Test, Blow Test, Flattening Test

- X-Ray Test

LSAW Pipe Tolerance of Outside Diameter and Wall Thickness

LSAW Pipe Tolerance of Outside Diameter and Wall Thickness

|

Types |

Standard |

|||||

|

SY/T5040-2000 |

SY/T5037-2000 |

SY/T9711.1-1977 |

ASTM A252 |

AWWA C200-97 |

API 5L PSL1 |

|

|

Tube end OD deviation |

±0.5%D |

±0.5%D |

-0.79mm~+2.38mm |

<±0.1%T |

<±0.1%T |

±1.6mm |

|

Wall thickness |

±10.0%T |

D<508mm, ±12.5%T |

-8%T~+19.5%T |

<-12.5%T |

-8%T~+19.5%T |

5.0mm |

|

D>508mm, ±10.0%T |

T≥15.0mm, ±1.5mm |

|||||

Chemical Composition and Mechanical Properties of LSAW Steel Pipe

Chemical Composition and Mechanical Properties of LSAW Steel Pipe

|

Sandard |

Grade |

Chemical Composition(max)% |

Mechanical Properties(min) |

|||||

|

C |

Mn |

Si |

S |

P |

Yield Strength (Mpa) |

Tensile Strength (Mpa) |

||

|

GB/T700-2006 |

A |

0.22 |

1.4 |

0.35 |

0.050 |

0.045 |

235 |

370 |

|

B |

0.2 |

1.4 |

0.35 |

0.045 |

0.045 |

235 |

370 |

|

|

C |

0.17 |

1.4 |

0.35 |

0.040 |

0.040 |

235 |

370 |

|

|

D |

0.17 |

1.4 |

0.35 |

0.035 |

0.035 |

235 |

370 |

|

|

GB/T1591-2009 |

A |

0.2 |

1.7 |

0.5 |

0.035 |

0.035 |

345 |

470 |

|

B |

0.2 |

1.7 |

0.5 |

0.030 |

0.030 |

345 |

470 |

|

|

C |

0.2 |

1.7 |

0.5 |

0.030 |

0.030 |

345 |

470 |

|

|

BS EN10025 |

S235JR |

0.17 |

1.4 |

- |

0.035 |

0.035 |

235 |

360 |

|

S275JR |

0.21 |

1.5 |

- |

0.035 |

0.035 |

275 |

410 |

|

|

S355JR |

0.24 |

1.6 |

- |

0.035 |

0.035 |

355 |

470 |

|

|

DIN 17100 |

ST37-2 |

0.2 |

- |

- |

0.050 |

0.050 |

225 |

340 |

|

ST44-2 |

0.21 |

- |

- |

0.050 |

0.050 |

265 |

410 |

|

|

ST52-3 |

0.2 |

1.6 |

0.55 |

0.040 |

0.040 |

345 |

490 |

|

|

JIS G3101 |

SS400 |

- |

- |

- |

0.050 |

0.050 |

235 |

400 |

|

SS490 |

- |

- |

- |

0.050 |

0.050 |

275 |

490 |

|

|

API 5L PSL1 |

A |

0.22 |

0.9 |

- |

0.03 |

0.03 |

210 |

335 |

|

B |

0.26 |

1.2 |

- |

0.03 |

0.03 |

245 |

415 |

|

|

X42 |

0.26 |

1.3 |

- |

0.03 |

0.03 |

290 |

415 |

|

|

X46 |

0.26 |

1.4 |

- |

0.03 |

0.03 |

320 |

435 |

|

|

X52 |

0.26 |

1.4 |

- |

0.03 |

0.03 |

360 |

460 |

|

|

X56 |

0.26 |

1.1 |

- |

0.03 |

0.03 |

390 |

490 |

|

|

X60 |

0.26 |

1.4 |

- |

0.03 |

0.03 |

415 |

520 |

|

|

X65 |

0.26 |

1.45 |

- |

0.03 |

0.03 |

450 |

535 |

|

|

X70 |

0.26 |

1.65 |

- |

0.03 |

0.03 |

585 |

570 |

|

HuNan Province

+86-731-85648266

LiaoNing Province

+86-731-85648266

HeBei Province

+86-731-85648299

jiangsu Province

+86-731-85648299

TianJin City

Singapore