①Material introduction

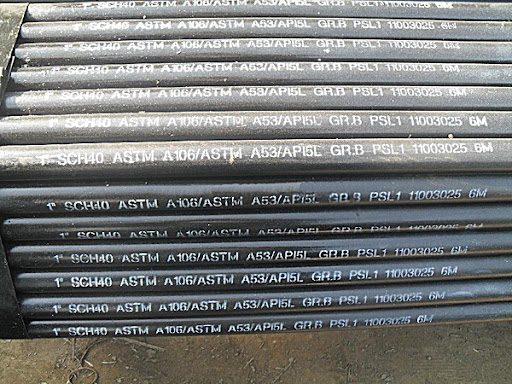

A106 GR.B seamless steel pipe is a high-quality steel pipe that is widely used in the petroleum, chemical, and boiler industries. The material has good mechanical properties. A106B American standard seamless pipe complies with the ASTM A106/A106M carbon steel seamless steel pipe standard for high-temperature operation, grade B. It can be seen from the ASME B31.3 chemical plant and petroleum refinery piping standards: A106 American standard seamless pipe material operating temperature range: -28.9~565℃ ;

specifications: 3/8"-30"*SCH5-XXS (ASME B36.10M standard)

ASTM A106 Seamless carbon steel pipe for high temperature use

chemical composition

| Grade | A | B | C |

| C | 0.25 | 0.30 | 0.35 |

| Mn | 0.27-0.93 | 0.29-1.06 | 0.29-1.06 |

| P | 0.035 | 0.035 | 0.035 |

| S | 0.035 | 0.035 | 0.035 |

| And | ≥0.10 | ≥0.10 | ≥0.10 |

| Cr | 0.40 | 0.40 | 0.40 |

| With | 0.40 | 0.40 | 0.40 |

| Mo | 0.15 | 0.15 | 0.15 |

| In | 0.40 | 0.40 | 0.40 |

| IN | 0.08 | 0.08 | 0.08 |

2.Cr+Cu+Mo+Ni+V shall not exceed 1%

Tensile properties

| Tensile properties | Grade A | Grade B | Grade C | |||

| Tensile strength , min, psi [MPa] | 48 000 [330] | 60 000 [415] | 70 000 [485] | |||

| Yield strength , min, psi [MPa] | 30 000 [205] | 35 000 [240] | 40 000 [275] | |||

| Elongation 2 in. [50 mm], min, %: | portrait | Horizontal | portrait | Horizontal | portrait | Horizontal |

| Suitable for transverse strip experiments and all small-size full-section experiments | 35 | 25 | 30 | 16.5 | 30 | 16.5 |

| Standard round test, 2-in. [50-mm] gauge length | 28 | 20 | twenty two | 12 | 20 | 12 |

| Longitudinal strip experiment | Note | Note | Note | |||

| For transverse strip testing , the percentage reduction from the basic minimum elongation for each 1.32-in. [0.8-mm] reduction in wall thickness less than 5⁄16 in. [7.9 mm ] | 1.25 | 1.00 | 1.00 | |||

Note:

The minimum elongation in2 in. [50 mm] shall be determined by the following equation:

e = 625000A0.2 / U 0.9 for SI units, and

e = 1940A0.2 / U 0.9 for inch-pound units