-

2025-01-09Product News

Purposes of 316L stainless steel pipes leveling process

The leveling process is an essential step in the manufacturing of 316L stainless steel pipes, designed to enhance the mechanical properties, shape, and surface quality of the material. This process addresses various challenges that arise during production and ensures the pipes meet the requirements for diverse applications. Below are the main purposes of the leveling process of 316L stainless steel pipes.

-

2025-01-09Product News

How to remove weld spots from 304 stainless steel pipes?

Welded pipes, particularly those made from 304 stainless steel, often exhibit orange, blue, or black weld spots after welding. These spots are challenging to remove and can negatively impact the pipe’s appearance, accelerate atmospheric corrosion, and reduce corrosion resistance, ultimately affecting its performance. Here are four effective methods to remove weld spots and improve the quality of 304 stainless steel pipes.

-

2025-01-08Product News

Solution treatment of stainless steel seamless pipes

Stainless steel seamless pipes are crucial materials in modern industries, including petroleum, chemicals, food, and medicine. However, the production process of stainless steel seamless pipes, which involves rolling, drawing, and welding, can alter the material's structure and mechanical properties. This often affects the pipe's overall quality. To address these issues, solution treatment has become an essential process in enhancing the performance of stainless steel seamless pipes.

-

2025-01-08Product News

Market competition for stainless steel seamless pipes

Stainless steel seamless pipes are a key material in various industries due to their durability and high performance. Manufactured through a seamless process, these pipes are free of welds, offering superior strength and reliability. As an essential material across sectors like petroleum, chemicals, and natural gas, the stainless steel seamless pipe market faces increasing competition. Let’s explore the current competitive landscape and future trends shaping the market.

-

2025-01-07Product News

Will 304 stainless steel pipes rust in the soil?

304 stainless steel pipes are widely used across various industries due to their excellent corrosion resistance, high temperature tolerance, and strong mechanical properties. Their ability to withstand the effects of most chemical media, including acids, alkalis, and salt solutions, makes them highly suitable for applications in construction, chemical industries, oil and gas, food processing, and more.

-

2025-01-07Product News

The implementation standard of 304 stainless steel seamless pipes

304 stainless steel seamless pipes are a key material in many industries, including chemical, pharmaceutical, food, and shipbuilding, due to their excellent corrosion resistance and mechanical properties. To maintain the stable quality of these pipes and meet the diverse needs of different industries, China has established a series of implementation standards that regulate their production, quality control, and usage processes.

-

2025-01-06Product News

How to choose a suitable storage warehouse for large-diameter steel pipes?

When storing large-diameter steel pipes, it is essential to select an appropriate warehouse that provides adequate protection and maintains the integrity of the materials. Proper storage conditions ensure that the steel pipes remain in optimal condition, preventing corrosion, contamination, and physical damage. Below are key considerations for choosing the right storage warehouse for large-diameter steel pipes.

-

2025-01-06Product News

Industrial DN150 galvanized steel pipe details

The DN150 galvanized steel pipe, with a diameter of 150 mm, is known for its excellent corrosion resistance and robust strength. It is widely used in construction, engineering, petrochemical industries, and other fields where reliable and durable piping systems are essential. Galvanized steel pipes are produced by applying a layer of zinc to the surface of ordinary steel pipes, enhancing their ability to resist corrosion and extend their service life.

-

2025-01-03Product News

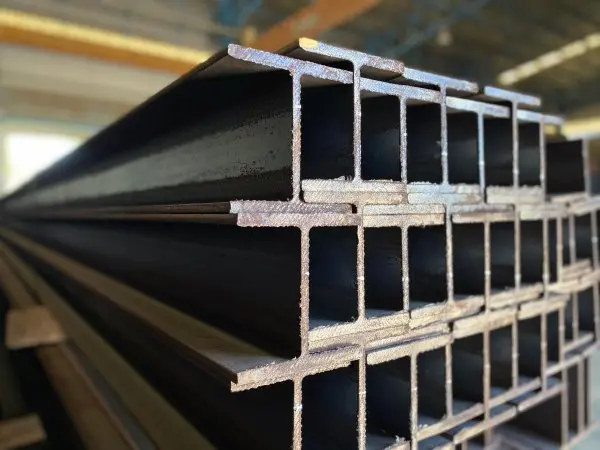

What is h beam?

An H-beam is a structural steel beam commonly used in construction and civil engineering projects. Its name comes from its “H”-shaped cross-section, which provides excellent strength and stability. It is also known as a wide flange beam due to the width of its flanges, which distinguish it from other beam types, such as I-beams.

-

2025-01-03Product News

What is Q235 steel grade?

Q235 is a common carbon structural steel grade in China, often used in construction and industrial applications due to its balance of strength, plasticity, and weldability. Its properties make it versatile for various uses in manufacturing, building structures, and fabrication.

-

2025-01-02Product News

How to connect two threaded pipes?

Connecting two threaded pipes requires proper alignment, sealing, and tightening to ensure a secure and leak-proof connection. This article will talk about how to connect two threaded pipes.

-

2025-01-02Product News

What pipe to use for pipe clamps?

The type of pipe to use with pipe clamps depends on the application, environment, and material compatibility. Below are common types of pipes and their suitability for use with pipe clamps.