| Application: | Widely used in furniture,interior decoration, structure |

| Size: | OD: 10*10-1000*1000mm |

| Pipe Standard: | GB/T 3094-2000, GB/T 6728-2002, DIN EN 10210, DIN EN 10219, GB/T 178-2005,ASTM A53, ASTM A500,BS EN 10219,JIS G 3466, ASTM A513, ASTM A36 |

| S235JR,S355JR,Q235,St37,St37-2,St52,SS400, STK500,Q235B, Q345 | |

| Furface: | Black bared ,can be galvanized,oiled,painted,powdered. |

| Packing: | Waterproof plastic bag,bundle with strip |

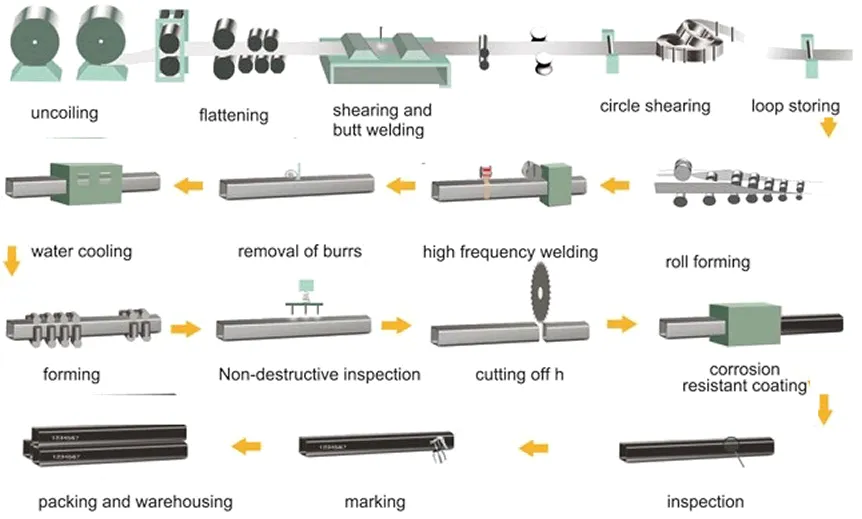

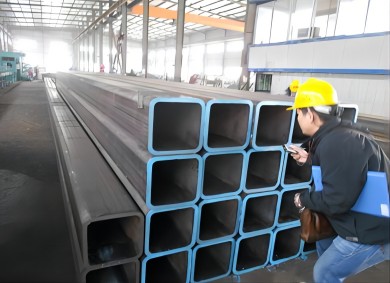

Square Steel Pipe Introduction

Square Steel Pipe Introduction

|

Application: |

Widely used in furniture,interior decoration, structure |

|

Size: |

OD: 10*10-1000*1000mm |

|

Pipe Standard: |

DIN EN 10210, DIN EN 10219, GB/T 178-2005,ASTM A53, ASTM A500,BS EN 10219,JIS G 3466, ASTM A513, ASTM A36 |

|

S235JR,S355JR,Q235,St37,St37-2,St52,SS400, STK500,Q235B, Q345 |

|

|

Furface: |

Black bared ,can be galvanized,oiled,painted,powdered. |

|

Packing: |

Waterproof plastic bag,bundle with strip |

|

Application: |

Widely used in furniture,interior decoration, structure |

|

Size: |

OD: 10*10-1000*1000mm |

Standard of Square Steel Pipe

Standard of Square Steel Pipe

ASTM A500 Grade B,

ASTM A513 (1020-1026)

ASTM A36 (A36)

