-

2025-04-30Product News

Low medium and high pressure boiler pipe

Boiler pipes are essential components in steam boilers used for power generation and industrial heating. Based on their pressure-bearing capabilities, they are categorized into low-pressure, medium-pressure, and high-pressure boiler tubes. Each category differs significantly in terms of material selection, manufacturing standards, and usage scenarios.

-

2025-04-29Product News

The main production costs of precision seamless steel pipes

The production cost structure of precision seamless steel pipes is more complex than that of ordinary seamless pipes due to the additional finishing processes involved. United Steel Industry Co., Ltd. has outlined the main components contributing to the production costs of precision seamless steel pipes.

-

2025-04-29Product News

Precise control the wall thickness and diameter of seamless pipes

The precision control of wall thickness and diameter is crucial for ensuring the quality and performance of seamless steel pipes. Achieving this precision requires a combination of advanced technologies and methods. Below, United Steel Industry Co., Ltd. has summarized the main techniques for controlling the wall thickness and diameter of seamless pipes.

-

2025-04-28Product News

What to do if 316L thick-walled stainless steel pipe is corroded?

316L thick-walled stainless steel pipes are highly valued for their corrosion resistance, impact resistance, and high-temperature durability, making them commonly used in industries such as medicine, chemicals, food, light industry, chemical machinery, industrial pipelines, and mechanical parts. These thick-walled pipes are also essential in the production of exhaust systems and various basic pipelines. However, over time, these pipes may experience corrosion. So, what should be done if a 316L thick-walled stainless steel pipe becomes corroded?

-

2025-04-28Product News

Characteristics of non-magnetic stainless steel pipes

With the continuous development of science and technology, the functions of various equipment, instruments, and electrical appliances are constantly being upgraded. As a universal corrosion-resistant metal, stainless steel pipes have a wide range of applications. Many industries now require non-magnetic and demagnetized stainless steel products because magnetism can affect the performance of precision equipment and interfere with its detection accuracy. However, stainless steel is essential in many industries, so non-magnetic stainless steel materials have been developed, or magnetization and demagnetization processes are used to eliminate magnetism. The following introduces non-magnetic stainless steel pipes.

-

2025-04-27Product News

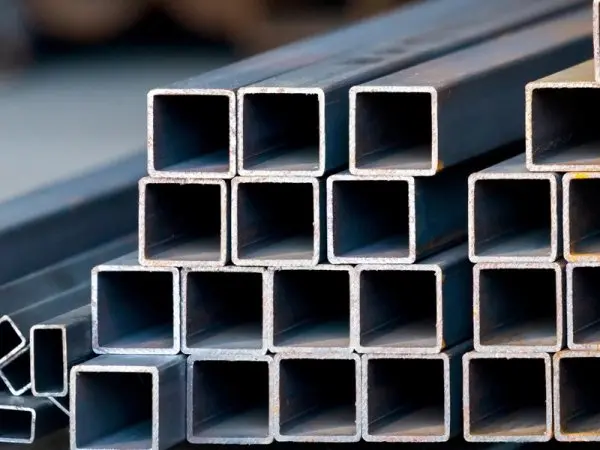

How are square seamless pipes used in the construction industry?

Square seamless pipes are becoming increasingly prominent in the construction sector, particularly in modern architectural designs. Renowned for their outstanding mechanical properties, structural stability, and aesthetic appeal, square steel pipes have become an essential material in building structures. Below are seven major application areas for square seamless steel pipes within the construction industry.

-

2025-04-27Product News

Carbon steel seamless pipe manufacturer and supplier in China

Carbon steel pipes (CS pipes) are essential components across various industries. United Steel Industry Co., Ltd is a leading manufacturer, exporter, and stockholder of carbon steel pipes in China. Dedicated to delivering high-quality steel pipe solutions, we proudly serve customers across the globe. With extensive expertise in carbon steel pipe manufacturing, our products are widely utilized in industries such as oil and gas, solar energy, water transportation, and construction worldwide.

-

2025-04-25Product News

316 stainless steel pipe inner wall coating

In both industrial and civil sectors, 316 stainless steel pipes are widely used due to their excellent corrosion resistance, high strength, and good processability. However, in certain extreme environments or applications with extremely high purity requirements, the inherent performance of 316 stainless steel may still fall short. In such cases, applying a coating to the inner wall becomes a key solution to enhance performance and expand the pipe’s usability across industries.

-

2025-04-24Product News

Hot-rolled seamless steel pipe specification list

Hot-rolled seamless steel pipe is a widely utilized material across various industries, including petroleum, chemical processing, manufacturing, power generation, and construction. Known for its excellent mechanical strength and corrosion resistance, it effectively meets the demands of a wide range of applications. The specifications of hot-rolled seamless pipes primarily refer to parameters such as outer diameter, wall thickness, and length, which vary based on project requirements.

-

2025-04-24Product News

How to choose seamless stainless steel pipes for industry?

In the dynamic and diverse steel market, seamless stainless steel pipes have gained widespread application across industries such as petroleum, chemical processing, medical, and food production due to their exceptional corrosion resistance, high strength, and excellent workability. However, with a wide variety of products available, accurately selecting pipes that align with specific project requirements has become a key concern for engineers and procurement professionals.

-

2025-04-23Product News

Processing technology for stainless steel precision tubes

The manufacturing process of stainless steel precision tubes is intricate and involves multiple stages to ensure high dimensional accuracy, excellent surface quality, and enhanced mechanical performance. This article will briefly introduce processing technology for stainless steel precision tubes.

-

2025-04-23Product News

API 5L Grade B seamless steel pipe comprehensive analysis

API 5L Grade B seamless steel pipe is a widely used pipeline product in the oil and gas industry. It adheres to the API 5L standard established by the American Petroleum Institute (API), where “L” stands for “Line” pipe. This standard applies to both seamless and welded steel pipes, with Grade B being one of the commonly used grades due to its balanced mechanical properties and excellent weldability. Here's an overview of API 5L Grade B seamless steel pipe.