-

2024-11-19Product News

The advantages of prepainted galvanized steel coil

Prepainted galvanized steel coil is manufactured from hot-dip galvanized sheets, hot-dip aluminum-zinc plates, or electro-galvanized sheets. After undergoing surface pretreatment (such as chemical degreasing and conversion treatment), these coils are coated with layers of organic paint and cured through baking processes. The result is a steel product with a vibrant appearance and excellent material properties.

-

2024-11-19Product News

Steel coil manufacturing technology

Steel coil manufacturing involves a series of advanced processes designed to produce high-quality steel in various forms, such as hot-rolled, cold-rolled, or coated coils. These coils are widely used in construction, automotive, energy, and appliance manufacturing. Below is a detailed overview of the technologies and processes involved in steel coil manufacturing.

-

2024-11-18Product News

Introduction to SCH 40 galvanized seamless pipe

SCH 40 galvanized seamless pipe refers to a type of steel pipe with a Schedule 40 wall thickness that is also coated with a layer of zinc through galvanization. This combination makes the pipe durable, corrosion-resistant, and suitable for various structural, industrial, and fluid transportation applications.

-

2024-11-18Product News

How many types of galvanized seamless pipes are there?

Galvanized seamless pipes can be classified into different types based on the galvanizing process, intended application, and zinc coating method. Here’s an overview of the main types of galvanized seamless pipes.

-

2024-11-13Product News

Galvanized welded pipe production process

Galvanized welded pipes are widely used in various industries due to their strength, durability, and excellent corrosion resistance provided by a protective zinc coating. The production process of galvanized welded pipes involves several precise and well-coordinated steps that ensure the pipes meet high quality standards and perform reliably under different conditions. Here is a detailed look at each stage of the process.

-

2024-11-13Product News

Introduction to ERW galvanized steel pipe

ERW (Electric Resistance Welded) galvanized steel pipes are steel pipes with a protective zinc coating applied to enhance their resistance to corrosion. This coating ensures durability and longevity, making ERW galvanized pipes a reliable, versatile, and cost-effective solution for various industrial, commercial, and residential applications. These pipes are popular in fields like construction, agriculture, and plumbing due to their excellent corrosion resistance, structural strength, and ease of installation.

-

2024-11-12Product News

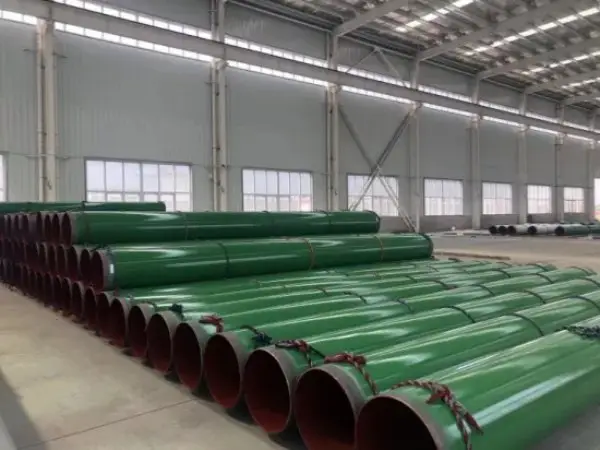

FBE coating pipe coating techniques

Fusion Bonded Epoxy (FBE) coating is widely used in pipe protection, particularly in industries where pipes are exposed to corrosive environments, such as oil, gas, and water industries. This type of coating forms a strong, corrosion-resistant layer that can extend the life of steel pipelines, significantly reducing maintenance costs and downtime. To achieve the desired protective layer, three main application techniques for FBE coating are used, each providing unique benefits depending on the specific requirements of the pipeline project. These methods include Electrostatic Spray, Fluidized Bed, and Rotary Atomization.

-

2024-11-12Product News

Advantages of FBE coated pipes

Fusion Bonded Epoxy (FBE) coated pipes offer several advantages, making them popular in industries requiring durable and corrosion-resistant piping. Here are the key benefits of FBE coated pipes.

-

2024-11-11Product News

Concrete coated pipe types and dimensions

Concrete coated pipes are commonly used in subsea environments and are manufactured in various dimensions and with multiple coating options to meet different environmental demands. These pipes can be customized with varying weights, thicknesses, and densities of concrete coatings, as well as additional anti-corrosion and insulation coatings to enhance their durability and performance underwater.

-

2024-11-11Product News

Referred standards of concrete coated pipe

When it comes to manufacturing and ensuring the quality of concrete coated pipes, adherence to a range of standards is essential. These standards guide not only the coating specifications but also the testing procedures and material properties required for optimal performance in challenging environments such as marine or underground pipeline systems. Below are the key standards that are commonly referenced in the production and inspection of concrete coated pipes.

-

2024-11-08Product News

How to distinguish the quality of FBE coated steel pipes?

To evaluate the quality of Fusion Bonded Epoxy (FBE) coated steel pipes, it is essential to assess several key factors that influence the coating's performance, durability, and protective qualities. Here are some critical methods for distinguishing the quality of FBE coated steel pipes.

-

2024-11-08Product News

Anti-corrosion epoxy powder coated steel pipe surface pretreatment requirements

To ensure the long-term durability and effectiveness of anti-corrosion epoxy powder coatings on steel pipes, proper surface pretreatment is essential. This process prepares the steel surface, enhancing coating adhesion and preventing rust or other forms of degradation that could weaken the coating’s protective properties. Here are the critical steps in the surface pretreatment process for epoxy-coated steel pipes.