In large-scale infrastructure and marine engineering projects, steel pipe piles are not simply structural components—they are high-risk, high-value procurement items. In 2026, buyers are under increasing pressure to balance technical compliance, delivery reliability, and total lifecycle cost.

At United Steel Industry, we work closely with global EPC contractors, infrastructure developers, and marine engineering firms, supporting steel pipe pile projects from technical review to final delivery. This buyer-focused guide outlines how procurement teams can make informed, risk-controlled purchasing decisions.

What Buyers Should Know About Steel Pipe Piles

From a buyer’s perspective, steel pipe piles are engineered products, not standard inventory items. Key parameters—such as outer diameter, wall thickness, steel grade, welding method, and corrosion protection system—directly affect pricing, lead time, and installation performance.

United Steel Industry supports customized piling solutions, ensuring each specification aligns with project drawings, soil conditions, and applicable standards.

Choosing the Right Pipe Type: Cost vs. Reliability

- Seamless Steel Pipe Piles

Uniform structure with no weld seam

Higher cost, lower weld-related risk

Used in critical or fatigue-sensitive foundation zones

- LSAW Steel Pipe Piles

High dimensional accuracy

Strong weld integrity and inspection control

Common in permanent bridge and offshore foundations

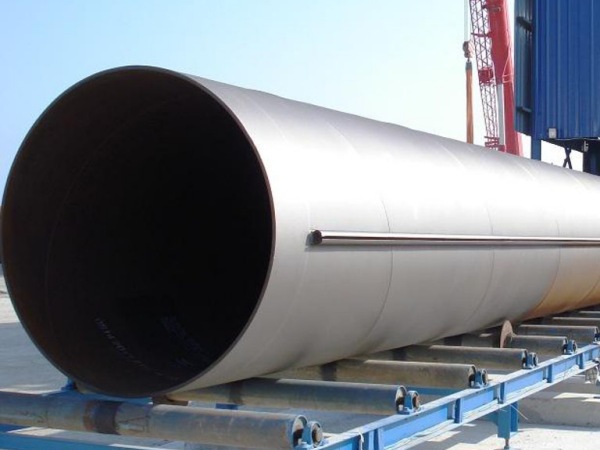

- SSAW Steel Pipe Piles

Cost-effective for large-volume projects

Flexible diameter and length production

Widely used in marine, port, and coastal piling

United Steel Industry Insight: For most large-scale piling projects, SSAW steel pipe piles provide the best cost-to-performance ratio when manufactured under strict quality control.

Standards and Certifications Buyers Must Verify

Reputable suppliers, including United Steel Industry, ensure steel pipe piles comply with internationally recognized standards such as:

ASTM A252 – Foundation piling

API 5L (Gr. B, X42–X70) – Structural and offshore use

EN 10219 / EN 10210 – European structural standards

GB/T 9711, GB/T 3091 – Project-based or regional supply

Buyers should always request EN 10204 3.1 Mill Test Certificates and corresponding NDT documentation.

Corrosion Protection: A Buyer’s Cost Control Tool

Corrosion protection significantly influences service life and maintenance cost, especially in marine and aggressive soil environments.

United Steel Industry commonly supplies steel pipe piles with:

3LPE or 3LPP external coatings

Internal epoxy coating options

Concrete-filled piles for enhanced durability

Compatibility with cathodic protection systems

Buyer recommendation: Clearly define coating thickness, standards, and inspection scope in the purchase order.

How United Steel Industry Supports Buyers in 2026

Procurement teams partnering with United Steel Industry benefit from:

Engineering support during specification confirmation

Stable production capacity for large-volume piling orders

In-house quality inspection and traceability control

Flexible customization of length, bevels, and coatings

Export-ready documentation and logistics coordination

Our goal is to help buyers reduce technical risk and avoid downstream project delays.

Common Procurement Risks and How to Avoid Them

Undefined dimensional tolerances → Confirm OD, WT, straightness limits

Incomplete inspection scope → Specify UT, RT, hydrostatic testing

Coating damage during transport → Require proper packing and repair plans

Over-aggressive pricing → Assess supplier capability, not price alone

Early technical clarification with your supplier can prevent costly change orders later.

Conclusion

In 2026, successful steel pipe pile procurement requires a structured, buyer-centric approach. Price is important, but long-term project performance depends on material quality, standard compliance, corrosion protection, and supplier reliability. By working with experienced manufacturers like United Steel Industry, buyers can achieve both cost efficiency and engineering confidence.

FAQ:

Q1: Does United Steel Industry supply steel pipe piles for marine projects?

Yes, United Steel Industry provides steel pipe piles specifically designed for marine and coastal environments.

Q2: Can United Steel Industry customize pile length and coatings?

Yes, custom lengths, bevels, and corrosion protection systems are available based on project requirements.

Q3: Which standards does United Steel Industry commonly follow?

ASTM, API, EN, and GB standards are commonly supported, depending on project location.

Q4: Are quality inspection reports provided with each order?

Yes, full inspection and test documentation is supplied with steel pipe pile deliveries.

Q5: Is SSAW steel pipe suitable for permanent foundations?

Yes, when produced and coated correctly, SSAW pipes are widely used in permanent piling projects.