-

2025-12-30Product News

Will stainless steel pipe rust?

Does Stainless Steel Pipe Rust? Yes, stainless steel pipes can rust under certain conditions.

The belief that “stainless steel never rusts” is a common misunderstanding. Stainless steel is rust-resistant, not absolutely rust-proof. Its corrosion resistance depends on factors such as chemical composition, surface condition, service environment, and maintenance practices.

-

2025-12-23Product News

How to protect boiler tube from corrosion?

Boiler tubes are a specialized category of steel tubes and are predominantly manufactured as seamless steel pipes. Consequently, corrosion protection for boiler tubes must be implemented as a full-life-cycle strategy, covering design and material selection, surface protection, chemical water treatment, operational control, and shutdown maintenance.

-

2025-12-17Product News

Differences between spiral steel pipes and straight seam welded steel pipe

Spiral steel pipes and straight seam welded steel pipes are two of the most commonly used welded pipe products in large-scale pipeline and structural applications. While both rely on advanced welding technologies to achieve reliable mechanical performance, their manufacturing processes, welding methods, and application characteristics differ significantly. Understanding these differences is essential when selecting the most appropriate pipe type for a specific project.

-

2025-12-16Product News

Surface treatment methods for anti-corrosion spiral steel pipes

To ensure reliable anti-corrosion performance and extend the service life of spiral steel pipes, proper surface treatment before coating is essential. Different treatment methods serve different purposes, and in practice they are often used in combination to achieve the required cleanliness and surface roughness.

-

2025-12-15Product News

Connection methods of the industrial spiral steel pipes

In most applications, spiral steel pipes are connected by welding, as welded joints are cost-effective and suitable for the majority of project requirements. However, in certain projects, factors such as tight construction schedules, site constraints, operating conditions, or complex geographical environments may limit the use of welding. In such cases, alternative connection methods—such as threaded, flanged, socket, and grooved connections—are adopted. Below is an overview of the main non-welded connection methods used for spiral steel pipes and their characteristics.

-

2025-12-10Product News

How to choose the right small-diameter seamless steel pipe?

Selecting the right small-diameter seamless steel pipe requires considering factors such as operating environment, pressure level, temperature, corrosion resistance, structural requirements, and industry-specific standards. Below is a practical guide to choosing the appropriate specification based on different application scenarios.

-

2025-12-09Product News

Technical characteristics of double-sided submerged arc welded steel pipes

Double-sided submerged arc welded (SSAW) steel pipes are widely used in pipelines for oil, gas, water, and structural applications due to their stable performance and high manufacturing precision. Their production process offers significant technical advantages, especially for large-diameter and thick-walled pipe products. Below are the key technical characteristics that make these pipes reliable and versatile in demanding engineering environments.

-

2025-12-08Product News

Common defects in the welding zone of spiral submerged arc welded steel pipes

During the production of spiral submerged arc welded (SSAW) steel pipes, various welding zone defects may occur if process parameters, material conditions, or welding environments are not properly controlled. These defects can affect weld quality, structural integrity, and long-term performance. Below are the most common weld defects observed in SSAW pipes and their typical causes.

-

2025-12-01Product News

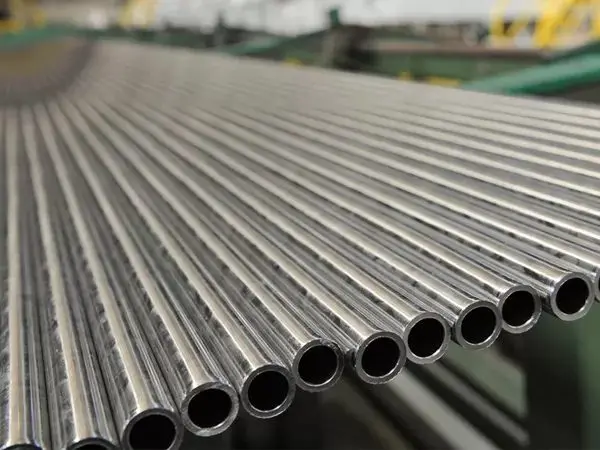

Manufacturing details of small-diameter precision seamless steel pipes

Small-diameter precision seamless steel pipes are produced with strict control over delivery conditions to achieve the required mechanical properties and dimensional accuracy. Different delivery states determine their performance and suitability for various industrial applications.

-

2025-11-26Product News

High-pressure seamless steel pipes for fertilizer equipment

High-pressure seamless steel pipes for fertilizer equipment are manufactured according to GB 6479 and designed for transporting high-temperature, high-pressure media in fertilizer and chemical plants. They operate reliably under –40~400°C and 10–30 MPa, ensuring safe long-term performance.

-

2025-11-25Product News

TP304 stainless steel seamless pipe

TP304 stainless steel seamless pipe is one of the most widely used austenitic stainless steel pipes in industrial systems, valued for its durability, corrosion resistance, and stable performance across demanding environments. Below is a clear and structured overview for quick reference.

-

2025-11-24Product News

Applications of 316 stainless steel seamless pipes

316 stainless steel seamless pipes are hollow, joint-free steel tubes manufactured from 316 stainless steel. Known for exceptional corrosion resistance and high-temperature performance, they are widely used in the chemical, petroleum, marine, pharmaceutical, and energy industries.