DIN 30670 outlines the criteria governing the application of factory-applied coatings featuring a three-layer extruded polyethylene or polyethylene-based formulation. These coatings are designed to safeguard steel pipes and components from corrosion. The DIN 30670 coating is applicable to longitudinal, DSAW (Double Submerged Arc Welded) pipes, seamless steel pipes, and fittings employed in pipeline construction to transport liquids or gases. This coating system proves effective in safeguarding steel pipes, whether buried underground or submerged in water, within a temperature range extending from -40°C to +80°C.

Specifications of DIN 30670 PE Coated Pipe:

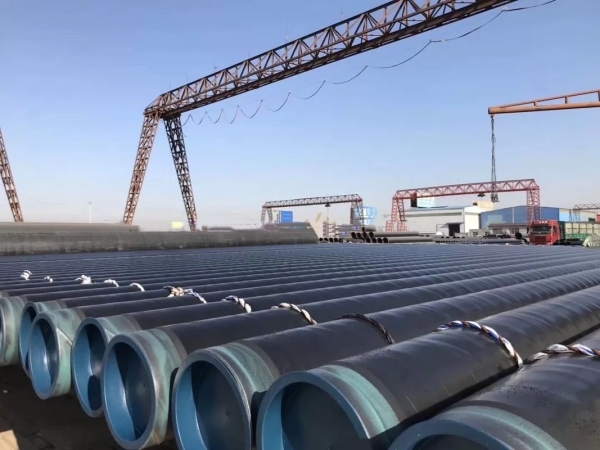

DIN 30670 seamless steel pipe with Polyethylene coatings

DIN 30670 DSAW steel pipe with Polyethylene coatings

DIN 30670 welded steel pipe with Polyethylene coatings

Size: 10.3-1020mm * 2mm-40mm(1/4”- 40”)

WT: 1.24mm - 60mm (SCH10-SCH160)

Length: 5.8M; 6M; 11.8 M, 12M or as customer's requirement

|

Nominal size of pipe |

Minimum thickness of normal coating(n), in mm |

Minimum thickness of Reinforced coating(v), in mm |

|

≤DN100 |

1.8 |

2.5 |

|

DN 100 - DN250 |

2.0 |

2.7 |

|

DN 250 - DN500 |

2.2 |

2.9 |

|

DN500 - DN800 |

2.5 |

3.2 |

|

≥DN800 |

3.0 |

3.7 |

In summary, DIN 30670 PE coated pipes are steel pipes that have undergone a protective coating process using three-layer extruded polyethylene, meeting the standards set by DIN 30670 to ensure corrosion resistance and durability in various industrial applications.