(1) Definition:

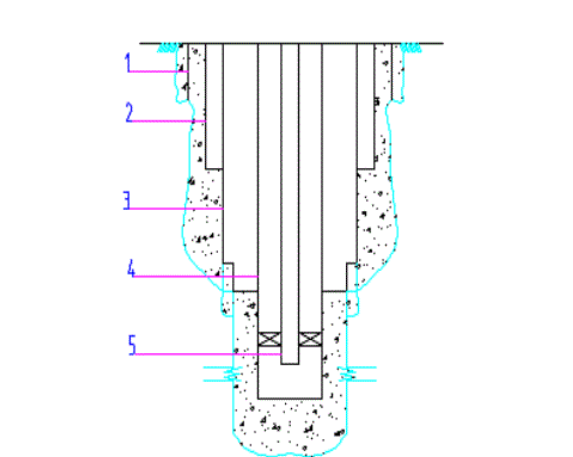

Petroleum casing is a steel pipe used to support the walls of oil and gas wells to ensure the normal operation of the entire oil well after the drilling process and completion. Each well uses several layers of casing according to different drilling depths and geological conditions. Cement cementing is used after the casing is lowered into the well. Unlike oil pipes and drill pipes, it cannot be reused and is a one-time consumable material. Therefore, the consumption of casing accounts for more than 70% of all oil well pipes. Casing can be divided into: conduit, surface casing, technical casing and oil layer casing according to the usage.

(2) Classification:

Different types of casing used in the oil extraction process: Surface oil casing - protects the drilling well from being polluted by shallow water and shallow gas layers, supports wellhead equipment and maintains the weight of other layers of casing. Technical Oil Casing - Separate the pressure of different layers so that the drilling fluid can flow normally and protect the production casing so that anti-burst devices, leak-proof devices and liners can be installed in the drilling. Reservoir Oil Casing (Production Casing) - Conducts oil and gas from subsurface reservoirs, protects drilling wells, and separates drilling mud layers. When produced, oil casing typically has an outer diameter of 114.3mm to 508mm.

① Guide sleeve:

mainly used for drilling in oceans and deserts to separate seawater and sand to ensure smooth drilling. The main specifications of this layer of casing are: Ø 762mm (30in ) × 25.4mm , Ø 762mm (30in) × 19.06mm.

② Surface casing:

It is mainly used for the first spud, drilling the soft stratum on the surface to the bedrock. In order to seal this part of the stratum from collapse, it needs to be sealed with the surface casing. The main specifications of the surface casing: 508mm(20in), 406.4mm(16in), 339.73mm(13-3/8in), 273.05mm(10-3/4in), 244.48mm(9-5/8in), etc. The depth of the lower pipe depends on the depth of the soft formation, generally 80~1500m. The external pressure and internal pressure it bears are not large, and K55 steel grade or N80 steel grade is generally used.

③Technical casing:

Used in the drilling process of complex formations. When encountering complex parts such as collapsed layers, oil layers, gas layers, water layers, lost circulation layers, and salt-gypsum layers, technical casings are required to be sealed, otherwise drilling cannot proceed. Some wells have deep and complex formations, and the depth of drilling reaches several thousand meters. This kind of deep well requires several layers of technical casing, which has high requirements on mechanical properties and sealing performance, and the steel grades used are also high. Most of them use N80 and P110 steel grades, and some deep wells also use Q125 or even higher non-API steel grades such as V150. The main specifications of technical sleeves are: 339.73mm(13-3/8in), 273.05mm(10-3/4in), 244.48mm(9-5/8in), 219.08mm(8-5/8in), 193.68mm (7- 5/8in) , 177.8mm(7in) etc.

④ Oil layer casing:

When drilling to the target layer (oil and gas-bearing layer), the oil layer casing is required to seal all the oil and gas layers and the upper exposed formation, and the inside of the oil layer casing is the oil pipe. Reservoir casing has the deepest running depth among all kinds of casing, and its mechanical properties and sealing performance requirements are also the highest. The steel grades used include K55, N80, P110, Q125, V150, etc. The main specifications of oil layer casing are: 177.8mm (7in), 168.28mm (6-5/8in), 139.7mm (5-1/2in), 127mm (5in), 114.3mm (4-1/2in), etc.

(3) The oil casing is the lifeline to maintain the operation of the oil well. Due to the different geological conditions, the downhole stress state is complex, and the combined effects of tension, compression, bending and torsional stress act on the pipe body, which puts forward higher requirements on the quality of the casing itself. Once the casing itself is damaged for some reason, it may lead to a reduction in production of the entire well, or even scrap it.

According to the strength of the steel itself, the casing can be divided into different steel grades, namely J55, K55, N80, L80, C90, T95, P110, Q125, V150, etc. The specifications are mainly 139.77.72R-2, 177.89.19R-2, 244.58.94R-2, 244.510.03R-2, 244.511.05R-2, etc. There are three types of length specified by API: R-1 is 4.88-7.62m, R-2 is 7.62-10.36m, and R-3 is 10.36m or longer. Different well conditions and well depths require different steel grades. In a corrosive environment, the casing itself is also required to have corrosion resistance. In places with complex geological conditions, the casing is also required to have anti-collapse performance. Processing form of casing end: short round thread, long round thread, partial trapezoidal thread, special buckle, etc. Used in oil well drilling, it is mainly used to support the well wall during the drilling process and after the well completion, so as to ensure the drilling process and the normal operation of the entire oil well after the well completion.

