-

2024-09-04Product News

Production technology of large diameter square and rectangular tubes

There are currently four primary processes for manufacturing large-size square and rectangular tubes.

-

2024-09-04Product News

Quality inspection steps for stainless steel seamless pipes

The quality inspection process for stainless steel seamless pipes involves a series of seven critical steps.

-

2024-09-03Product News

How are galvanized pipes produced?

Zinc is a widely used metal element known for its excellent corrosion resistance, making it a popular choice for anti-corrosion treatments across various industries. One of the most common products utilizing zinc is the galvanized pipe (GI Pipe), which is highly regarded for its durability and wide range of applications. Below is an overview of the production process of galvanized pipes.

-

2024-09-03Product News

Installation techniques for welded steel pipes

When installing welded steel pipes, following precise techniques ensures that the piping system is both durable and efficient. Proper preparation and adherence to standard procedures are essential to prevent leaks, ensure alignment, and maintain the structural integrity of the piping system. Below is a detailed guide on the installation techniques for welded pipes.

-

2024-09-02Product News

Factors affecting the yield strength of seamless pipe

The yield strength of seamless pipes is influenced by various external and intrinsic factors. Understanding these factors is crucial for optimizing the performance and reliability of these pipes in different applications. Below, we expand on the key factors that affect the yield strength of seamless pipes.

-

2024-09-02Product News

Factors that affect the durability of LSAW steel pipes

Longitudinal Submerged Arc Welded (LSAW) steel pipes are extensively utilized across various industries due to their superior strength and durability. However, the performance and longevity of these pipes can be affected by numerous factors. This article examines the critical aspects that influence the durability of LSAW steel pipes, focusing on the production process, material quality, environmental conditions, and maintenance practices that impact their lifespan and overall performance.

-

2024-08-30Product News

How does a pipe stand work?

A pipe stand is a support device used to hold and stabilize pipes during installation, welding, or maintenance. It ensures that the pipe remains in the desired position, preventing it from moving or sagging. Pipe stands are commonly used in construction, plumbing, and industrial applications where pipes need to be kept at a specific height or angle.

-

2024-08-30Product News

Understanding the pipe clamps

Pipe clamps are essential components in various industries, providing secure fastening and support for piping systems. These clamps are designed to hold pipes in place, ensuring stability and reducing the risks associated with pipe movement or vibration. Understanding the materials, features, and applications of pipe clamps is crucial for selecting the right type for specific needs.

-

2024-08-29Product News

Types of pipe clamps for piping and plumbing industry

Pipe clamps play a crucial role in supporting suspended pipes and can also function as clamped pipe shoes. These clamps are essentially bolted circular or semi-circular attachments that encircle a pipe and connect it to other components for stable support. By transferring the loads from the piping system to the structure, pipe clamps ensure proper alignment and security. There is a wide variety of pipe clamps available, each designed to meet specific needs.

-

2024-08-29Product News

Applications of steel screen pipe

Steel screen pipes are widely used in various industries due to their strength, durability, and versatility. These pipes are designed with a series of openings or perforations, which allow fluids to pass through while filtering out solid particles. Here are some key applications of steel screen pipes.

-

2024-08-28Product News

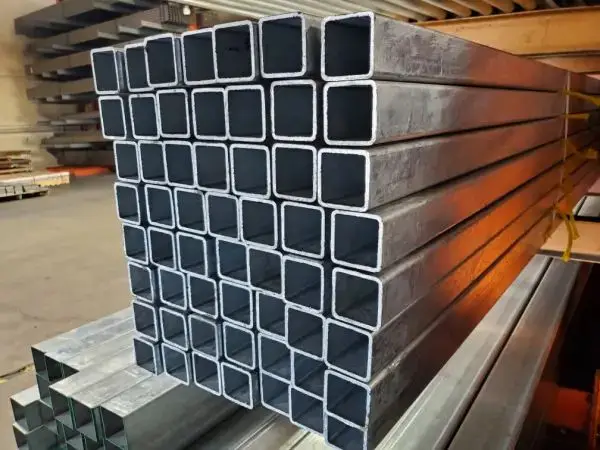

Non-metallic inclusions in square steel tubes

Square steel tubes, available in either Type A513 or A500 Grade B depending on size and wall thickness, are a versatile welded structural grade material. These tubes are ideal for various structural applications, general fabrication, and repair work. They are widely used in industrial maintenance, farm equipment, transportation, truck beds, trailers, frames, and more. This article will briefly introduce non-metallic inclusions in square steel tubes.

-

2024-08-28Product News

Rectangular steel tube surface defect detection

Surface defects of rectangular steel tubes include folding, rectangular tube pits, pockmarked surfaces, and bridge skin. This article introduces several methods for detecting surface defects in rectangular tubes.