-

2024-12-04Product News

Application of carbon steel pipes in the automotive field

Carbon steel pipes are essential components in the automobile manufacturing process, valued for their high strength, excellent wear resistance, and cost-effectiveness. Their versatility makes them widely used across various automotive systems. Below is an in-depth look at the types of carbon steel pipes used in automobiles and their applications.

-

2024-12-03Product News

Specifications and models of pipe piles

Pipe piles are a versatile and widely used construction material in various fields. They are primarily composed of steel or concrete pipes, with additional equipment such as swing arms and hooks added based on specific project requirements. Below are the common specifications and models for pipe piles.

-

2024-12-03Product News

In what projects are pipe piles used?

Pipe piles are long, narrow cylindrical structural elements typically made from steel pipes or reinforced concrete pipes. They are widely used in foundation reinforcement and support for various engineering structures, including buildings, bridges, and other infrastructure projects.

-

2024-12-02Product News

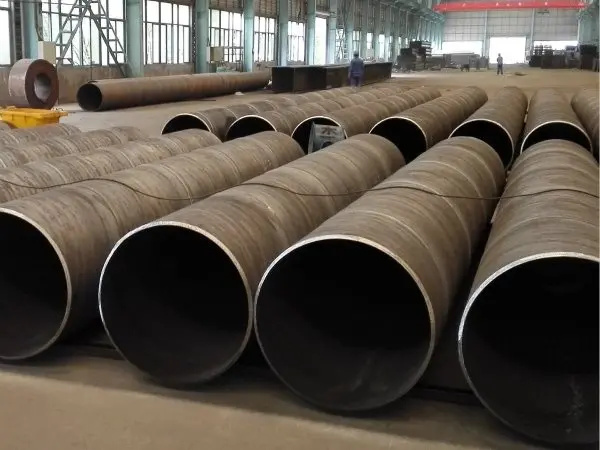

Spiral steel pipe connection skills

Spiral steel pipes, or SSAW steel pipes, are welded pipes made from strip steel coils as raw materials, which are extruded at a regular temperature and welded using an automatic double-wire, double-sided submerged arc welding process. The quality of the joint in SSAW pipes directly affects the strength and sealing performance of the connection. Here are some essential operational tips and key considerations for ensuring seamless, misalignment-free joints.

-

2024-12-02Product News

Details of SSAW steel pipe for drainage application

The drainpipe typically uses SSAW (Spiral Submerged Arc Welded) steel pipe, which is manufactured using the submerged arc welding method. The spiral weld creates a continuous seam, which helps distribute the pressure from the liquid inside the pipe evenly across the pipe's surface, enhancing the strength of the SSAW steel pipe. In contrast, if straight seam steel pipes (such as ERW pipes) were used, larger steel plates would be required to form the pipe, complicating the manufacturing process and increasing costs.

-

2024-11-26Product News

Advantages of LSAW steel pipe JCOE forming

The JCOE process is one of the key forming techniques used in the production of straight seam steel pipes. It involves several steps such as bending, jointing, internal welding, external welding, straightening, and flattening. These processes ensure that the final product meets the relevant industry standards. The steel pipe's inner and outer surfaces must be smooth, free from defects such as folding, cracks, delamination, lap welding, arc breakage, or burn-through. Any local defects with a depth exceeding the lower wall thickness deviation are not allowed, though minor defects within acceptable limits are permissible.

-

2024-11-26Product News

Pre-welding technology of LSAW steel pipe

LSAW (Longitudinal Submerged Arc Welded) steel pipes are produced by rolling a single medium or thick steel plate into a cylindrical shape using a mold or forming machine, followed by double-sided submerged arc welding. This process not only joins the edges of the plate but also expands the pipe diameter. One critical aspect of the LSAW steel pipe production process is the pre-welding stage, where the forming seam is subjected to "shallow welding" along the entire length of the pipe. This specialized technique is essential to ensure the integrity of the final welded pipe.

-

2024-11-25Product News

Cold crack for ERW steel pipe

Cold cracks are a type of defect that may occur in Electric Resistance Welded (ERW) steel pipes during or after the welding process. These cracks are a significant quality concern as they can compromise the structural integrity and reliability of the pipe.

-

2024-11-25Product News

ERW steel pipe market analysis

Electric Resistance Welded (ERW) steel pipes are widely used across various industries due to their cost-effectiveness, efficiency, and adaptability. Below is an analysis of the ERW steel pipe market, considering current trends, drivers, challenges, and future outlook.

-

2024-11-22Product News

What are the advantages of pipe clamps?

Pipe clamps offer several advantages, making them indispensable in a wide range of applications. Here's an overview of benefits of pipe clamps.

-

2024-11-22Product News

How do pipe clamps work?

Pipe clamps are versatile tools used to secure and support pipes in various applications, from plumbing and construction to industrial and mechanical systems. Here's an overview of how pipe clamps work.

-

2024-11-21Product News

Top 10 advantages of steel sheet piles

Steel sheet piles are among the most versatile and efficient materials in modern construction. Known for their durability, adaptability, and environmental benefits, they are widely used in projects such as retaining walls, cofferdams, and flood defenses. Below is an expanded list of the top advantages of using steel sheet piles in various engineering and construction applications.