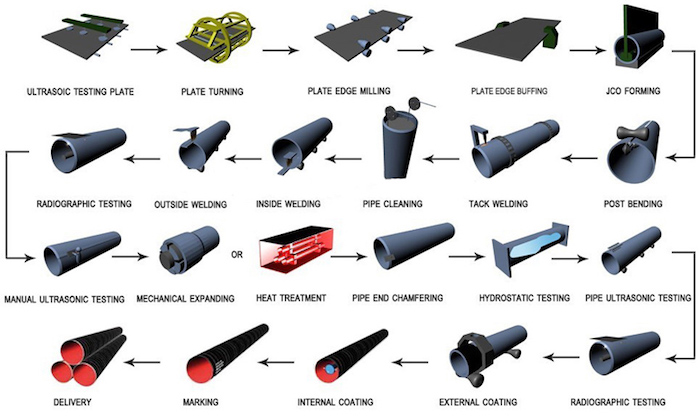

LSAW steel pipe Production Process

1. Plate detection: After the steel plate enters the production line, the whole plate ultrasonic inspection is first carried out, and the raw materials for the production of steel pipes are strictly checked.

2. Edge milling: use the automatic edge milling machine to perform double-sided milling on the two longitudinal sides of the steel plate to make it reach the required plate width. The edge milling machine has the function of automatic centering of the steel plate, and the milling head has the function of floating profiling tracking, which can Automatically adjust the position of the milling head according to the flatness of the steel plate to ensure that both sides of the steel plate have the same groove shape and size. the16. Anti-corrosion and coating: According to user requirements, the steel pipes that have passed the inspection are treated for anti-corrosion and coating.