-

2025-07-22Product News

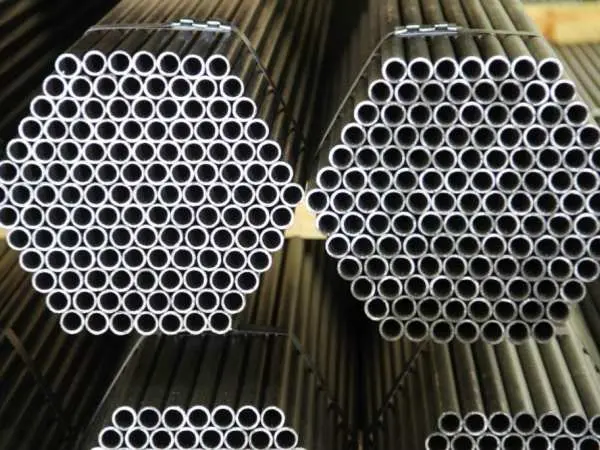

Overview of mechanical tube size

Mechanical tubes are a category of precision steel pipes specially designed for use in machinery manufacturing, engineering equipment, and industrial power or fluid transmission systems. These tubes are primarily supplied as seamless pipes or high-precision welded pipes, and are engineered to fulfill critical mechanical functions such as structural support, hydraulic fluid delivery, and power transmission.

-

2025-07-21Product News

X100QO seamless steel pipe details

X100QO seamless steel pipe is a high-performance steel product widely used across the oil, natural gas, and chemical industries, among other fields. Its seamless design enhances the safety and reliability of pipeline connections, enabling it to withstand high pressure and elevated temperatures, thereby ensuring the continuous and safe operation of industrial systems.

-

2025-07-17Product News

Introduction to L415M straight seam steel pipe

L415M straight seam steel pipe, also known as L415M straight seam welded steel pipe, is a high-strength pipeline product widely used in oil and natural gas transmission projects. This article will briefly introduce L415M straight seam steel pipe.

-

2025-07-16Product News

12Cr1MoV straight seam welded steel pipe

12Cr1MoV welded steel pipe is a high-performance alloy steel product designed to perform reliably under high-temperature and high-pressure conditions. Manufactured using a straight seam welding process, this pipe is widely used across power plants, petrochemical industries, and boiler systems, thanks to its optimized chemical composition and superior mechanical strength.

-

2025-07-15Product News

Advantages of ERW pipe in pipeline transportation

ERW stands for “electric resistance welded”. ERW pipes and tubes are manufactured by rolling metal and then welding it longitudinally across its length. ERW pipes have a welded joint in their cross-section. ERW pipe cold formed from a ribbon of steel pulled through a series of rollers and formed into a tube which is fused through an electric charge. It is mainly used for low/ medium pressure applications such as the transportation of water /oil. This article will briefly introduce advantages of ERW pipe in pipeline transportation.

-

2025-07-11Product News

ASTM A53 seamless pipe vs API 5L seamless pipe

ASTM A53 Seamless Pipe is a general-purpose carbon steel pipe defined by the American Society for Testing and Materials (ASTM). API 5L Seamless Pipe is a pipeline-grade steel pipe developed by the American Petroleum Institute (API), specifically designed for the transmission of oil, gas, and other energy resources over long distances. This article will briefly introduce key differences between astm a53 and api 5l seamless pipes.

-

2025-07-10Product News

Introduction to A106 seamless steel pipe

A106 seamless steel pipe stands out as a core product in the steel industry, attracting widespread attention for its durability, performance, and versatility. In this article, we’ll take a closer look at what makes A106 seamless steel pipe such a valuable asset in industrial applications.

-

2025-07-08Product News

Details of X70Q seamless steel pipe

X70Q seamless steel pipes are high-performance pipeline products widely used in petroleum, natural gas, chemical, and construction industries. Manufactured in compliance with API 5L (PSL2) standards for pipeline transportation of gas, oil, and water, and conforming to TSG D7002 pressure pipeline component type test rules, these pipes are engineered for reliability in demanding environments. This article will briefly introduce details of X70Q seamless steel pipe.

-

2025-07-03Product News

What is the corrosion resistance of chrome-plated seamless steel pipe?

Chrome-plated seamless steel pipes offer significantly improved corrosion resistance compared to standard seamless steel pipes, especially in harsh and aggressive environments. The chrome plating provides multiple layers of protection that extend the service life of the pipes and ensure their reliability in demanding applications. Below are the key advantages of chrome plating in enhancing corrosion resistance.

-

2025-07-01Product News

X65 fused epoxy powder anti-corrosion SSAW steel pipe

X65 fused epoxy powder-coated SSAW steel pipe represents a new generation of anti-corrosion pipeline technology, playing a vital role in industrial and infrastructure development. As global standards for corrosion resistance continue to rise, this material has gained increasing recognition across various industries. In this article, we explore the structural features, performance advantages, application fields, and market potential of X65 epoxy-coated SSAW pipes.

-

2025-06-30Product News

Details of X65M straight seam welded steel pipe

X65M straight seam welded steel pipe is a high-strength pipeline steel widely utilized in long-distance oil and natural gas transmission projects. Renowned for its excellent mechanical performance, weldability, and corrosion resistance, X65M steel pipe is becoming a critical material in both domestic and international pipeline construction markets. With the increasing global demand for energy infrastructure, its application prospects continue to expand.

-

2025-06-25Product News

API 5L GRB galvanized seamless steel pipes

API 5L GRB galvanized seamless steel pipe plays a crucial role in the transportation of fluids such as oil and natural gas. With its internal and external hot-dip galvanizing process, high zinc coating, and smooth, scratch-free surface, this pipe ensures both system safety and transport efficiency. Manufactured in strict accordance with API 5L standards, it offers superior corrosion resistance and fluid flow performance, making it an ideal choice for modern pipeline infrastructure.