With the development of the world's petroleum industry, the conditions for oil well exploitation are becoming more and more harsh, and the corrosion of CO2 on the oil casing is also very serious, resulting in an increase in the corrosion rate of the steel pipe and severe localized corrosion, and even pitting and perforation of the oil casing invalidated. CO2 corrosion has become a worldwide problem and one of the important factors threatening oilfield production safety. At present, high-Cr alloys have good CO₂ corrosion resistance, among which 13Cr and super 13Cr have become the recommended materials for oil casing products due to their excellent CO₂ corrosion resistance.

L80-13Cr tubing is a high-Cr product with the largest demand in the petroleum industry, and its ends are generally processed into special threads with good sealing performance and high connection strength. Compared with API thickened tubing, thickened tubing with special threaded joints requires a thicker and longer thickened end, which brings great challenges to end forming and mechanical property control. Only a few companies at home and abroad can produce L80 -13Cr special thread thickened tubing.

Characteristics of L80-13Cr steel pipe

● Chemical composition and processing characteristics

L80-13Cr steel used in the test and GB/T 1220—2007 "Stainless steel

The chemical composition of the martensitic stainless steel 20Cr13 in "Steel Bars" is similar, which meets the requirements of API Spec 5CT-2011 "Casing and Tubing Specifications". The chemical composition of L80-13Cr steel is shown in Table 1.

Chemical composition (mass fraction) of table 1L80-13Cr steel

|

require |

C |

|

Si |

Mn |

P S Cu |

Ni |

Cr Mo % |

|

measured value |

0.18 |

|

0.62 |

0.59 |

0.014 0.005 0.092 |

0.18 |

13.18 0.019 |

|

API Spec 5CT- -2011 required value |

0.15~0. |

22 |

≤1.00 |

0.25~1. |

00 ≤0.020 ≤0.010 ≤0.25 |

≤0.50 |

12.0~14.0 |

|

GB / T 1220- -2007 requirement value (20 Cr 13) |

0.16~0. |

25 |

≤1.00 |

≤1.00 |

≤0.040 ≤0.030 |

12.0~14.0 ≤0.60 |

|

80-13Cr is a high-alloy steel with an alloy content close to 15%. The deformation resistance of this type of steel at high temperature is about 1.5 times that of carbon steel. In order to improve the processing and forming properties of metals, the resistance of materials in the process of plastic deformation is generally reduced by increasing the thermal processing temperature.

● Mechanical properties

In the test, the L80-13Cr sample was austenitized in a muffle furnace at 1000 °C for 30 min. After the sample came out of the furnace, it was air-cooled to room temperature, and then the samples were tempered in a muffle furnace at 650-750 °C for 60 min. min. The tensile and impact properties of L80-13Cr special threaded thickening tubing body are shown in Table 2.

Table 2 Tensile and impact properties of L80-13Cr special thread thickened tubing body

|

Test sample tempering temperature / ℃ |

yield strength /MPa |

tensile property tensile strength /MPa |

yield ratio |

Rockwell hardness HRC |

|

720 |

635 |

805 |

0.79 |

22.9 |

|

730 |

569 |

759 |

0.75 |

20.9 |

|

API Spec 5CT—2011require |

552~655 |

≥655 |

|

≤23 |

● Production process

The production process of L80-13Cr special thread thickening oil pipe is: steel pipe with qualified size → pipe end thickening → heat treatment → heat straightening → performance inspection → ultrasonic flaw detection → steel pipe size inspection and appearance inspection → hydraulic test → pipe end turning To the size of the drawing→flaw detection of the thickening end and blind area of the pipe end→sandblasting the inner and outer surfaces of the steel pipe→labeling→packing and warehousing.

● Ththe pipe end

In order to ensure that the size of the thickened end and the metallographic tissue meet the requirements, the heating temperature is strictly controlled below 1280℃; in order to weaken the deformation resistance of 13 Cr material due to low temperature heating, multiple small deformation thickening process is used to make the thickened end. Through the reasonable calculation and allocation of the thickening deformation of each channel, and to design the pipe end thickened mold, to ensure that the size of the pipe end meets the design requirements.

● and the heat treatment

L80-13 Cr special thread thickened oil pipe is heat treated by step heat treatment furnace. The austenite temperature is 980℃, cooled cooled below 50℃ in air. The hardness of the pipe body and the thickened ends of the L80-13 Cr thread is shown in Table 3. According to the API Spec 5CT- -2011 specification, the hardness HRC formula corresponding to the martensite content of 95% after the quenching of the steel material is:

HRC=59xw(C)+29 (1)

The Rockwell hardness value of the HRC —— quenched material, in Eq.

The step-type heat treatment furnace is used to recharge the L80-13 Cr special thread thickened oil pipe after air cooling. Select 723℃ heating, the control steel pipe in the furnace time is 200min, air cooling to room temperature after the oven.

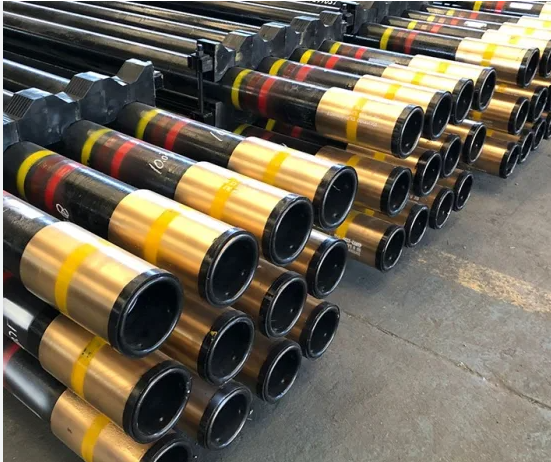

● Physical products Through the inner boring, outer car and flat head treatment of the L80-13 Cr, the outer diameter, inner diameter and length of the thickened end of the L80-13 Cr are processed to the drawing Paper specified size. Qualified L80-13 Cr special thread thickened oil pipe after spraying mark, use support packaging to prevent impact. The L80-13 Cr packed to be shipped is shown in Figure 5.

Through a reasonable thickening process design, the δ ferrite in the thickened oil tubing with L80-13Cr special thread is avoided; the product pipe end size meets the customer's requirements.

Through the design of heat treatment process, the problem that the mechanical properties of 13Cr products are difficult to control has been solved, and the performance of L80-13Cr special thread thickened tubing body and thickened end has been achieved.