-

2025-05-21Product News

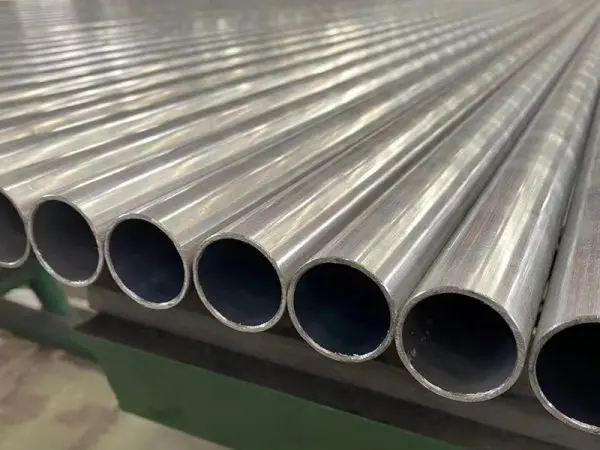

316 stainless steel pipe purchasing precautions

316 stainless steel pipe is one of the most commonly used austenitic stainless steel pipes. In addition to its superior corrosion resistance, 316 stainless steel pipe features excellent toughness and weldability. It can be cold-worked, is non-toxic, and meets hygienic standards. Common manufacturing standards include the Chinese GB/T 14976 and the American ASTM A312. With a wide range of specifications available, this pipe is commonly used for fluid transport and structural support across various industries.

-

2025-05-20Product News

Can precision tubes be bent?

As a high-precision, high-strength pipe material, precision tubes are extensively applied in industries such as machinery, chemicals, automotive, and construction. A common question among users is: Can precision tubes be bent? The answer is yes—however, due to their tight dimensional tolerances and superior mechanical strength, proper equipment, techniques, and process control are essential to ensure successful and high-quality bending.

-

2025-05-20Product News

Top 3 insulation boiler tube coatings

Boiler tubes, typically made from seamless steel pipes, are designed to withstand extreme heat and pressure. However, prolonged exposure to high-temperature, high-pressure, and corrosive conditions makes protective coatings essential for ensuring long-term performance and reliability. Unlike conventional household paints, boiler tube coatings must be specialized, industrial-grade materials that enhance corrosion resistance and thermal insulation, thereby extending service life and maintaining the stable operation of boiler systems.

-

2025-05-19Product News

Quality standards for seamless precision tube

The quality standards for seamless precision tubes encompass several critical aspects, each of which plays a key role in ensuring the performance, reliability, and safety of these tubes in various applications. The following outlines the key quality criteria.

-

2025-05-19Product News

Hydraulic tubes vs mechanical tubes

Although hydraulic tubes and mechanical tubes are both industrial steel tubes, they serve different roles in various industrial applications due to their distinct performance requirements and application scenarios. Despite having notable differences in materials, manufacturing processes, performance standards, and usage, they can sometimes be used interchangeably depending on the specific needs. Below is a detailed comparison between the two。

-

2025-05-16Product News

Introduction to corrosion resistance of boiler tubes

Boiler tubes, like arteries in the human body, play a crucial role in transporting heat energy in industrial systems. Depending on their manufacturing process, they are classified into seamless and welded types. Based on operating temperature, they are further divided into general boiler tubes and high-pressure boiler tubes. Among all performance metrics, corrosion resistance stands out as the “lifeline” of boiler tubes—critical to ensuring equipment safety, extending service life, reducing downtime, and enhancing operational efficiency.

-

2025-05-16Product News

Seamless and welded stainless steel mechanical tube

Stainless Steel (SS) Mechanical Tube refers to high-precision, high-strength stainless steel tubing manufactured through cold rolling, cold drawing, precision welding, and other finishing processes. These tubes are primarily used as load-bearing mechanical components, moving parts, or functional pipelines in industrial machinery and equipment. Unlike decorative stainless steel tubes or low-pressure fluid delivery pipes, mechanical tubes emphasize dimensional accuracy, mechanical performance, and surface quality to meet the rigorous demands of structural strength, wear resistance, and mobility under specific working conditions.

-

2025-05-15Product News

A335P22 seamless steel pipe

As a vital material in modern construction and engineering, steel pipe plays an indispensable role across numerous industries. Among these, the A335P22 seamless steel pipe, known for its exceptional properties, has garnered significant attention.

-

2025-05-15Product News

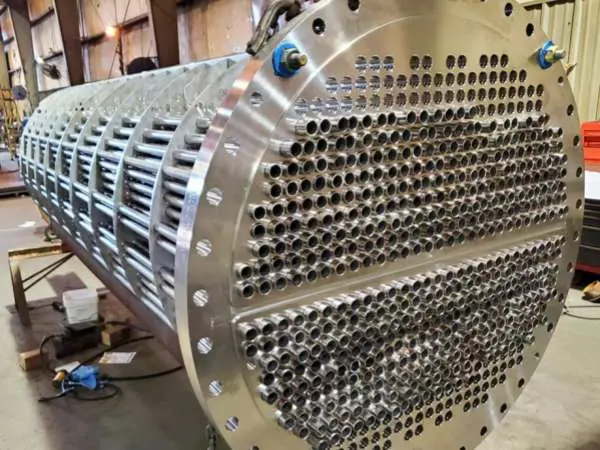

Seamless vs welded stainless steel heat exchanger tubes

This is a common question in industrial design and manufacturing. Both seamless and welded stainless steel heat exchanger tubes offer distinct advantages and limitations. The right choice depends on specific application needs and operating conditions.

-

2025-05-14Product News

Seamless-like stainless steel welded pipes

Stainless steel welded pipes are indispensable in both modern industry and daily life. From petroleum and chemical engineering to food processing, medical equipment, building structures, and automotive manufacturing, these pipes are everywhere. As technology advances and market expectations rise, the demand for higher-performance stainless steel welded pipes continues to grow. In response, “seamless-like” stainless steel welded pipes have emerged, offering unique advantages and gradually reshaping the market for traditional welded pipes.

-

2025-05-14Product News

Details of ASTM A312 TP310S stainless steel pipe

ASTM A312 TP310S stainless steel pipes are widely recognized high-performance materials, extensively used across industrial sectors—particularly in environments involving high temperatures, high pressure, and corrosive conditions. As a member of the austenitic stainless steel family, TP310S offers exceptional resistance to oxidation and corrosion, making it ideal for demanding applications.

-

2025-05-13Product News

Introduction to SA210C seamless pipe

SA210C seamless pipe, conforming to the ASME SA-210M standard, is a medium-carbon steel pipe designed specifically for boilers and superheaters. It holds a critical role in various industries, particularly in the manufacturing of boiler tubes. Below is a detailed overview of the SA210C seamless pipe.