-

2024-04-19Product News

3 LPE pipe, three-layer polyethylene coated steel pipe according to DIN 30670 standard

Three-layer polyethylene (3LPE) is a multi-layer coating composed of three functional ingredients: a high-performance fused-bonded epoxy (FBE) primer, a copolymer adhesive and a polyethylene outer layer that provides a tough, long-lasting protection of. 3LPE systems provide excellent pipe protection for small and large diameter pipes operating at moderately high temperatures

-

2024-04-12Product News

Three-Layer Polypropylene (3LPP) Coated Line Pipe

USI STEEL can produce 3LPP 3-layer polypropylene coating for API 5L PSL 1 & PSL 2 line pipe, from NPS 2" to NPS 56" (60.3mm - 1422.4mm), if you have such inquiry, welcome to contact us.

Three-layer polypropylene (3LPP) coating The 3LPP coating system is a multi-layer coating composed of three functional components: high-performance fused epoxy (FBE), copolymer binder and medium density polypropylene (MDPP) or an outer layer of high-density polypropylene (HDPP) to protect against external corrosion.

-

2024-04-11Product News

Pre-insulated steel pipe

Maximum operating temperature is 142°C (150°C short-term), maximum operating overpressure is 2.5 MPa, and service life is 30 years. PUR foam insulated pipes with heat resistance up to 165°C available on request.

-

2024-03-29Product News

API 5L X46 Pipe Specifications

The minimum yield strength of API 5L X46 pipe is approximately 317 MPA. These grades of pipe have chemical and mechanical properties superior to API 5L Grade B and API 5L X42 Grade pipe. This grade is known for its heavy-duty and high performance, making it cost-effective. Due to their high mechanical strength, these pipes have a robust structure, high resistance to cuts and precise dimensions. API 5L grade PSL1 X46 pipe is often chosen by customers looking for better performance than grade B and X42 pipe.

-

2024-03-27Product News

API 5L X42 Pipe Specifications

API 5L X42 pipe has a minimum yield strength of 290 MPA, enabling it to operate in low to medium pressure pipes. These grades of pipe are superior to API 5L Grade B pipe in terms of chemical and mechanical properties. It has higher mechanical strength than API 5L Class B pipe and is therefore less susceptible to cracking. For industrial applications requiring higher strength pipes, customers prefer API 5L GR. X42 pipe replaces API 5L Class B.

-

2024-03-22Product News

About X60 line pipe introduction

API 5L Psl1 Line Pipe covers seamless and welded carbon steel line pipes suitable for transporting natural gas and petroleum industries. Our company can provide high-quality API5L Gr.b line pipe with API certificate to the world. API 5L gr.b ERW steel pipe is a very common steel grade, usually psl1 gr.b pipe.

-

2024-03-19Product News

Spiral Welded Pipe and ERW Pipe

Manufacturing process

A.ERW pipe manufacturing process:

Electric resistance welded (ERW) pipe is produced using a relatively simple but efficient manufacturing process. It starts with flat steel strip unrolled from a roll and passed through a series of rollers to ensure uniform thickness. The strip then enters the welding chamber, where high-frequency current is applied to the edges of the strip. This localized heating causes the edges to melt and fuse together, forming a continuous weld. Finally, the welded pipe is cut to the required length and subjected to various finishing processes such as straightening and inspection.

-

2024-03-01Product News

What Is Q235 Carbon Steel?

Q235 Steel (Q235A Q235B Q235C Q235D)

Q235 steel is a common carbon structural steel widely used in my country. The Q235 material in Chinese standard GB/T 700 is divided into 4 quality grades: Q235A, Q235B, Q235C and Q235D; the density of the steel is 7.85 g/cm3, and the tensile strength is 370-500 MPa; Yield strength is 235MPa (data is for steel bars or steel plates with a diameter less than or equal to 16mm). Since it is mild steel, it can be used directly without heat treatment.

-

2024-03-01Product News

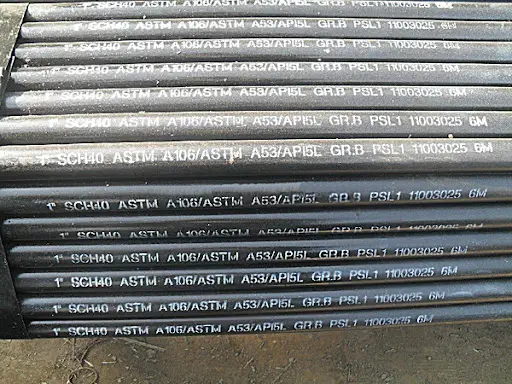

A106 GR.B seamless steel pipe

A106 GR.B seamless steel pipe is a high-quality steel pipe that is widely used in the petroleum, chemical, and boiler industries. The material has good mechanical properties. A106B American standard seamless pipe complies with the ASTM A106/A106M carbon steel seamless steel pipe standard for high-temperature operation, grade B.

-

2024-02-25Product News

The Difference Between Hot-Dip Galvanized Pipe And Pre-Galvanized Pipe

The Difference Between Hot-Dip Galvanized Pipe And Pre-Galvanized Pipe

1. What Is Hot Dip Galvanizing?

Hot dip galvanizing is the process of immersing metal in a molten zinc bath. To make galvanized steel using this method, we need to follow 4 steps: surface cleaning, fluxing, hot dip plating and cooling.

-

2024-01-26Product News

Performance of stainless steel pipes

The special properties of stainless steel pipes are:

1. Excellent corrosion resistance: A thin protective film will form on the surface of stainless steel. Although this protective film is about 3×10-6 mm, it is very strong. Even if it is damaged, as long as there is oxygen next to it, it will It can be regenerated immediately to prevent rust.

-

2024-01-26Product News

Operation steps for pickling and passivation of stainless steel welded pipes

he operation steps of pickling and passivating stainless steel pipe welded pipes are divided into the following 8 points:

1. Preparation

2. Chemical degreasing

3. Rinse with hot water...