1. Standard specification

Both standards are standard specifications for ferritic-ausic stainless steel tubing used in corrosive environments. ASTM A790 specifies the elements and requirements for the manufacture of seamless and welded pipes, while ASTM A928 covers only electric fusion welded pipes. ASTM A790 requires that duplex and super duplex steel pipes be welded without the addition of any filler metal. ASTM A928 requires that the weld be welded with the addition of filler metal.

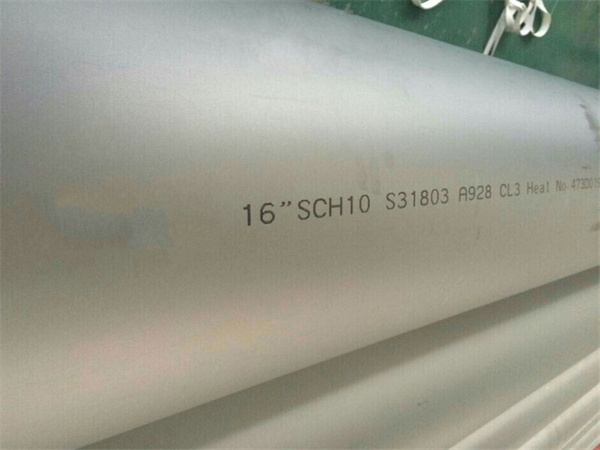

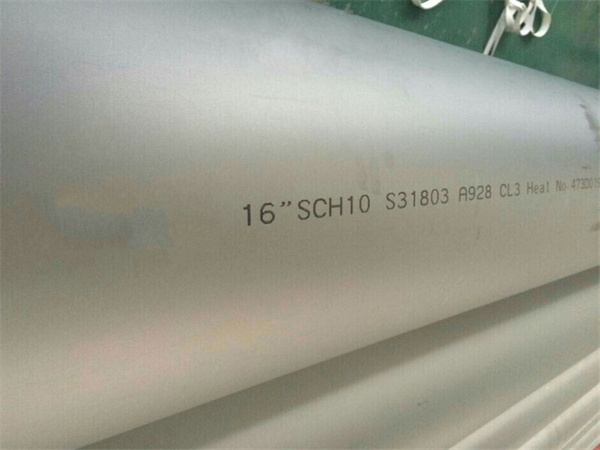

ASTM A928 duplex steel pipes ASTM A790 duplex steel pipes

2. Manufacturing process

The manufacturing processes listed in the ASTM A790 and ASTM A928 duplex steel pipes standards also provide manufacturers with some freedom of choice. For example, under the specific conditions that the raw material (coil or plate) has been solution annealed, both standards allow the finished pipe not to anneal, and the steel pipe in this case will be marked with HT-0. However, the ASTM A790 standard has restrictions on this situation: when using UNS S31803, S32205, S32750, S32760 and S32520 materials to produce steel pipes, corrosion tests must be supplemented. The buyer and the manufacturer must agree on specific differences between the two standards.

ASTM A928 divides products into five different levels:

Level 1: All weld passes of the steel pipe shall be welded on both sides by adding filler metal, and X-ray inspection shall be performed on all

Level 2: All weld passes of steel pipes shall be welded on both sides by adding filler metal, but X-ray inspection is not required

Level 3: All weld passes of the steel pipe shall be welded on one side by adding filler metal, and X-ray inspection shall be performed on all

Level 4: All weld passes of the steel pipe shall be welded on one side by adding filler metal, but the welding passes on the inner surface of the steel pipe may not be filled with filler metal, and all X-ray inspections shall be performed

Grade 5: All weld passes of the steel pipe shall be double-sided welded by adding filler metal, and X-ray sampling inspection shall be carried out (every 15m weld shall be inspected not less than 300mm)

3. Size

ASTM A790 covers steel pipe diameters from 1/8″ (10.29mm) to 30″ (762.0mm), with wall thicknesses ranging from 1.24mm to 12.7mm. Based on ANSI B36.10 for steel pipes, larger diameter steel pipes are available in accordance with A790. For steel pipes with a diameter exceeding 48″ (1219.2mm), since they are not covered in the relevant standard ASTM A999, such steel pipes must meet the diameter tolerance and out-of-roundness tolerance respectively. The wall thickness tolerance ≤ 12.5% required in ASTM A999 is also applicable For steel pipes with a wall thickness exceeding 12.7mm. ASTM A928 refers to the ASTM A999 standard covering diameters from 1/8″ (10.29mm) to 48″ (1219.2mm). ANSI B36.10 for steel pipes is basis, larger diameter steel pipes are available in accordance with A928. For pipes with diameters over 48″ (1219.2mm), such steel pipes must meet diameter tolerances and out-of-roundness, respectively, as they are not covered in the related standard ASTM A999 tolerance. The wall thickness of steel pipes in ASTM A999 ranges from 1.7mm to 59.5mm.

In order to make the product meet the steel pipe tolerances stipulated by the two standards, the pressure of the production plant is very high (see Table 1).

4. (batch) destruction test

Within BUTTING, for the destructive tests specified in the ASTM A790 and ASTM A928 standards, from sample preparation to recording documents, it must be carried out in accordance with DIN ENISO 17025:2000 certified by the material testing laboratory. Required tests include tensile, hoop tensile, and bending tests and hardness measurements. Table 2 is a comparison of the destructive test requirements in ASTM A928 and ASTM A790.

5. Non-destructive testing

Table 3 shows the different non-destructive testing requirements of the two standards.

6. The importance of practice

This article compares the standards based on the current general standards, and only reflects some of the most important features in the steel pipe production, and the details are inevitable. anyway,

This article compares the standards based on the current general standards, and only reflects some of the most important features in the steel pipe production, and the details are inevitable. In any case, the differences between the standards must be agreed upon between the acquirer and the manufacturer. In this regard, BUTTING could have followed ASTM A790 to produce thick-walled steel pipes by welding without filler metal. That is to say, a steel pipe with a wall thickness of 9.52mm or 12.7mm could have been welded without filler metal. But this is contrary to our actual experience. As a manufacturer of high-quality steel pipes, United Steel Industry CO.,LTD does not recommend purchasing steel pipes in this way, but recommends that the wall thickness > 4mm in ASTMA928 be used. purchase. After welding with the method of adding filler metal, the weldment can meet more corrosion resistance requirements specified in ASTMA928, so it is the first choice for production. It should also be pointed out that BUTTING only welds steel pipes with an outer diameter <114.3mm on one side, so if there is no separate agreement, this type of steel pipe can only be supplied according to grade 3 in ASTM A928.