-

2023-10-16Product News

API Oil Casing Thread Connection

API oil casing threaded connection usually consists of two parts: pipe or external thread end and coupling or internal thread end. Those with external threads are called pipes or male ends, and those with internal threads are called pipe joints or female ends. Today, we will briefly introduce the threaded connection of API oil casing.

-

2023-10-13Product News

Packaging Precaution of ERW Steel Pipe

ERW (Electric Resistance Welded) steel pipes are commonly used in various industries for transporting liquids and gases. Proper packaging is essential to ensure that these pipes are protected during transportation and storage. Here are some packaging precautions for ERW steel pipes.

-

2023-10-13Product News

API 5L Line Pipe Heat Treatment Process

Line pipes are widely used to transport oil, gas, oil products and water. The common standard is API 5L. According to the different performance requirements of API 5L line pipes and the different tempering temperatures, tempering can be divided into the following types.

-

2023-10-11Product News

Testing Items For Seamless Carbon Steel Pipes

Seamless carbon steel pipe, as its name suggests, has no welds. Therefore, the detection of seamless carbon steel pipes is particularly important. Today, we will introduce some common seamless carbon steel pipe testing items.

-

2023-10-11Product News

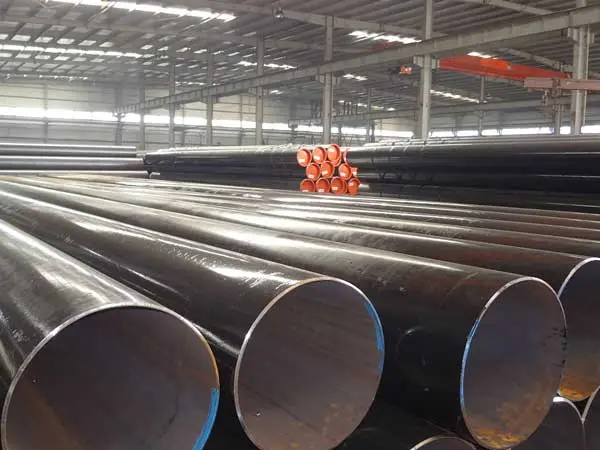

Spiral Steel Pipe Anti-Corrosion Work In Summer

For conventional spiral steel pipes (SSAW Steel Pipe), summer is a season that is prone to corrosion. Because the atmospheric humidity increases in summer and the rainy weather increases, steel pipes are often exposed to wind, rain and scorching sun. This article will briefly introduce how to perform anti-corrosion work on spiral steel pipes in summer.

-

2023-10-10Product News

API 5L LSAW Steel Pipe

API 5L (American Petroleum Institute 5L) refers to a set of standards that specify the requirements for the manufacture of steel pipes and pipelines used in the transportation of oil, gas, and other fluids. LSAW stands for Longitudinal Submerged Arc Welded, which is a specific type of welding method used in the production of steel pipes. LSAW pipes are commonly used in the construction of large-diameter pipelines. Here are some key points about API 5L LSAW steel pipes.

-

2023-10-10Product News

ASTM A252 Steel Pipe Pile Specifications

Pipe piles are needed to form deep foundations for buildings and bridges when soil and ground conditions are not suitable to support the structure to be built. Pipe piles are typically used in deep foundations to transfer structural loads to rock formations or stronger soil conditions deep underground. Piles are also used to form foundations and prevent erosion when building roads, bridges, docks and buildings in coastal areas. Today, we will discuss ASTM A252 steel pipe piles specifications.

-

2023-10-09Product News

How To Check The Physical Properties Of Seamless Carbon Steel Pipes?

Carbon seamless steel pipes are made of carbon steel, alloy steel, stainless steel ingots or solid tube blanks, and are made by hot rolling, cold rolling or cold drawing. Because they are manufactured from a solid billet of steel with no welds, they have inherent mechanical strength. Today, we will discuss how to check the physical properties of seamless carbon steel pipes.

-

2023-10-09Product News

A Simple Guide to Duplex and Super Duplex Stainless Steel Pipe

Duplex stainless steel pipe has high strength, light weight, corrosion resistance, and at the same time, the price fluctuates very little. Therefore, it is now very popular and commonly used around the world and is usually an economical solution for pipeline applications. Super duplex steel pipe has the high strength of ferrite structure and the high corrosion resistance of austenitic structure, achieving an excellent combination of strength and corrosion resistance. They have good toughness and resistance to stress corrosion cracking, are readily available, and are more competitive than other corrosion-resistant metals that use higher levels of expensive alloy additives.

-

2023-10-08Product News

ASTM A234 Pipe Fittings

ASTM A234 is the standard specification for steel pipe fittings suitable for use in moderate and high temperature environments, including carbon and alloy steel materials, covering both seamless and welded types of steel fittings. Today, we will introduce ASTM A234 pipe fittings in detail.

-

2023-10-07Product News

Elbow Rust Prevention Guide

Affected by factors such as different construction conditions, elbows need to take appropriate anti-rust measures to extend their service life. Let’s take a look at how to prevent elbows from rusting.

-

2023-10-07Product News

Stainless Steel Pipe Fittings Processing Technology

Stainless steel pipe fittings are widely used in different fields, such as: petrochemical industry, food and medicine, shipbuilding and aviation, etc. Below, United Steel Industry will introduce the processing technology of stainless steel pipe fittings from three aspects: processing flow, process requirements and quality control.