-

2025-05-13Product News

Performance analysis of 316 stainless steel pipe at high temperature

316 stainless steel pipe plays an indispensable role in critical industries such as chemical processing, pharmaceuticals, and marine engineering due to its outstanding high-temperature resistance. It adheres strictly to the ASTM A240 standard, with a chemical composition of 16–18% chromium (Cr), 10–14% nickel (Ni), and 2–3% molybdenum (Mo). This alloy formulation enables the formation of a stable passivation film in high-temperature environments, while offering excellent resistance to corrosion and oxidation.

-

2025-05-12Product News

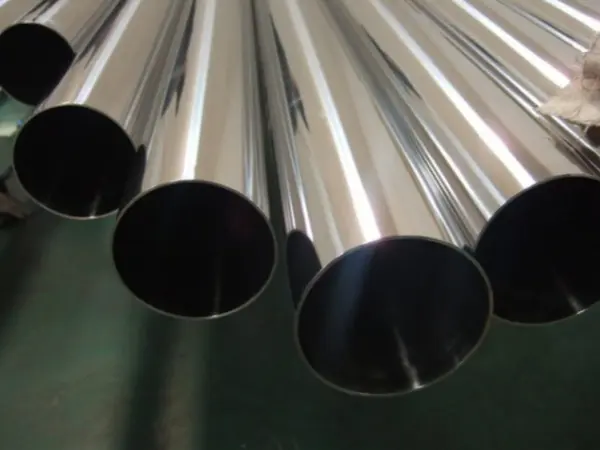

Introduction to 304 precision seamless tube

The 304 precision seamless tube is a high-precision seamless pipe manufactured primarily from 304 stainless steel. Renowned for its excellent surface quality and tight dimensional tolerances, it is widely used in industries requiring high precision and performance—such as chemical processing, food and beverage, pharmaceuticals, electronics, aerospace, and machinery manufacturing. As a widely used austenitic stainless steel, 304 offers superior corrosion resistance and formability, making it ideal for both pipeline systems and structural applications.

-

2025-05-12Product News

6 key production steps for high-pressure boiler tube

This article will briefly introduce 6 key production steps for high-pressure boiler tube.

-

2025-05-09Product News

Carbon steel elbow water pressure test

Carbon steel elbows (CS elbows) are vital components in pipeline systems, primarily used to alter the direction of fluid flow. Their sealing integrity and pressure resistance are crucial to maintaining system safety. To ensure they can withstand operational conditions without leaking or rupturing, water pressure testing is routinely conducted. This process serves as a critical quality control measure, verifying the performance and structural integrity of the elbows before they are put into service. This article outlines the standard methods, step-by-step procedures, and key precautions for conducting water pressure tests on carbon steel elbows, along with an overview of its importance.

-

2025-05-09Product News

Things to note when purchasing stainless steel elbows

Stainless steel elbows are essential pipe fittings widely used in pipeline systems to alter the direction of flow. They are commonly found in industries such as petroleum, chemicals, electric power, and construction. These components are typically manufactured through either cold bending or hot bending processes. Cold bending is more suitable for pipes with smaller diameters and thinner walls, offering a smooth surface finish and high dimensional accuracy. In contrast, hot bending is ideal for pipes with larger diameters and thicker walls, as elevated temperatures improve the material’s plasticity, making it easier to shape.

