-

2024-09-13Product News

Seamless pipe hs code introduction

Seamless pipework refers to pipes that are manufactured without weld seams or imperfections, providing exceptional strength and pressure integrity. These pipes are extensively used in industries such as oil and gas pipeline construction, but they also serve a wide range of other applications. In this article, we will explore the HS Code for seamless pipes, explain what this code represents, and discuss its significance in international trade. Additionally, we will examine the different types of seamless pipes, their advantages and disadvantages, and how to select the appropriate type for your specific application.

-

2024-09-13Product News

Introduction to seamless steel pipe weight calculation

Accurate weight calculations of seamless steel pipes are crucial for both industrial and commercial applications. These pipes are commonly used for transporting liquids, gases, and other materials, and their weight plays a significant role in determining the safety and efficiency of the systems they are part of. By properly calculating the weight of each pipe, engineers can ensure that the system can withstand the operational loads, environmental conditions, and other influencing factors. This article provides a detailed overview of the methods used to determine seamless pipe weight and highlights the potential risks of incorrect calculations.

-

2024-09-12Product News

Packaging and transportation methods of seamless carbon steel pipe

Proper packaging and transportation of seamless carbon steel pipes are essential to maintain their quality and prevent damage during handling. Whether for use in the construction, manufacturing, or other industries, careful attention must be paid to how these pipes are loaded, transported, and unloaded. Below are several key practices to ensure safe handling and transportation of seamless carbon steel pipes.

-

2024-09-12Product News

Pre-welding of welded steel pipes

Before performing the actual welding process, several critical steps must be taken to ensure the quality and integrity of the welded pipe. Pre-welding preparation is crucial for achieving optimal results, minimizing defects, and ensuring the safety and durability of the final product. Below are key factors to consider during the pre-welding stage.

-

2024-09-11Product News

International standards for RHS steel

RHS steel, often simply referred to as rectangular steel tubes, encompasses a series of standardized steel profiles designed for structural applications. Here's an overview of the international standards for RHS steel.

-

2024-09-11Product News

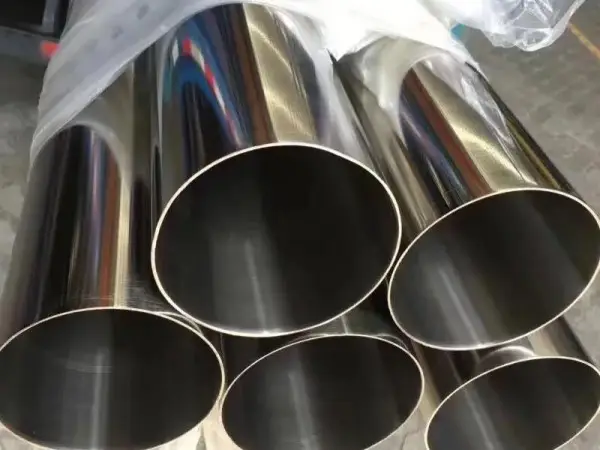

Advantages of stainless steel seamless pipe

Stainless steel seamless pipes are extensively used across various industries due to their numerous benefits. This article explores the advantages of stainless steel seamless pipes in different industrial applications.

-

2024-09-10Product News

Chromium plating and nickel plating for seamless steel pipes

Chromium plating and nickel plating are two commonly used surface treatment processes for seamless steel pipes. Both methods are applied to enhance the performance and appearance of steel pipes, providing additional protection against corrosion, wear, and environmental factors. This article will provide an overview of these two plating techniques, including their features, advantages, and common applications.

-

2024-09-10Product News

The uses of stainless steel square tubes

The stainless steel square tube is a hollow, square-shaped, lightweight thin-walled steel tube, commonly referred to as a steel cold-bent profile. Due to its strength, durability, and resistance to corrosion, stainless steel square tubes have become highly versatile and are widely used across various industries. This article explores the diverse applications of stainless steel square tubes.

-

2024-09-06Product News

Square steel tube forming method

Square steel tubes are formed using specific bending techniques that shape the tube according to desired structural requirements. These methods ensure precise forming and play a crucial role in the final mechanical properties of the tube. The two primary methods used are solid bending and air bending, each with its own set of advantages and challenges. Below is a detailed explanation of both techniques.

-

2024-09-06Product News

Classification of square steel tube

Square steel tubes are widely used in various industries due to their versatility and structural integrity. They can be categorized based on several factors, such as production process, material, production standards, cross-sectional shape, surface treatment, and their intended application. Below is a detailed breakdown of the different classifications.

-

2024-09-05Product News

How to construct and install thin-walled stainless steel seamless pipes?

Thin-walled stainless steel seamless pipes refer to pipes with a wall thickness to outer diameter ratio of no more than 6%, primarily used in building water supply systems. This article provides guidelines for the construction and installation of thin-walled stainless steel seamless pipes to ensure their durability and performance.

-

2024-09-05Product News

ERW steel pipes quality determining factors

The quality of ERW (Electric Resistance Welded) steel pipes is determined by several factors that influence their performance, durability, and overall suitability for various applications such as construction, water transmission, oil and gas pipelines, and mechanical structures. This article will briefly introduce ERW steel pipes quality determining factors.