-

2024-12-11Product News

What are pipe clamps used for?

Pipe clamps are versatile devices used to secure, support, and stabilize pipes in various applications. They are commonly used in construction, plumbing, HVAC (heating, ventilation, and air conditioning), and industrial settings. Here are the main uses of pipe clamps.

-

2024-12-11Product News

How to polish stainless steel pipe?

Polishing stainless steel pipes involves several steps to achieve a smooth, shiny, and reflective surface. Here's a general guide to polishing stainless steel pipe.

-

2024-12-10Product News

How to weld galvanized pipe?

Welding galvanized pipe requires special care because the galvanized coating (typically zinc) can cause issues during the welding process. The zinc coating can release toxic fumes, affect the integrity of the weld, and cause poor welding results if not properly managed. Below is a step-by-step guide to welding galvanized pipe safely and effectively.

-

2024-12-10Product News

What is mechanical tubing?

Mechanical tubing refers to a type of pipe or tubing specifically designed for mechanical and structural applications, rather than for fluid or gas transportation. It is made from a variety of metals, including steel, stainless steel, and aluminum, and is often used in the manufacturing of machinery, automotive, construction, and industrial equipment. The primary difference between mechanical tubing and standard pipe is that mechanical tubing is manufactured to meet specific mechanical properties and dimensional tolerances, making it ideal for applications where strength, durability, and precision are required.

-

2024-12-09Product News

What is concrete weight coating?

Concrete Weight Coating (CWC) is a type of protective coating applied to steel pipes, primarily used in pipeline construction to provide ballast and prevent buoyancy, ensuring the pipes stay in place during installation and transportation, particularly in underwater or marine environments. The concrete layer also provides protection against mechanical damage and corrosion, making it an essential part of pipeline systems that operate in challenging conditions such as offshore oil and gas pipelines or subsea water transport.

-

2024-12-09Product News

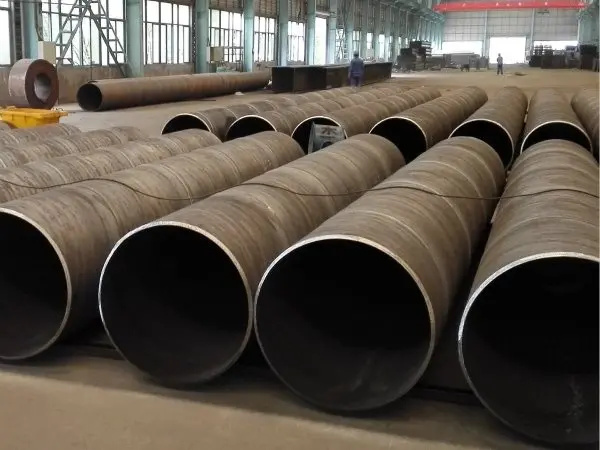

What is EFW pipe?

EFW pipe, or Electric Fusion Welded Pipe, is a type of welded steel pipe that is produced by using an electric fusion welding process. The manufacturing process involves the use of high-frequency electrical current to heat the edges of the steel plate or coil, which are then fused together to form a strong and seamless bond. This welding method is commonly used to produce pipes for various applications in industries such as construction, oil and gas, water distribution, and infrastructure projects.

-

2024-12-06Product News

Boiler tube standard specifications

Boiler tubes are critical components in pressure vessels and boilers, requiring adherence to stringent standards to ensure safety, reliability, and durability. Various countries and organizations have established their own specifications for boiler tubes to meet diverse industrial requirements. Below is an overview of these specifications categorized by regional and organizational standards.

-

2024-12-06Product News

Nondestructive testing of boiler steel pipes

The interior of boiler steel pipes often contains hard-to-detect defects, such as lack of fusion, incomplete penetration, slag inclusions, pores, and cracks in the welds. Since destructive testing of every boiler or pressure vessel is impractical, nondestructive testing (NDT) methods are essential. These methods assess internal structures and defects by examining changes in physical properties without damaging the workpiece.

-

2024-12-04Product News

Applications of carbon steel pipes in pipeline engineering

With the rapid advancement of industrialization, pipeline engineering has become a vital component across various industries. As a key material for pipeline construction, carbon steel pipes are highly regarded for their exceptional properties and versatility. This article highlights the characteristics of carbon steel pipes, their extensive applications in pipeline engineering, and the challenges associated with their use.

-

2024-12-04Product News

Application of carbon steel pipes in the automotive field

Carbon steel pipes are essential components in the automobile manufacturing process, valued for their high strength, excellent wear resistance, and cost-effectiveness. Their versatility makes them widely used across various automotive systems. Below is an in-depth look at the types of carbon steel pipes used in automobiles and their applications.

-

2024-12-03Product News

Specifications and models of pipe piles

Pipe piles are a versatile and widely used construction material in various fields. They are primarily composed of steel or concrete pipes, with additional equipment such as swing arms and hooks added based on specific project requirements. Below are the common specifications and models for pipe piles.

-

2024-12-03Product News

In what projects are pipe piles used?

Pipe piles are long, narrow cylindrical structural elements typically made from steel pipes or reinforced concrete pipes. They are widely used in foundation reinforcement and support for various engineering structures, including buildings, bridges, and other infrastructure projects.