(3) Performance:

The solution to the poor toughness of the oil casing is to adopt the method of rapid cooling after tempering to avoid high temperature brittleness and obtain toughness. 2. The sub-temperature quenching method can effectively improve harmful elements and impurities and improve toughness through incomplete austenitization of steel types. The first method has relatively strict requirements on heat treatment equipment and requires additional costs. Low temperature quenching is lower than the conventional temperature, which reduces the stress of quenching, thereby reducing the deformation of quenching, which ensures the smooth operation of heat treatment production and provides good raw materials for subsequent wire processing.

(4) Note:

In view of the accelerated effect of mechanical abrasion on the corrosion of oil casing, it is recommended to add a rubber ring on the tubing coupling or add a centralizer to the serious part of the well deviation to avoid scratches on the tubing during operation and water injection Sleeve and One Side Contact Sleeve

Common Specifications for Casing

|

Outside Diameter |

Theoretical Weight |

Wall Thickness |

Inside Diameter |

Flow Diameter |

Coupling Outside |

Thread Type |

Steel Grade |

Length |

|

139.7 |

20.85(0.244) |

6.20(0.244) |

127.3(5.012) |

124.1(4.887) |

153.7 |

round thread Ladder thread |

j55 |

8m-12m |

|

177.8 |

25.52917.00) |

5.87(0.231) |

166.1(6.538) |

162.9(6.413) |

194.5 |

round thread Ladder thread |

j55 |

8m-12m |

|

219.1 |

35.75(24.00) |

6.71(0.264) |

205.7(8.093) |

202.5(7.972) |

244.5 |

round thread Ladder thread |

j55 |

8m-12m |

|

244.5 |

48.11(32.30) |

7.92(0.312) |

228.7(9.001) |

244.7(8.845) |

269.6 |

round thread Ladder thread |

j55 |

8m-12m |

|

273.0 |

48.78(32.75) |

7.09(0.279) |

258.9(10.192) |

254.9(10.035) |

298.5 |

round thread Ladder thread |

j55 |

8m-12m |

|

339.7 |

71.50(48.00) |

8.38(0.330) |

322.9(12.715) |

319.0(12.559 |

365.1 |

round thread Ladder thread |

j55 |

8m-12m |

|

73.0 |

9.53(6.40) |

5.51(0217) |

62.00(2.441) |

59.61(2.347) |

88.9 |

round thread |

j55 |

8.5m-9.5m |

|

88.9 |

11.47(7.70) |

5.49(0.216) |

77.9(3.067) |

24.25(2.943 |

107.95 |

round thread |

j55 |

8.5m-9.5m |

|

114.3 |

18.77(12.60) |

6.88(0.271) |

100.5(3.957) |

97.37(3.833) |

132.08 |

round thread |

j55 |

8.5m-9.5m |

|

(4-1/2) |

(27.9-31) |

(5) Chemical composition: Casing steel grade and chemical composition

The steel grades of casing are H40, J55, K55, M65, N80, L80, C90, C95, T95, P110, Q125, V150.

H40 is the lowest steel grade and is rarely used in the market.

The yield strength of J55 and K55 belong to the same level, the difference between them is that the tensile strength of K55 is higher than that of J55.

N80 is divided into N80-1 and N80Q.

L80 is divided into L80-1, L80-9Cr and L80-13Cr.

C90 is divided into C90-1 and C90-2.

Q125 is divided into Q125-1, Q125-2, Q125-3 and Q125-4.

V150 is a non-API high-strength steel grade, mainly used in deep wells and ultra-deep wells.

See the table for API standard requirements on the chemical composition of the bushing. Like the oil pipe, the API standard is also a wide-ranging guidance document for the chemical composition of the casing, and each manufacturer has its own special grade for the casing.

Casing Chemical Composition

|

Steel Grade |

Type |

C |

M |

M |

C |

N Max |

C Max |

P Max |

S Max |

S max |

|

|

|

|

|

min |

Max |

Min |

Max |

Min |

Max |

min |

max |

|

|

|

|

|

|

|

|

J55 |

|

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

0.030 |

0.030 |

- |

|

N80 |

1 |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

0.030 |

0.030 |

- |

|

N80 |

Q |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

0.030 |

0.030 |

- |

|

L80 |

1 |

- |

0.43 |

- |

1.90 |

- |

- |

- |

- |

0.25 |

0.35 |

0.030 |

0.030 |

0.45 |

|

L80 |

9Cr |

- |

0.15 |

0.30 |

0.60 |

0.90 |

1.10 |

8.00 |

10.0 |

0.50 |

0.25 |

0.020 |

0.010 |

1.00 |

|

L80 |

13Cr |

0.15 |

0.22 |

0.25 |

1.00 |

- |

- |

12.0 |

14.0 |

0.50 |

0.25 |

0.020 |

0.010 |

1.00 |

|

C90 |

1 |

- |

0.35 |

- |

1.00 |

0.25 |

0.75 |

- |

1.20 |

0.99 |

- |

0.020 |

0.010 |

- |

|

C90 |

2 |

- |

0.50 |

- |

1.90 |

- |

NL |

- |

NL |

0.99 |

- |

0.030 |

0.010 |

- |

|

T95 |

1 |

- |

0.35 |

- |

1.20 |

0.25 |

0.85 |

0.40 |

1.50 |

0.99 |

- |

0.020 |

0.010 |

- |

|

T95 |

2 |

- |

0.50 |

- |

1.90 |

- |

- |

- |

- |

0.99 |

- |

0.030 |

0.010 |

- |

|

P110 |

|

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

0.030 |

0.030 |

- |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(1) N80 oil casing is an important equipment for oil drilling. Its main equipment also includes drill pipe, core pipe and casing, drill collar and steel pipe for small-diameter drilling. The domestic casing is made of hot-rolled or cold-drawn steel for geological drilling, and the steel grade is represented by "geological" (DZ).

(2) Oil casing calculation formula: (outer diameter - wall thickness)* wall thickness *0.02466=kg/m (weight per meter)