EN 10210: S235, S355, S235JRH, S355J2H, S355NH

EN 10219: S235, S355, S235JRH, S275J0H, S275J2H, S355J0H, S355J2H

|

Size by Inch (diameter) |

Thickness |

Sizes by MM (diameter) |

Thickness |

|

inch |

inch |

mm |

mm |

|

1/2" x 1/2" |

0.065" |

16mm×16mm |

0.4mm~1.5mm |

|

3/4" x 3/4" |

0.049" |

18mm×18mm |

0.4mm~1.5mm |

|

0.065" |

20mm×20mm |

0.4mm~3mm |

|

|

0.083" |

22mm×22mm |

0.4mm~3mm |

|

|

0.120" |

25mm×25mm |

0.6mm~3mm |

|

|

1" x 1" |

0.049" |

30mm×30mm |

0.6mm~4mm |

|

0.058" |

32mm×32mm |

0.6mm~4mm |

|

|

0.065" |

34mm×34mm |

1mm~2mm |

|

|

0.072" |

35mm×35mm |

1mm~4mm |

|

|

0.083" |

38mm×38mm |

1mm~4mm |

|

|

0.095" |

40mm×40mm |

1mm~4.5mm |

|

|

0.109" |

44mm×44mm |

1mm~4.5mm |

|

|

0.120" |

45mm×45mm |

1mm~5mm |

|

|

1 1/8" x 1 1/8" |

0.035" |

50mm×50mm |

1mm~5mm |

|

0.049" |

52mm×52mm |

1mm~5mm |

|

|

0.065" |

60mm×60mm |

1mm~5mm |

|

|

0.109" |

70mm×70mm |

2mm~6mm |

|

|

0.120" |

75mm×75mm |

2mm~6mm |

|

|

1 1/4" x 1 1/4" |

0.049" |

76mm×76mm |

2mm~6mm |

|

0.065" |

80mm×80mm |

2mm~8mm |

|

|

0.072" |

85mm×85mm |

2mm~8mm |

|

|

0.083" |

90mm×90mm |

2mm~8mm |

|

|

0.109" |

95mm×95mm |

2mm~8mm |

|

|

0.120" |

100mm×100mm |

2mm~8mm |

|

|

0.135" |

120mm×120mm |

4mm~8mm |

|

|

0.156" |

125mm×125mm |

4mm~8mm |

|

|

0.188" |

130mm×130mm |

4mm~8mm |

|

|

1 1/2" x 1 1/2" |

0.049" |

140mm×140mm |

6mm~10mm |

|

0.065" |

150mm×150mm |

6mm~10mm |

|

|

0.072" |

160mm×160mm |

6mm~10mm |

|

|

0.083" |

180mm×180mm |

6mm~12mm |

|

|

0.109" |

200mm×200mm |

6mm~30mm |

|

|

0.120" |

220mm×220mm |

6mm~30mm |

|

|

0.140" |

250mm×250mm |

6mm~30mm |

|

|

0.188" |

270mm×270mm |

6mm~30mm |

|

|

0.250" |

280mm×280mm |

6mm~30mm |

|

|

1 3/4" x 1 3/4" |

0.065" |

300mm×300mm |

8mm~30mm |

|

0.083" |

320mm×320mm |

8mm~30mm |

|

|

0.095" |

350mm×350mm |

8mm~30mm |

|

|

0.109" |

380mm×380mm |

8mm~30mm |

|

|

0.120" |

400mm×400mm |

8mm~30mm |

|

|

0.188" |

420mm×420mm |

10mm~30mm |

|

|

2" x 2" |

0.049" |

450mm×450mm |

10mm~30mm |

|

0.065" |

480mm×480mm |

10mm~30mm |

|

|

0.083" |

500mm×500mm |

10mm~30mm |

|

|

0.109" |

550mm×550mm |

10mm~40mm |

|

|

0.120" |

600mm×600mm |

10mm~40mm |

|

|

0.145" |

700mm×700mm |

10mm~40mm |

|

|

0.165" |

800mm×800mm |

10mm~50mm |

|

|

0.188" |

900mm×900mm |

10mm~50mm |

|

|

0.250" |

1000mm×1000mm |

10mm~50mm |

|

|

0.312" |

|

|

|

|

2 1/4" x 2 1/4" |

0.188" |

|

|

|

0.250" |

|

|

|

|

2 1/2" x 2 1/2" |

0.083" |

|

|

|

0.109" |

|

|

|

|

0.120" |

|

|

|

|

0.188" |

|

|

|

|

0.250" |

|

|

|

|

0.312" |

|

|

Advantages of Square Steel Pipe

Advantages of Square Steel Pipe

Used for a variety of applications, some benefits of square tubing include:

Cost-effective

Strength

Uniformity

Metallurgical Tests

Metallurgical Tests

Metallurgical Tests confirm that the chemical requirements of the pipe are as per the material standard.

