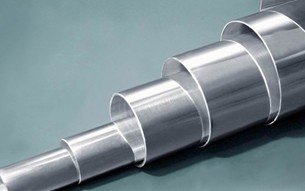

201 stainless steel welded pipe

201 stainless steel welded pipe, has the characteristics of acid resistance, alkali resistance, high density, polishing without bubbles, and no pinholes. It is a high-quality material for the production of various watch cases and watch strap bottom covers. It is mainly used to make decorative pipes, industrial pipes, and some shallow stretched products.201 stainless steel welded pipe is the international stainless steel marking method

201 stainless steel welded pipe --S20100 (AISI.ASTM)

The American Iron and Steel Institute uses three digits to mark various standard grades of malleable stainless steel. in:④ Stainless steel, precipitation hardening stainless steel, and high alloys with an iron content below 50% are usually under proprietary or trade names.

202 stainless steel welded pipe

202 stainless steel pipe chemical composition:

C ≤0.15%

Mn~7.5-10 , P≤0.06

S≤0.03

Ni ~ 4.0-6.0

Cr~17.0-19.0

Physical properties of 202 stainless steel pipe

The physical properties of 202 and the corresponding 300 series steel in the solution treatment state, the physical properties of 200 series and 300 series are not much different, almost equivalent. However, the change of magnetic permeability after cold working is different. Due to the different degrees of martensite induced during cold working, the increase of magnetic permeability is smaller than that of 200 series and 300 series.

Mechanical properties of 202 stainless steel pipes

201 and 202 are different from other 200 series materials. Like 301 and 302, they are all metastable austenitic stainless steels, which have greater work hardening. These steels have work hardening curves. 201 has similar hardening characteristics to 301 and 202 to 302. 201, 301 have greater work hardening. The amount of martensite formed is different for each brand, 202 and 304 produce very little martensite, and work hardening mainly depends on deformity. For steel types below 204 and 204L, work hardening is almost all based on distortion. The mechanical properties and magnetic permeability of CrMnN series materials are shown in Table 5. The hardness of these steels in the solution treatment state is about HV250, and the strength after cold rolling is higher, and the Hv can reach 500, but the magnetic permeability is still lower than 1.005 in this state.

309S stainless steel welded pipe

The use of stainless steel welded pipe

GB/T12770-2002 (Stainless steel welded steel pipes for mechanical structures). Mainly used in machinery, automobiles, bicycles, furniture, hotel and restaurant decoration and other mechanical parts and structural parts. Its representative materials are 0Cr13, 1Cr17, 00Cr19Ni11, 1Cr18Ni9, 0Cr18Ni11Nb, etc.

GB/T12771-2008 (stainless steel welded steel pipes for fluid transportation). It is mainly used for conveying low-pressure corrosive media. Representative materials are 06Cr19Ni10, 022Cr19Ni10, 06Cr19Ni110Ti, 00Cr17, 0Cr18Ni11Nb, 06Cr17Ni12Mo2, etc.

specification structure

|

wire gage(AWG ) |

linear structure Number of roots / wire diameter(mm ) |

thickness (mm ) |

Average outer diameter (mm ) |

The DC resistance at 20℃ (Ω/km ) |

Packaging length (m ) |

|

10 |

37 × 0.43 |

0.33 |

3.67 |

3.546 |

305 |

|

12 |

19 × 0.49 |

0.33 |

3.11 |

5.64 |

305 |

|

14 |

19 × 0.37 |

0.33 |

2.51 |

8.96 |

305 |

|

16 |

19 × 0.30 |

0.20 |

1.90 |

14.6 |

305 |

|

17 |

19 × 0.26 |

0.20 |

1.70 |

18.3 |

305 |

|

18 |

19 × 0.23 |

0.20 |

1.55 |

23.2 |

305 |

|

20 |

19 × 0.20 |

0.14 |

1.23 |

36.7 |

305 |

|

1 × 0.80 |

0.14 |

1.08 |

35.2 |

305 |

|

|

22 |

19 × 0.16 |

0.14 |

1.08 |

59.4 |

610 |

|

1 × 0.65 |

0.14 |

0.93 |

56.4 |

610 |

|

|

24 |

7 × 0.20 |

0.14 |

0.88 |

94.2 |

610 |

|

1 × 0.50 |

0.14 |

0.78 |

89.3 |

610 |

|

|

26 |

7 × 0.16 |

0.14 |

0.76 |

150 |

610 |

|

|

|

|

|

|

|

Stainless steel welded pipe weight calculation formula

outer diameter - wall thickness) x wall thickness x0.02491x length = weight (kg)

904L stainless steel welded pipe

Welding characteristics of stainless steel welded pipe

According to the welding technology, it can be divided into automatic welding and manual welding. Automatic welding generally adopts submerged arc welding and plasma welding, and manual welding generally adopts argon arc welding.

Classification of stainless steel welded pipe

According to the weld form, it is divided into straight seam welded pipe and spiral welded pipe.

According to the purpose, it is divided into general welded pipe, heat exchanger pipe, condenser pipe, galvanized welded pipe, oxygen blown welded pipe, wire casing, metric welded pipe, idler pipe, deep well pump pipe, automobile pipe, transformer pipe, electric welding thin wall Tubes, Electric Welded Shaped Tubes and Spiral Welded Tubes