-

2024-06-19Product News

The role of ERW steel pipes in different industries

Electric Resistance Welded (ERW) steel pipes, produced by longitudinally rolling and welding steel strips, are renowned for their seamless flow and joint strength, achieved through electric current heating. This makes them versatile and cost-effective for various industrial applications.

-

2024-06-19Product News

How to remove rust in stainless steel seamless pipes?

Stainless steel seamless pipes (SS seamless pipes) are not entirely immune to rust and can corrode under certain conditions. This article, brought to you by United Steel Industry, explains the reasons behind this phenomenon and how to address it effectively.

-

2024-06-18Product News

Advantages of PE coating steel pipe

PE (Polyethylene)coating steel pipes offer numerous advantages, making them a popular choice for various industrial and infrastructure applications. Here are the key benefits of using PE anti-corrosion steel pipes.

-

2024-06-18Product News

ASTM A789 seamless and welded stainless steel pipe

ASTM A789 covers both seamless and welded stainless steel pipes, primarily used for general corrosion-resisting and high-temperature service. These pipes are typically made from duplex and super duplex stainless steels, offering a combination of strength and corrosion resistance.

-

2024-06-17Product News

DIN 1629 seamless steel pipes

DIN 1629 is a German standard that specifies the requirements for seamless circular tubes made of non-alloy steel. These pipes are primarily used for general structural purposes and mechanical engineering applications. Unlike other standards that focus on high-temperature or high-pressure applications, DIN 1629 pipes are designed for use in moderate conditions where high strength and durability are still required.

-

2024-06-17Product News

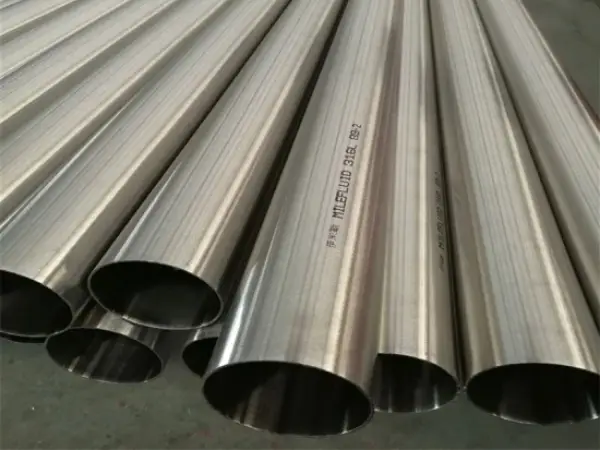

Why thick-walled 316 ss pipe is more corrosion-resistant than 304 ss pipe?

Thick-walled 316 stainless steel (SS) pipe is more corrosion-resistant than 304 stainless steel (SS) pipe due to its chemical composition, which includes the addition of molybdenum. Here’s a detailed explanation of why this difference in composition enhances the corrosion resistance of 316 SS compared to 304 SS.

-

2024-06-14Product News

Seam treatment of spiral welded pipe

Here's an overview of the seam treatment of spiral welded pipe.

-

2024-06-14Product News

Purpose and types of welded steel pipe

Welded steel pipes are categorized into various types based on their applications and manufacturing processes. These include general welded pipe, galvanized welded pipe, oxygen welding tube, metric system welded tube, transformer tube, welding thin wall pipe, and spiral welded pipe.

-

2024-06-13Product News

Seamless boiler pipe welding standards

Seamless boiler pipes are essential components used in high-pressure and high-temperature environments, such as in boilers and power plants. The welding standards for seamless boiler pipes ensure the integrity, safety, and performance of these pipes under such demanding conditions. Below are some key standards and considerations.

-

2024-06-13Product News

Standard length of welded steel pipe

Welded steel pipes, known for their high strength, corrosion resistance, and smooth surface, are made by welding various materials to meet diverse usage needs. These pipes are extensively used in construction, manufacturing, machining, and other industries. Common lengths for welded pipes are 6 meters and 12 meters, which cater to most usage requirements. During transportation and storage, welded pipes often need to be cut; thus, selecting different lengths based on specific needs is practical.

-

2024-06-12Product News

Production principle of hot-rolled seamless steel pipe

The production of hot-rolled seamless steel pipes involves rolling solid ingots into hollow tubes without seams. This process is applicable to carbon steel, alloy tubes, high alloy steel, and some non-ferrous metals. The resulting seamless steel pipes have an outer diameter range of 16 to 1600 mm and a wall thickness of 2 to 200 mm.

-

2024-06-12Product News

Rust removal methods of LSAW steel pipe

In the anti-corrosion construction process for pipelines, the surface treatment of LSAW (Longitudinal Submerged Arc Welding) steel pipes is crucial for determining the longevity of the pipes. This surface treatment ensures a solid bond between the pipe and its anti-corrosion layer. Studies have shown that, aside from the type of coating, the quality of coating, and environmental factors during construction, the surface treatment of LSAW steel pipes accounts for approximately 50% of the coating’s lifespan. Therefore, adhering to stringent surface treatment standards is essential. The main methods for rust removal in LSAW steel pipes are as follows.