As societal development advances, seamless pipes have become a staple in a myriad of industries. Proper storage practices are crucial to extend their operational longevity. Let's explore the optimal storage protocols for ASTM A106 seamless steel pipes.

1. Storage Environment: It is imperative to keep these pipes in a location that is dry and well-ventilated, free from moisture and corrosive substances. Prolonged exposure to water or chemicals can expedite the corrosion process.

2. Physical Protection: Safeguard the pipes from any potential physical damage by keeping them away from sharp objects or rough surfaces. Utilize appropriate padding or support systems to prevent any compression or bending.

3. Temperature Control: The storage location should not be subject to extreme temperatures. High temperatures might cause the pipes to expand, which could result in damage, while low temperatures might lead to contraction and the risk of cracking.

4. Avoiding Direct Sunlight: Prolonged exposure to the sun's rays can hasten the aging process and reduce the overall lifespan of the pipes. Whenever possible, store them in a shaded location.

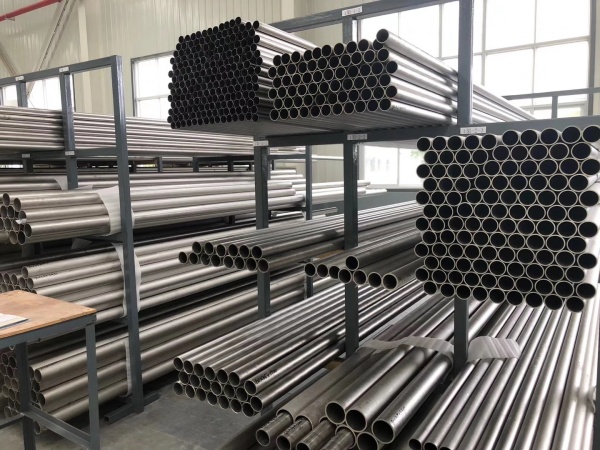

5. Stacking Considerations: Avoid stacking the pipes excessively high, as this can compromise stability and increase the likelihood of accidents, such as toppling, which may lead to damage.

6. Weight Distribution: When stacking, ensure an even distribution of weight across the pipes to prevent deformation due to localized pressure concentrations.

7. Maintaining Cleanliness: The storage area should be kept clean, free from dust and debris that could potentially contaminate the pipes.

8. Security Measures: For high-value pipes or in areas where theft is a concern, a secure storage facility is advisable.

9. Clear Labeling: Labeling the pipes with their specifications is beneficial for easy identification and retrieval when needed.

10. Inventory Management: Keeping an accurate and current inventory of stored pipes is essential for precise record-keeping and efficient stock tracking.

11. Routine Inspections: Conduct regular checks on the stored pipes for any signs of damage or corrosion, and address any issues without delay to prevent further damage.

12. Handling Practices: Use appropriate handling equipment and ensure that all personnel involved in handling and storage are well-trained in the correct techniques to prevent accidental damage to the pipes.