· Metallurgical Tests are normally known as Micro and Macro pipe inspection & testing.

· Micro Analysis or Chemical Analysis of

1. Raw material

2. Product

3. Weld ensures that all the alloying elements are within the range as specified in the material standard.

· Macro Analysis for Weld will check the proper fusion of weld material with pipe material.

Some special pipe inspection tests are also carried out on the material when it is going to be used in aggressive environments. These tests will ensure that pipe material is able to withstand in such aggressive environments also. Some of the tests are

· Grain size (AS & SS)

· IGC- Intergranular Corrosion Test(SS)

· Ferrite (SS)

· HIC- Hydrogen-induced Cracking

· SSC- Sulfide Stress Corrosion Cracking

These tests are performed when it is asked by the purchaser in his specification.

Destructive Test

Destructive Test

The mechanical / Destructive test of pipe inspection confirms the mechanical requirements of pipe are as per the material standard.

In Destructive Testing- a sample from the pipe is cut to perform tests

· The tensile test is done to check the yield and ultimate tensile of the pipe. If required by the purchaser or by standard high or low-temperature tensile tests are also performed.

· Bend test / Guided bend test is used to check the integrity of weld joint

· The flattening test examines the ability of plastic deformation in a pipe

· Impact test / Charpy V-Notch Test, check the ability of a material to withstand low-temperature conditions

· A creep test is done to check the long-term effect of temperature under constant load.

|

Square Steel Pipe Dimensional Tolerances |

|||

|

Outside Diameter: |

Twist: |

Maximum twist per 3 feet of length |

|

|

Largest outside dimension |

Outside tolerance including convexity and concavity |

Longest outside dimension |

|

|

up to 2 1/2" |

±.020" |

2" to 2 1/2"inclusive |

.062" |

|

over 21/2" to 31/2" inclusive |

±.025" |

over 21/2" to 4" inclusive |

.075" |

|

over 31/2" to 51/2" inclusive |

±.030" |

over 4" to 6" inclusive |

.087" |

|

over 51/2" |

±1% |

over 6" to 8" inclusive |

100" |

|

Tolerances include allowance for convexity or concavity. For |

over 8" |

112" |

|

|

Straightness: |

|||

|

.125" x (total length)÷5 |

|||

|

Wall Thickness: |

Squareness of Sides: |

||

|

Maximum allowable variation |

±10% |

Adjacent sides may deviate from 90°by a tolerance of plus or minus 2 degrees maximum. |

|

|

(wall thickness is to be measured at the center of the flat, exclusive |

|||

|

Worner Radii: |

Flash: |

||

|

The radius of any outside corner shal not exceed three times |

Structural tubing usually is supplied flash-in. The height of the |

||

|

Grade |

Element |

C |

Mn |

P |

S |

|

ASTM A500 Gr.b |

% |

0.05%-0.23% |

0.3%-0.6% |

0.04% |

0.04% |

|

Acc.to EN10027/1 |

Acc.to EN10027/2 |

C% max (Norminal W.T.(mm) |

Si% max |

Mn% max |

P% max |

S% max |

N% max |

|

|

and IC 10 |

|

≤ 40 |

|

|||||

|

S235JRH |

1.0039 |

0.17 |

0.20 |

- |

1.40 |

0.045 |

0.045 |

0.009 |

|

S275JOH |

1.0149 |

0.20 |

0.22 |

- |

1.50 |

0.040 |

0.040 |

0.009 |

|

S275J2H |

1.0138 |

0.20 |

0.22 |

- |

1.50 |

0.035 |

0.035 |

- |

|

S355JOH |

1.0547 |

0.22 |

0.22 |

0.55 |

1.60 |

0.040 |

0.040 |

0.009 |

|

S355J2H |

1.0576 |

0.22 |

0.22 |

0.55 |

1.60 |

0.035 |

0.035 |

- |

HuNan Province

+86-731-85648266

LiaoNing Province

+86-731-85648266

HeBei Province

+86-731-85648299

jiangsu Province

+86-731-85648299

TianJin City

Singapore