-

2023-11-21Product News

ERW Welded Pipe Technical Standard

Electric Resistance Welded (ERW) pipes are a type of welded steel pipe that is produced by continuously forming a flat steel strip into a tubular shape and then welding the edges together using electrical resistance. Various technical standards govern the production and quality requirements of ERW welded pipes. The following are some commonly referenced technical standards for ERW welded pipes.

-

2023-11-21Product News

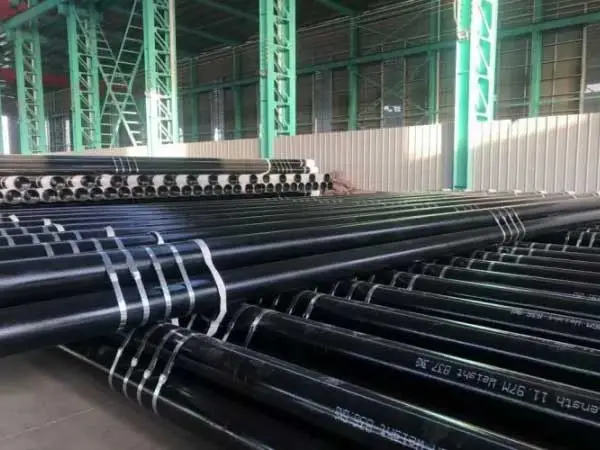

J55 Oil Casing Production Process

The production process for J55 oil casing involves several steps to manufacture high-quality steel casing suitable for use in oil and gas wells. J55 is a common grade of casing steel, and its production process generally includes the following key stages.

-

2023-11-20Product News

Anticorrosion FBE Coated SSAW Steel Pipe

Fusion-Bonded Epoxy (FBE) coated SSAW (Submerged Arc Welded) steel pipes are designed to provide corrosion protection for pipelines. The FBE coating is applied to the external surface of the steel pipe through a fusion-bonding process, creating a durable and protective layer. Here are key points about FBE coated SSAW steel pipes.

-

2023-11-20Product News

Hydrostatic Test of Seamless Boiler Pipe

Seamless boiler pipes frequently operate under elevated temperatures and pressures, subject to the corrosive effects of high-temperature flue gas and water vapor. In this harsh environment, the pipelines are prone to oxidation and corrosion. To ensure optimal performance, steel pipes must exhibit exceptional durability, resistance to oxidation and corrosion, and robust structural stability. Consequently, the hydrostatic testing of seamless boiler pipes holds significant importance. Today, we will provide a comprehensive overview of the hydrostatic pressure testing process applied to seamless boiler pipes.

-

2023-11-20Product News

API 5CT Oil Casing Steel Grade

API 5CT oil casing specification defines various steel grades to meet the specific requirements of different well conditions. Each steel grade has distinct mechanical properties and is suitable for particular well environments. In this article, United Steel Industry will introduce the most common API 5CT oil casing steel grades.

-

2023-11-17Product News

How to Protect the Anode and Cathode of Oil Casing Pipe?

With the swift advancement of the petroleum industry, the substantial corrosion observed in buried pipelines, oil well casings, and storage tank floors, particularly in oil well casings, has posed significant challenges to the production, development, and environmental integrity of oil fields. Safeguarding the cathode and anode of oil casings typically involves implementing anti-corrosion measures aimed at prolonging the casing's operational life. Let's briefly explore how to shield the anode and cathode of oil casings.

-

2023-11-17Product News

3PE Coating Anticorrosive Steel Pipe

3PE coating, which stands for Three-Layer Polyethylene, is an anticorrosive coating applied to steel pipes to protect them from corrosion and extend their service life. This coating system is widely used in various industries, including oil and gas, water transportation, and underground pipelines. United Steel Industry will briefly introduce 3PE coated anticorrosive steel pipe in this passage.

-

2023-11-17Product News

Carbon Steel Seamless Pipe VS Stainless Steel Seamless Pipe

Carbon steel seamless pipes and stainless steel seamless pipes are two distinct types of pipes with different compositions, characteristics, and applications. Below is a comparison of these two types of seamless pipes.

-

2023-11-16Product News

Oil Casing Steel Grade and Acceptance Standard

Oil casing refers to the steel pipe used to support the wall of oil and gas wells during drilling and after completion. The selection of steel grade for oil casing is critical, and it must meet certain acceptance standards to ensure the integrity and safety of the well. The American Petroleum Institute (API) sets the standards for oil casing steel grades and acceptance criteria. Below are some common oil casing steel grades and the corresponding API standards.

-

2023-11-16Product News

Common Drill Pipe Connection

Drill pipe connections are crucial components in the drilling industry, providing the means to connect individual sections of drill pipe and form a continuous drill string. Several common drill pipe connections are used in the industry, each with its unique design and features. In this article, United Steel Industry will introduce some of the commonly used drill pipe connections.

-

2023-11-16Product News

5 Heat Treatment Processes for Seamless Steel Pipes

Heat treatment is a critical process in the manufacturing of seamless steel pipes, as it helps achieve desired mechanical properties and performance characteristics. Here are 5 common heat treatment processes for seamless steel pipes.

-

2023-11-15Product News

Heat Treatment of LSAW Steel Pipe

Longitudinal Submerged Arc Welded (LSAW) steel pipes may undergo heat treatment to improve their mechanical properties and relieve internal stresses resulting from the welding process. The heat treatment process for LSAW steel pipes typically involves two main procedures: normalization and stress relief annealing. This article will talk about heat treatment of LSAW steel pipe.