-

2025-05-08Product News

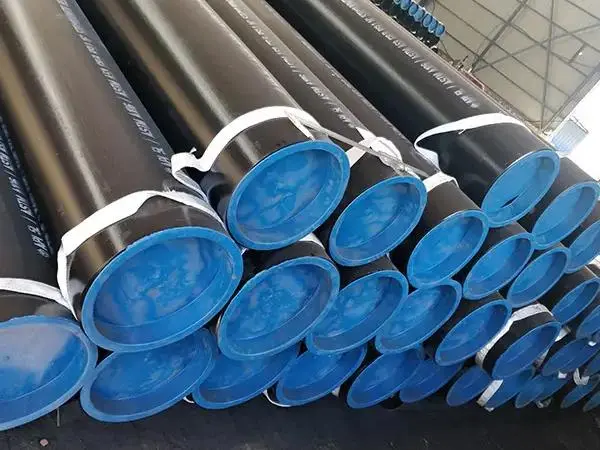

Carbon steel No. 20 seamless pipe

In modern industry, seamless steel pipes play a vital role thanks to their unique properties and broad range of applications. Among the various grades available, carbon steel No. 20 seamless steel pipe has earned widespread recognition for its excellent performance and adaptability. This article provides an in-depth overview of the material characteristics, mechanical properties, weldability, and application fields of carbon steel No. 20 seamless pipes, offering readers a comprehensive understanding of this essential industrial material.

-

2025-05-08Product News

All about 10# seamless carbon steel pipe

In the expansive world of industrial materials, the 10# seamless carbon steel pipe stands out as a vital pillar across numerous sectors. Renowned for its robust performance and diverse applications, this pipe type not only supports the infrastructure of industrial progress but also continues to evolve through technological advancements. This article delves into the core characteristics, manufacturing process, application scope, and innovative uses of 10# seamless carbon steel pipe—uncovering why it remains a reliable backbone in today’s industrial landscape.

-

2025-05-07Product News

316L stainless steel pipe welding process requirements

The welding process plays a critical role in determining the final quality and performance of 316L stainless steel pipes. As a low-carbon austenitic stainless steel, 316L offers excellent corrosion resistance and weldability—but only when proper techniques and parameters are applied. In this article, we’ll explore the essential welding requirements for 316L stainless steel pipes, including recommended welding methods, materials, parameters, and key technical precautions.

-

2025-05-07Product News

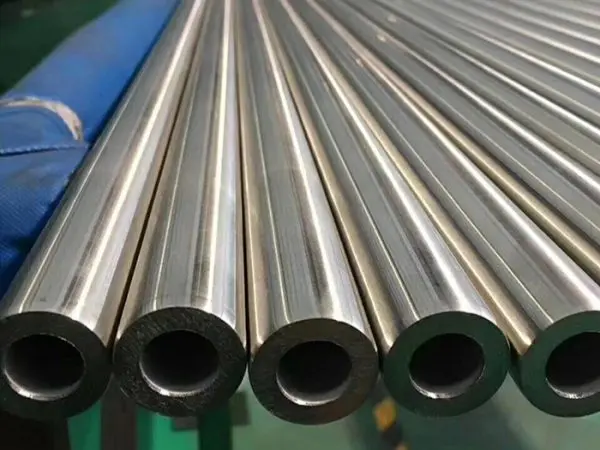

Precision steel pipe purchasing guide

When purchasing a precision steel pipe, it’s crucial to pay close attention to a variety of factors. Different types of precision steel pipes vary significantly in materials, performance, specifications, and applications. To ensure a successful purchase, you need to clearly define your needs, understand the available types, verify specification and quality standards, choose reliable manufacturers, and consider cost-effectiveness. With a thorough evaluation, you can select high-quality precision steel pipes that meet your operational requirements. Below are some key purchasing considerations.

-

2025-05-06Product News

The relationship between price and quality of stainless steel seamless pipes

There is a close connection between the price and quality of stainless steel seamless pipes. Generally, higher prices tend to reflect better quality, but the relationship is not absolute. A higher price does not always guarantee superior quality. To accurately evaluate the two, it is important to consider multiple factors. United Steel Industry Co., Ltd. summarizes the key points below.

-

2025-05-06Product News

HS code for precision steel tube

The HS code—short for Harmonized Commodity Description and Coding System—is a globally standardized system for classifying traded products. It was developed by the World Customs Organization (WCO) to facilitate international trade and streamline customs procedures. Below are commonly used HS codes for seamless precision tubes, typically classified based on their manufacturing process.

-

2025-04-30Product News

Mechanical properties of 316l stainless steel pipes

To ensure the quality and precision of deep-processing procedures such as bending, stamping, and drawing, the mechanical properties of 316L stainless steel pipes must not be overlooked. These properties directly influence the pipe’s performance during forming and its structural integrity in actual use.