-

2025-02-19Product News

Main application industry of hot rolled seamless steel pipes

Hot-rolled seamless steel pipes are extensively utilized across various industrial sectors due to their excellent mechanical properties, high pressure-bearing capacity, and cost-effectiveness. This article explores the primary industries where these pipes are most commonly applied.

-

2025-02-18Product News

How to purchase MS ERW pipes at a low price?

Purchasing MS ERW (Mild Steel Electric Resistance Welded) pipes at a low price requires a strategic approach that involves market research, supplier selection, understanding material specifications, and taking advantage of price fluctuations. Whether you're sourcing for industrial projects or long-term supply needs, these steps will help you secure the best deals while maintaining quality.

-

2025-02-18Product News

Cleaning techniques for equipment mechanical tubes

Pipe cleaning is a crucial step in the maintenance and operation of mechanical equipment, serving as a necessary guarantee for smooth production and reliable performance. Cleaning experts employ a variety of advanced cleaning techniques to ensure the efficient flow of mechanical tubes, preventing blockages and maintaining system integrity.

-

2025-02-17Product News

Precautions for packaging and transportation of 304 stainless steel pipes

304 stainless steel pipes come in various product types, finishes, sizes, and transportation methods, which require different packaging forms. These pipes are commonly used as product pipes, mechanical pipes, and decorative pipes, and undergo various processes such as forming, annealing, pickling, cold working, grinding, polishing, and decorative treatments. These factors lead to a wide range of sizes and processing types. Therefore, when purchasing or ordering, it's essential to consider the appropriate packaging, labeling, and shipping methods. Below are the key precautions for packaging and transporting 304 stainless steel pipes.

-

2025-02-17Product News

Carbon steel pipe vs stainless steel pipe in corrosion resistance

This article will briefly introduce carbon steel pipe vs stainless steel pipe in corrosion resistance.

-

2025-02-14Product News

Exploring the advantages and application of DN25 galvanized steel pipes

DN25 galvanized steel pipes are pipes with a nominal diameter of 25mm that have been coated with a layer of zinc. These pipes are commonly used in a variety of industries, including water supply, drainage systems, construction, and mechanical applications. Known for their durability, corrosion resistance, and strength, DN25 galvanized steel pipes are an essential component in many construction and industrial projects. The galvanizing process, which can be done through either cold plating or hot plating, helps to enhance the pipe’s resistance to corrosion.

-

2025-02-14Product News

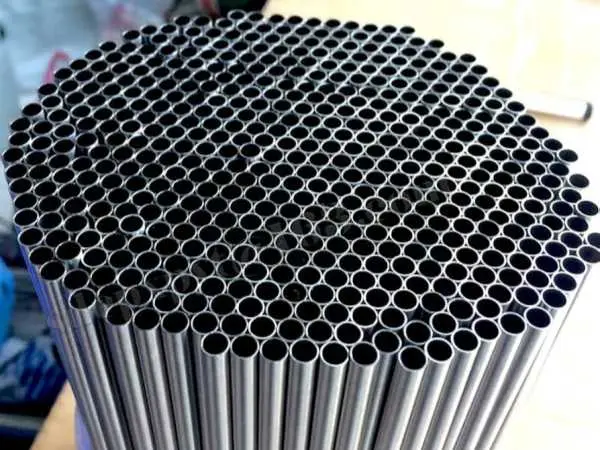

The inner diameter and aperture measurement method of precision steel pipes

In the production and inspection of precision steel pipes, aperture measurement plays a crucial role. There are several measurement methods available, each suitable for different accuracy levels and measurement requirements.

-

2025-02-13Product News

Exploring the characteristics and application fields of 100Cr6 seamless steel pipe

100Cr6 seamless steel pipe is a key product that has gained significant attention in the steel industry due to its distinct advantages and versatile applications. Let's take a closer look at the features of this steel pipe and explore its value across various industries.

-

2025-02-13Product News

Advantages and application value of Q355 seamless steel pipe

Q355 seamless steel pipe, a high-performance material, has become indispensable across various industries due to its remarkable properties and versatile applications. With superior mechanical characteristics and long-lasting durability, it offers significant advantages for a wide range of projects.

-

2025-02-12Product News

200 galvanized steel pipe - high-quality building tools

Steel pipes play a crucial structural role in the construction industry and are essential materials. Among the various types of steel pipes, the 200 galvanized steel pipe stands out due to its unique characteristics.

-

2025-02-12Product News

Introduction to DN165 galvanized steel pipe

With the development of the economy and technological advancements, the steel industry has become an essential and integral part of modern industry. Among various steel materials, galvanized steel pipes are widely used in construction, bridges, roads, pipelines, petrochemicals, and many other sectors. Here's an overview of the DN165 galvanized steel pipe.

-

2025-02-10Product News

Manufacturing process of carbon steel plates

Carbon steel plates are indispensable basic materials in various industrial sectors, widely used for their exceptional strength, versatility, and relatively low cost. This article will briefly introduce manufacturing process of carbon steel plates.