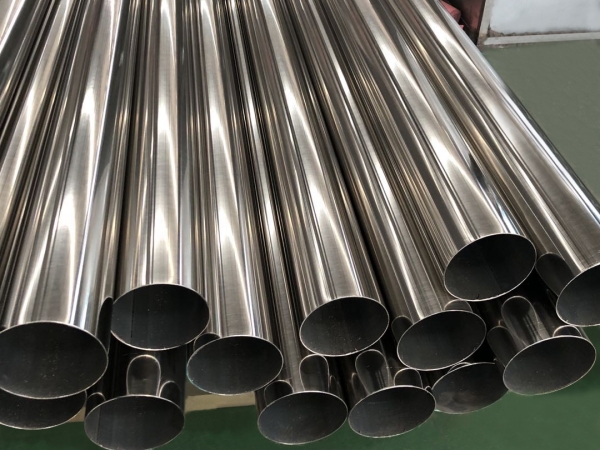

201 stainless steel welded pipe is normally produced from 201 stainless steel stripes by welding, including round,square and rectangular shape. The outer surface of 201 stainless steel welded pipe is normally mirror polished. And if customer needed, we - United Steel Industry can polish both inside and outside of the pipes. This article will talk about 201 stainless steel welded pipe welding method.

Welding Method of 201 Stainless Steel Welded Pipe:

- Gas Shielded Welding:

Mainly refers to TIG welding, melting electrode TIG welding and carbon dioxide (CO2) gas shielded welding. TIG welding has a stable arc, uses small current to weld thin parts, and can weld single-sided and double-sided form welding. Therefore, it is widely used in boiler and pressure vessel manufacturing and installation projects. Commonly used for circumferential seam welding of 230 stainless steel welded pipes, cylindrical vessels and pipes in small-diameter boilers. The special rotating mechanism can also be used to automatically weld the welds of boiler and heat exchanger tube plate structures. Melting arc welding is often used to weld thin-walled 201 stainless steel welded pipes and alloy steel containers. Electrode pulse argon arc welding is mainly used for butt welds of small diameter thick wall pipes and narrow gap welds on thick wall components.

- Electron Beam Welding:

Has been applied to pressure vessels. This welding method has narrow welding and heat-affected zones, simple connectors, and high production efficiency. It has been practically used in nuclear reactor vessels, boiler drums, deep potential vessels and spherical vessels.

Applications of 201 Stainless Steel Welded Pipe:

- Process exhaust system

- Solvent exhaust system

- Organic exhaust system

- Exhaust gas exhaust system

- Outdoor part of ordinary exhaust system

- Hot and humid exhaust system

- Smoke and dust removal system