1) General Packaging Requirements

Packaging must ensure that both seamless and welded steel pipes are protected against loosening, deformation, and damage during normal handling, transportation, and storage.

Any specific requirements for packaging materials or methods from the buyer must be detailed in the contract. If not stipulated, the choice of packaging materials and methods will be left to the supplier's discretion.

2) Selection and Use of Packaging Materials

- All packaging materials must meet the applicable standards. If a packaging material is not mentioned or specified within this document, it should still be of a quality appropriate for its intended purpose. The choice of packaging materials may evolve with technological and economic developments.

- The design and selection of packaging materials should facilitate their reuse and recycling.

- Bundle packaging may utilize binding materials such as steel belts, steel wires, wire rods, or non-metallic flexible materials.

- Protective materials such as wood, metal, fiberboard, plastic, or other suitable materials may be used to prevent damage to the steel pipes and binding materials, based on buyer specifications.

- Protective packaging materials like kraft paper, vapor phase anti-rust paper, greaseproof paper, plastic film, sackcloth, plastic sheeting, and plastic sealing caps can be used for surface cleaning of steel pipes if required by the buyer.

- A protective coating, such as an anti-corrosion material, may be applied to the surface of the steel pipes if specified by the buyer. The method, thickness, and removability of the coating should be considered.

3) Bundling and Packaging Techniques

- Steel pipes with an outer diameter over 159mm or special-shaped pipes with a cross-sectional circumference exceeding 500mm may be shipped in bulk. Other pipes are recommended to be delivered in bundles.

- Steel pipe bundles must be securely bound using appropriate materials.

- Each bundle should consist of steel pipes from the same batch, except as permitted by product standards.

- The weight limit for each bundle of polished steel pipes, precision steel pipes, and cold-drawn stainless steel pipes is set at 2500kg, while other types of pipes have a limit of 5000kg. Different weight regulations may be agreed upon and stated in the contract.

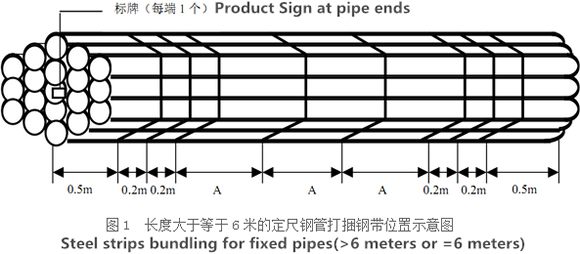

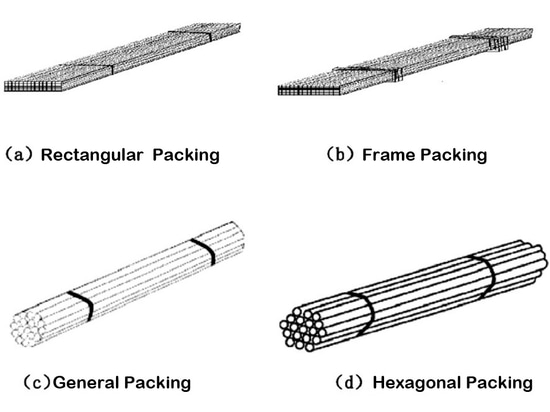

- Bundling can be performed using general, rectangular, frame, or hexagonal packaging, with bundling locations 300mm to 500mm from both ends of the pipes and evenly distributed. Alternative bundling forms may be negotiated.

- The number of bundles in each bundle should meet the specifications detailed in the table below:

|

Length of each bundle of steel pipes |

Minimum number of bundling lanes |

Length difference of steel pipes in each bundle |

|

≤3 |

2 |

-- |

|

>3-4.5 |

3 |

|

|

>4.5-7 |

4 |

≤1.0 |

|

>7-10 |

5 |

|

|

>10 |

6 |

≤1.5 |

- Steel wires used in bundling should be twisted into at least 2 strands, with additional strands required for larger outer diameters or heavier bundles.

- One end of each bundle should be flush, with the maximum length difference for steel pipes at the other end complying with specified regulations.

- Steel pipes of fixed lengths or multiple lengths should be bundled separately from those of non-fixed lengths. Short length steel pipes should also be bundled individually.

- Before bundling, polished and precision steel pipes should have their surfaces coated with anti-rust oil or another anti-rust agent, wrapped in moisture-proof paper, and then covered with sackcloth (or woven tape, plastic cloth) for added protection.

4) Container Packaging

- Following negotiations between the supplier and the buyer, detailed in the contract, certain types of steel pipes such as cold-drawn or cold-rolled seamless steel pipes with a wall thickness not exceeding 1.5mm, electric welded steel pipes with a wall thickness not exceeding 1mm, and surface-polished hot-rolled stainless steel pipes with surface roughness Ra not exceeding 3.2μm, may be packaged in durable containers like iron or wooden boxes.

- The maximum loadable weight of steel pipes per container should adhere to standard regulations, but can be adjusted through mutual agreement between the supplier and the buyer.

- During container loading, the interior walls should be lined with moisture-proof materials such as linoleum paper or plastic sheeting to protect the pipes. To prevent damage from movement, collision, or friction during transport, the steel pipes should be securely fixed inside the container using bundling, brackets, or similar methods. The container itself should be securely closed using steel belts, double-stranded steel wires, or other secure methods.

- Pipe joints, when shipped separately, should also be packed into containers, with the total weight of each container not exceeding 250kg.

5) Stainless Steel Pipe Packaging

- Thin-walled stainless steel pipes, where the wall thickness to outer diameter ratio is less than 3%, should either be bundled as illustrated in Figure 3 or packed in containers. Large-diameter stainless steel pipes should have supports added at both ends to prevent deformation during transport, loading, and unloading.

- Polished stainless steel pipes must be individually wrapped in plastic film before bundling. Cold-drawn or cold-rolled stainless steel pipes should be wrapped in at least two layers of sack cloth, woven tape, or plastic sheeting before bundling, with protective materials placed between the stainless steel pipes and the binding materials like steel strips or wires.

- Packaging methods for other stainless steel pipes should be tailored based on the pipe type, finishing process, dimensions, and the mode of transportation.

6) Thread and Pipe End Protection

Steel pipes with threaded ends must be fitted with thread protectors. Threaded welded steel pipes with a nominal diameter of less than 65mm used for low-pressure fluid transport are exempt unless specified by the buyer in the contract. Where required by the buyer, the supplier may deliver threaded steel pipes with a pipe joint already screwed on one end. Threads and machined surfaces on these pipes and their joints should be coated with thread grease, anti-rust oil, or other suitable anti-corrosion agents.

Pipe end protectors should be used on both ends of steel pipes with beveled ends if required by the buyer.